Coal-based fully-synthetic SN-grade lubricating oil and preparation method thereof

A fully synthetic, lubricating oil technology, applied in the field of lubricating oil, can solve the problem of high production cost, and achieve the effects of reduced production cost, high oil film thickness and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

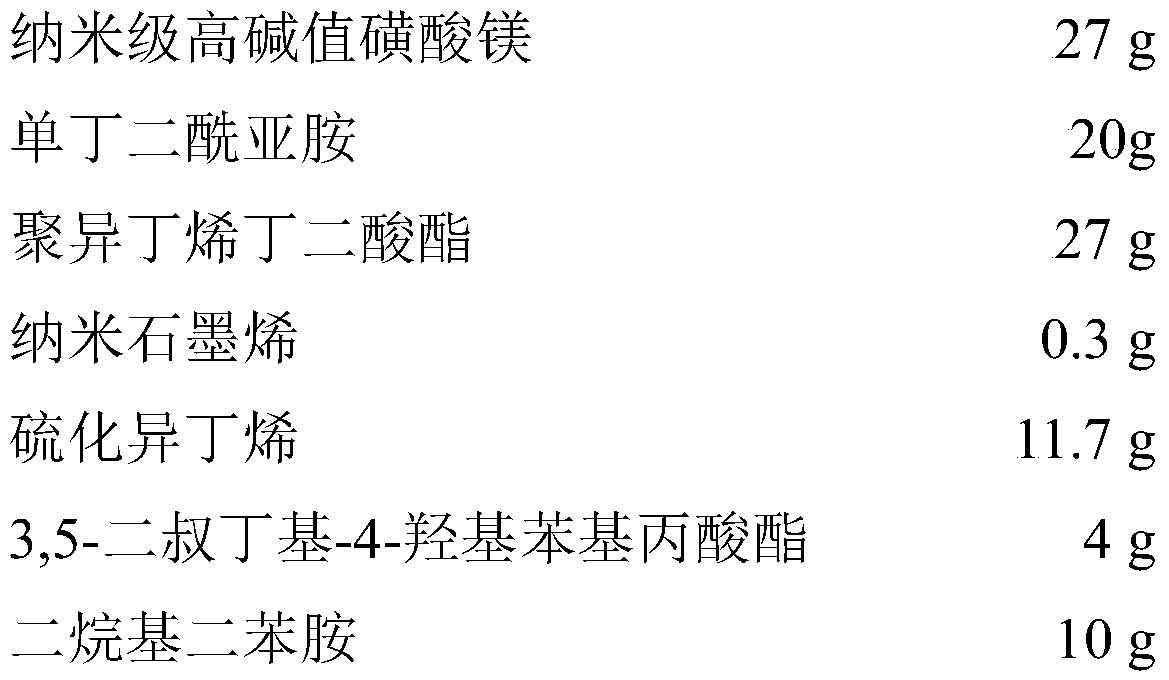

[0038] First, prepare the gasoline engine oil compound according to the following formula:

[0039]

[0040] Add functional additives into a three-necked flask according to the above proportions, heat to 60° C. and stir for 1.5 hours, and ultrasonically oscillate for 30 minutes to obtain a gasoline engine oil compounding agent.

