A mining method of cutting coal forward and back filling in the open-pit side

A mining method and side-side technology, which is applied in open-pit mine mining, filling, ground mining, etc., can solve problems such as ineffective recovery of coal resources, disasters caused by side-side stability, and loss of coal resources, etc., to reduce coal consumption. Production cost and labor intensity of workers, improvement of mining efficiency and production safety, and effect of reducing surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

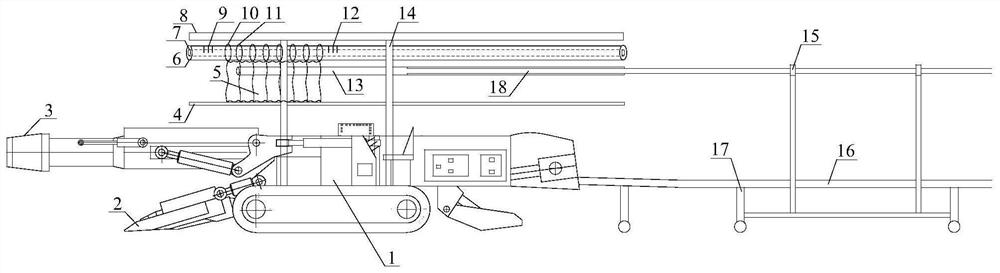

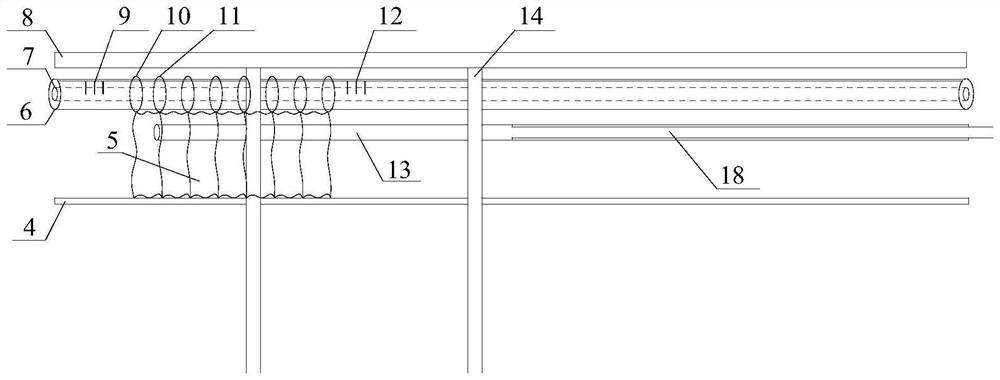

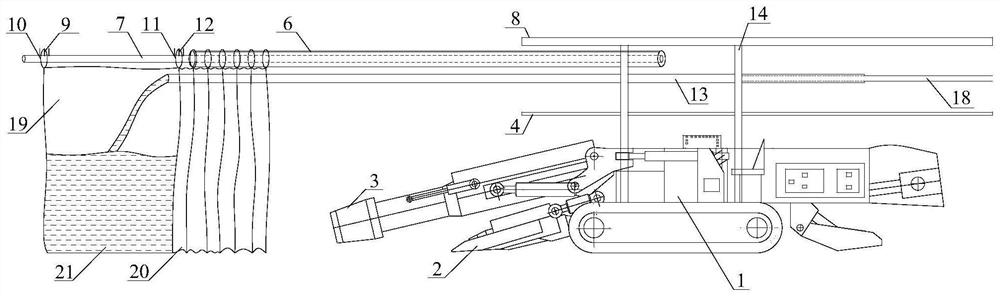

[0029] 1. The roadheader 1 advances from the bottom of the side pit to excavate and cut coal, and then uses the loading mechanism 2 to transport the falling coal through the scraper chain in the roadheader 1 to the coal conveyor belt, and finally transports the coal through the coal conveyor 16. out of the roadway;

[0030] 2. When the roadheader 1 is about 15m deep, stop the system, and connect a section of frame and belt to the frame 17 of the coal conveyor belt machine outside the roadway, and at the same time, connect a section of frame and belt to the L-shaped pipe frame 15 on the side of the frame Install and inject the slurry pipeline 18, every 15m a cycle, so repeatedly, until driving to stop production line;

[0031] 3. When the roadheader 1 advances to the stop production line, the roadheader 1 automatically lowers the cutting head 3, and the bag-hanging arm 6, telescopic arm 7, lower baffle plate 4 and telescopic slurry injection pipe 13 on the filling device move f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com