Sealed cavity-based rotating shaft threaded water sealing structure

A cavity-sealing and water-sealing technology, which is applied in engine sealing, wear resistance testing, instruments, etc., can solve problems such as endangering the operation of the unit, destroying the profile of the blade, and reducing the efficiency of the cascade, so as to reduce the roughness, reduce the The effect of small processing difficulty and simple thread structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

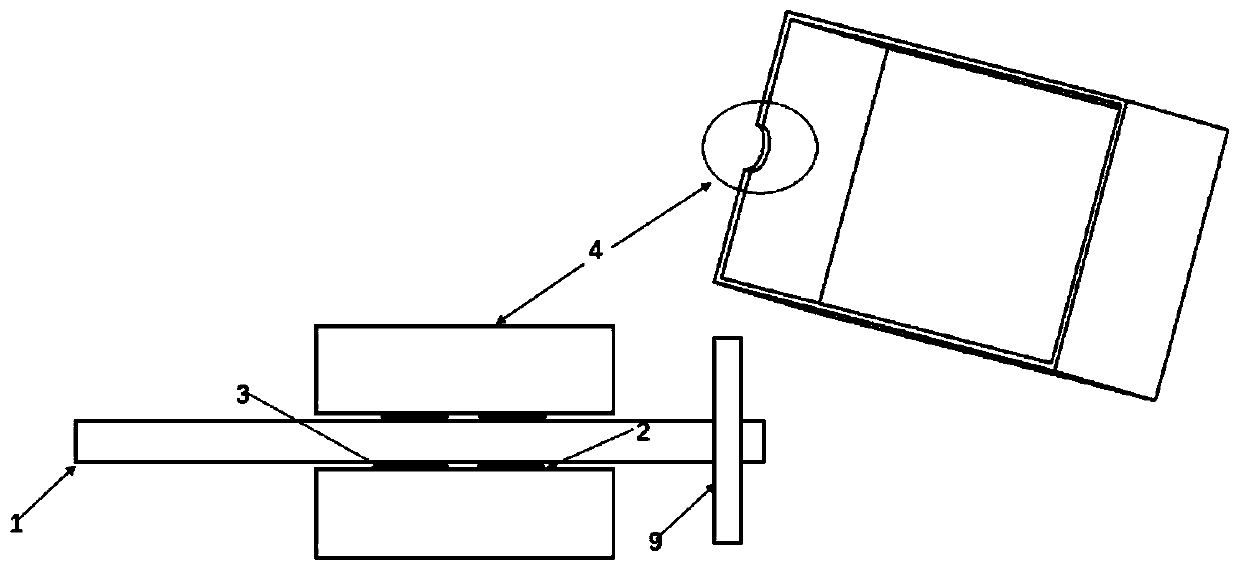

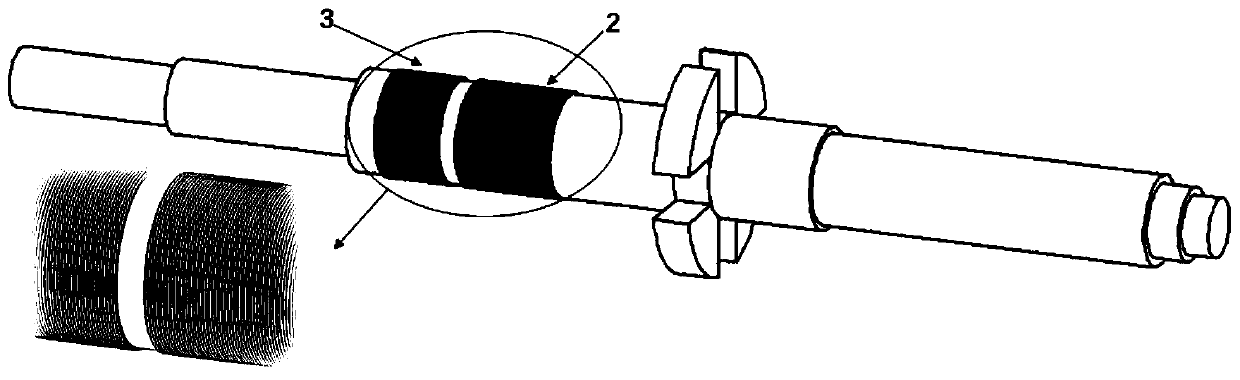

[0029] see figure 1 , the present invention provides a shaft threaded water seal structure based on a sealed cavity, the main structural parts involved in its action include the shaft 1, the double-headed rectangular right-handed thread structure 2 and the four-headed rectangular left-handed thread structure processed integrally with the shaft 1 The screw structure 3 and the cavity 4 through which the rotating shaft 1 passes. Wherein, it can be seen from the simplified sectional view of the cavity 4 that the rotating shaft 1 only passes through the left end of the cavity 4, and its connecting part is also the area where the threaded water seal structure works. figure 1 It is only a simplified connection schematic diagram of the threaded water seal structure of the rotating shaft. For the actual structural design and thread distribution of the rotating shaft, please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com