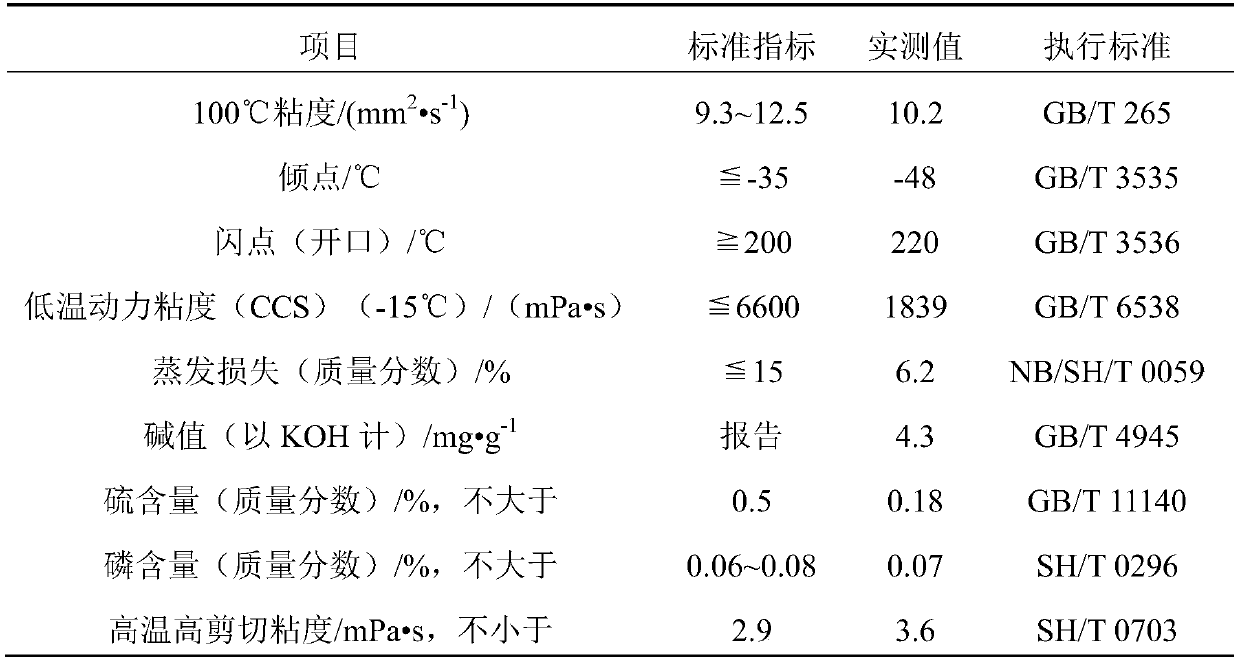

[0041] Weigh 50g of 1# coal-based base oil and 35g of 2# coal-based base oil into a three-necked flask, raise the temperature to 50°C, and keep the temperature constant for 1h. Continue to add gasoline engine oil compounding agent 7.48g, pour point depressant (PMA: 0.1g; polyalphaolefin: 0.4g), viscosity index improver (hydrogenated styrene 7g), composite antifoaming agent (polyacrylate 0.02g). Stir at constant temperature for 2 hours under the condition of 300r / min, and finally obtain 1# product oil after ultrasonic oscillation for 30 minutes. The basic physical and chemical properties of the obtained lubricating oil were tested and analyzed, and...

Embodiment 2

[0046] First, prepare the gasoline engine oil compound according to the following formula:

[0047]

[0048] Add functional additives into a three-necked flask according to the above proportions, heat to 60° C. and stir for 1.5 hours, and ultrasonically oscillate for 30 minutes to obtain a gasoline engine oil compounding agent.

[0049]Weigh 55g of 1# coal-based base oil and 28g of 2# coal-based base oil into a three-necked flask, raise the temperature to 50°C, and keep the temperature constant for 1h. Continue to add gasoline engine oil compounding agent 8.38g, pour point depressant (PMA: 0.2g; polyalphaolefin: 0.4g), viscosity index improver (hydrogenated styrene 8g), composite antifoaming agent (polyacrylate 0.02g). Stir at constant temperature for 2 hours under the condition of 300r / min, and finally obtain 2# product oil after ultrasonic oscillation for 30 minutes. The basic physical and chemical properties of the obtained lubricating oil were tested and analyzed, and ...

Embodiment 3

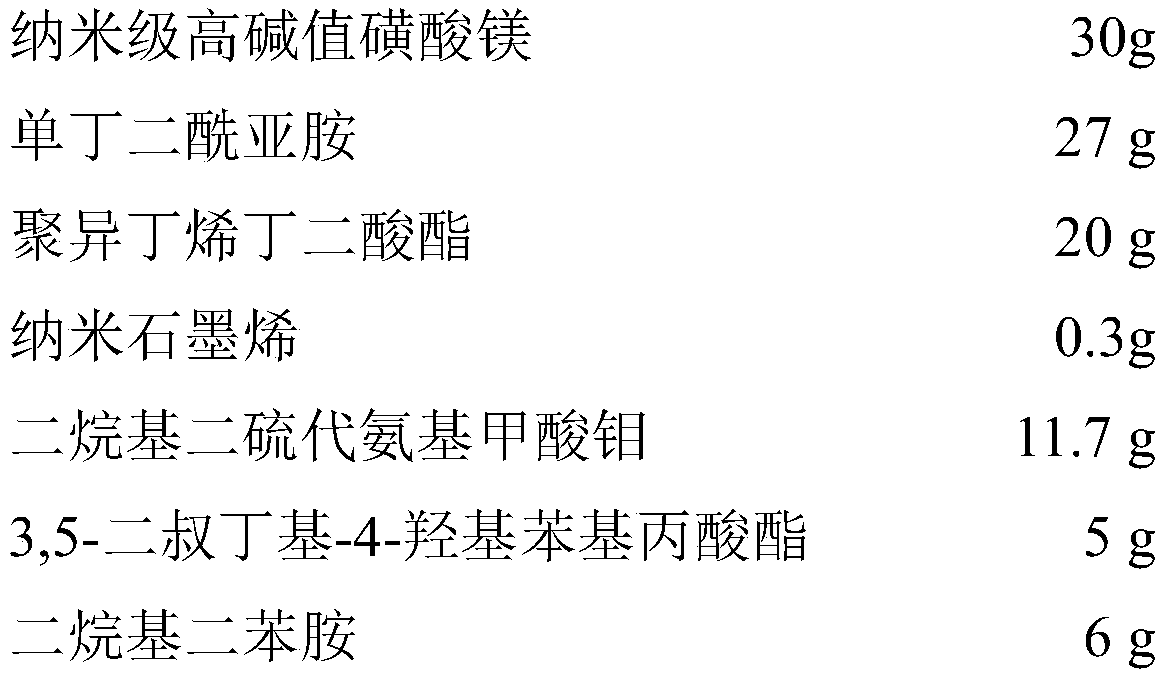

[0054] First, prepare the gasoline engine oil compound according to the following formula:

[0055]

[0056]

[0057] Add functional additives into a three-necked flask according to the above proportions, heat to 60° C. and stir for 1.5 hours, and ultrasonically oscillate for 30 minutes to obtain a gasoline engine oil compounding agent.

[0058] Weigh 50g of 1# coal-based base oil and 30g of 2# coal-based base oil into a three-necked flask, raise the temperature to 50°C, and keep the temperature constant for 1h. Continue to add compounding agent 9.58g, pour point depressant (PMA: 0.1g; polyalphaolefin: 0.3g), viscosity index improver (hydrogenated styrene 10g), composite antifoaming agent (polyacrylate 0.02g). Stir at a constant temperature for 2 hours under the condition of 300r / min, and finally obtain 3# product oil after ultrasonic oscillation for 30 minutes. The basic physical and chemical properties of the obtained lubricating oil were detected and analyzed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com