Power supply control method and system for logging-while-drilling detection pipe in underground coal mine

A logging-while-drilling and power control technology, which is applied to mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of discontinuous and unreliable logging data, and achieve data discontinuity, avoid invalid work, and prolong The effect of power-on time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

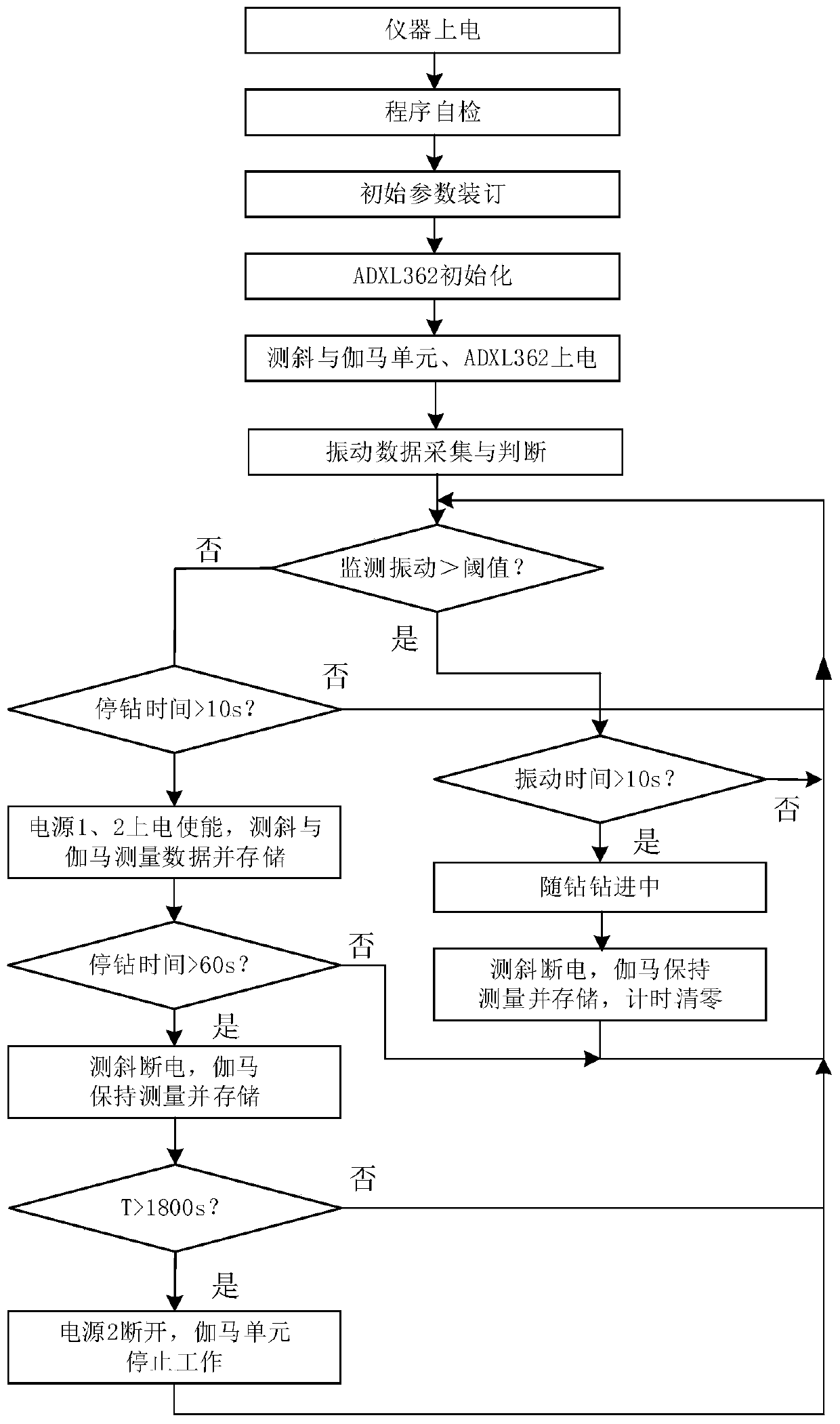

[0038] Such as figure 1 Shown is a flow chart of a method for controlling the power source of a logging-while-drilling probe in a coal mine disclosed in this embodiment. First, power on the LWD probe for the first time to ensure that both the inclinometer unit and the gamma detection unit are working normally, and then perform the following control process:

[0039] Monitoring the vibration of the LWD probe;

[0040] If the detected vibration is not greater than the preset vibration threshold, and the duration t1 , the gamma detection unit and the inclinometer unit of the logging carbon tube both maintain the state of the previous moment (that is, dormancy or power supply); if the duration T 1 ≤t2 , execute process A; if the duration T 2 ≤t3 , execute B process; if the vibration state lasts for t≥T 3 , Execute the C procedure.

[0041] If the monitored vibration is greater than the preset vibration threshold, the state lasts for t1 , execute C process; the vibration state ...

Embodiment 2

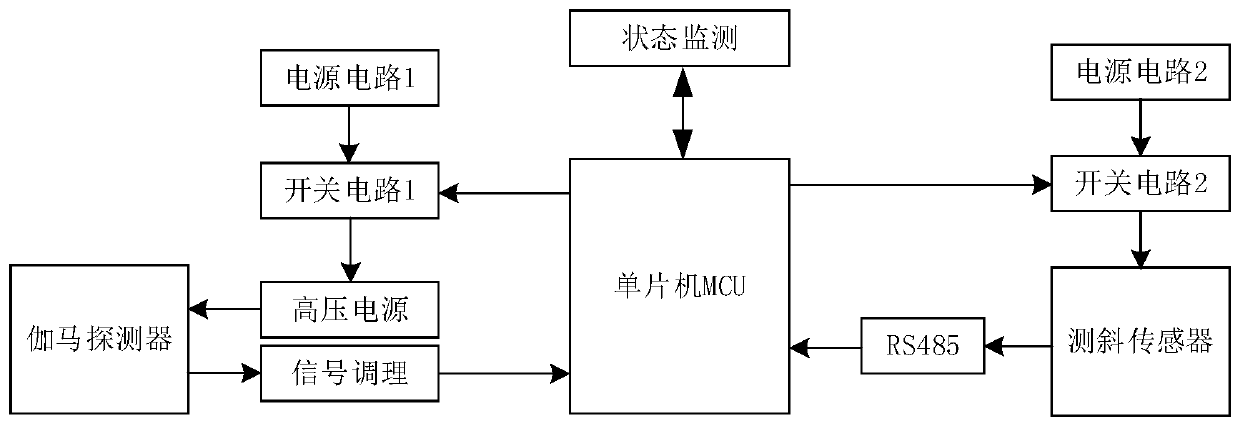

[0052] This embodiment discloses a coal mine logging-while-drilling probe power supply control system, and the system includes the following modules:

[0053] The vibration monitoring module is used to monitor the vibration of the LWD probe;

[0054] The state judging module is used for judging whether the vibration value of the logging-while-drilling probe is greater than the threshold and the duration is t1 , T 1 ≤t2 , T 2 ≤t3 or t≥T 3 ;

[0055] The power supply control module of the inclinometer unit and the gamma detection unit is used to determine that the vibration is not greater than the preset vibration threshold and the duration t1 When , control the inclinometer unit and the gamma detection unit to maintain the state at the previous moment,

[0056] Or according to the state judging module, it is judged that the vibration is not greater than the preset vibration threshold and the duration is T 1 ≤t2 When the power is supplied to both the control inclinometer uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com