Organosilicon polyethylene glycol hydrogel material with self-healing characteristic and preparation method thereof

A polyethylene glycol and organosilicon technology, which is applied in the field of organosilicon hydrogels, can solve the problems of high preparation cost, poor self-healing performance, and inconvenient preparation methods, and achieves simple preparation process, low cost and environmentally friendly preparation, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

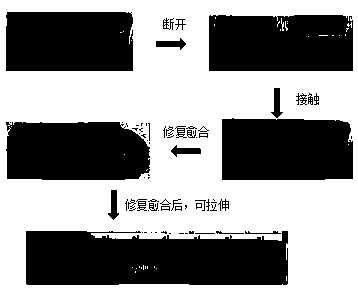

Image

Examples

Embodiment 1

[0044] (1) Preparation of reaction solution

[0045] Disperse amino silicone oil (average molecular weight 80000g / mol, ammonia value 0.6) in deionized water to obtain an aqueous solution of component A amino silicone oil with a mass percent concentration of 6%; amino-terminated polyethylene glycol (average molecular weight 2000g / mol) was dissolved in deionized water to obtain an aqueous solution of amino-terminated polyethylene glycol of component B with a mass percent concentration of 5%; N,N'-thiocarbonyldiimidazole was dissolved in deionized water to obtain a mass percent concentration 8% C component N,N'-thiocarbonyldiimidazole aqueous solution;

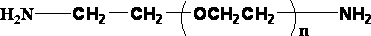

[0046] Wherein, the structural formula of amino-terminated polyethylene glycol aqueous solution is:

[0047]

[0048] (2) Preparation of pre-polymerization solution

[0049] Mix 100g of component B and 800g of component C, stir evenly, and react at 60°C for 2 hours to obtain a prepolymer solution;

[0050] (3) Preparation ...

Embodiment 2

[0055] (1) Preparation of reaction solution

[0056] Disperse amino silicone oil (average molecular weight 20000g / mol, ammonia value 1.0) in deionized water to obtain an aqueous solution of component A amino silicone oil with a mass percent concentration of 2%; amino-terminated polyethylene glycol (average molecular weight 6000g / mol) was dissolved in deionized water to obtain an aqueous solution of amino-terminated polyethylene glycol of component B with a mass percentage concentration of 4%; N,N'-thiocarbonyldiimidazole was dissolved in deionized water to obtain a mass percentage concentration 8% C component N,N'-thiocarbonyldiimidazole aqueous solution;

[0057] Wherein, the structural formula of amino-terminated polyethylene glycol aqueous solution is:

[0058]

[0059] (2) Preparation of pre-polymerization solution

[0060] Mix 100g of component B and 6g of component C, stir evenly, and react at 40°C for 5h to obtain a prepolymer solution;

[0061] (3) Preparation o...

Embodiment 3

[0066] (1) Preparation of reaction solution

[0067] Disperse amino silicone oil (average molecular weight 100000g / mol, ammonia value 0.3) in deionized water to obtain an aqueous solution of component A amino silicone oil with a mass percent concentration of 30%; amino-terminated polyethylene glycol (average molecular weight 800g / mol) was dissolved in deionized water to obtain an aqueous solution of amino-terminated polyethylene glycol of component B with a mass percent concentration of 1%; N,N'-thiocarbonyldiimidazole was dissolved in deionized water to obtain a mass percent concentration 5% aqueous solution of component C N,N'-thiocarbonyldiimidazole;

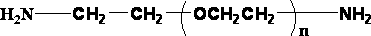

[0068] Wherein, the structural formula of amino-terminated polyethylene glycol aqueous solution is:

[0069]

[0070] (2) Preparation of pre-polymerization solution

[0071] Mix 100g of component B and 20g of component C, stir evenly, and react at 30°C for 8 hours to obtain a prepolymer solution;

[0072] (3) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com