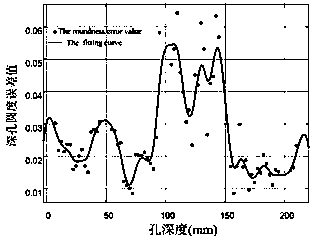

Method for monitoring hole roundness error in deep hole drilling in real time

A roundness error, real-time monitoring technology, applied in the field of real-time monitoring of deep hole machining process, can solve the problems of secondary damage, inability to globally detect, low efficiency, etc., and achieve the effect of low cost, important engineering practical value, and strong real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

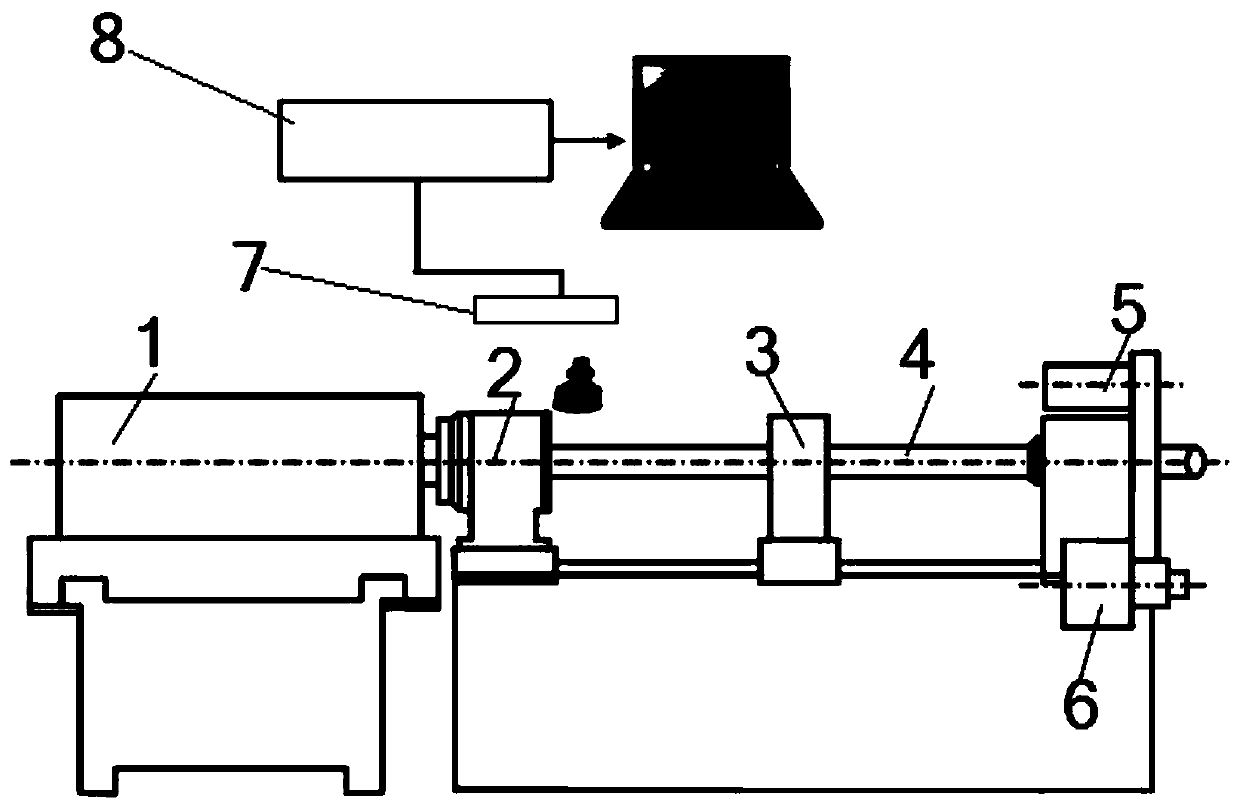

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

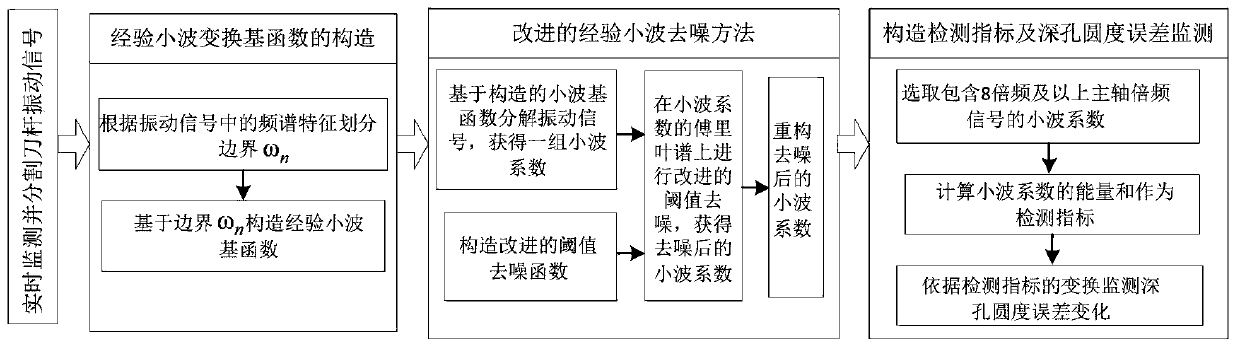

[0048] A method for real-time monitoring of hole roundness errors in deep hole drilling, characterized in that it comprises the following steps:

[0049] Step 1. Acquisition of the vibration signal of the tool bar in deep hole drilling: through the eddy current displacement sensor, with a sampling frequency of 1600Hz, the vibration signal f(x) of the tool bar closest to the workpiece in deep hole drilling is collected in real time;

[0050] Step 2. Construct an improved empirical wavelet threshold noise reduction method, apply it to the vibration signal of the cutter bar, and realize the extraction and noise reduction of the 8-fold and above-fold frequency signal of the spindle rotation frequency in the vibration signal;

[0051] The concrete process of described step 2 is as follows:

[0052] Step 2.1, obtain the frequency spectrum f(ω) of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com