Novel four-switch five-level inverter

A five-level, four-switch technology, applied in the field of new four-switch five-level inverters, can solve the problems of reducing device power density, increasing device volume, and increasing device cost, so as to reduce switching loss and reduce device volume , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can better understand the present invention.

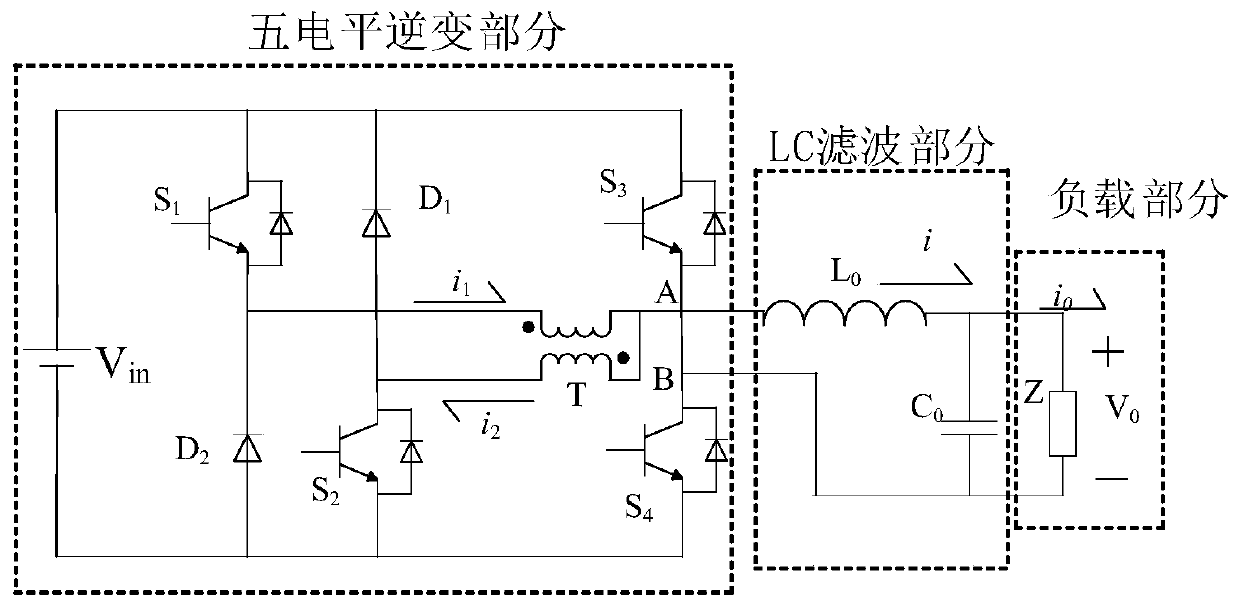

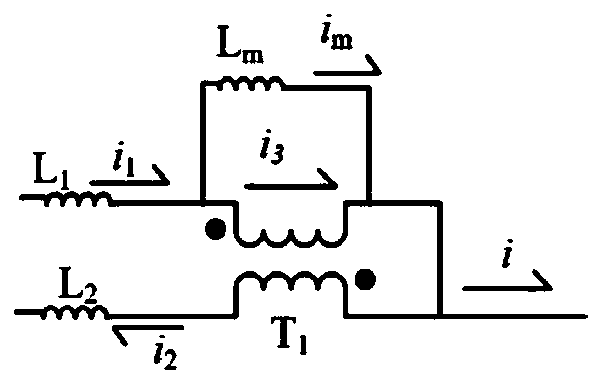

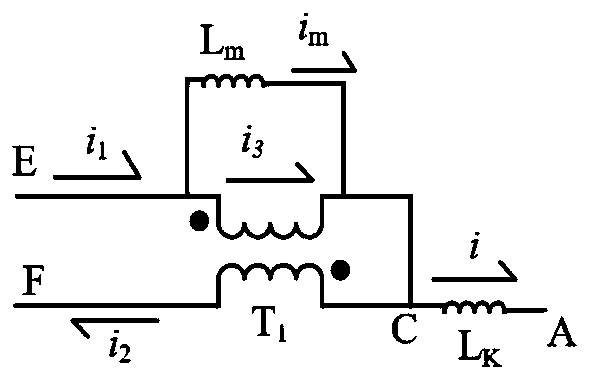

[0038]The present invention proposes a novel single-phase five-level inverter topology. The inverter has three bridge arms in structure, wherein the first and second bridge arms are respectively composed of a switching device and a diode connected in series. Two of the four ports of the polar coupling reactor are respectively connected to the two bridge arms, and the equivalent inductance of the leakage inductance of the coupling reactor is connected in series with the output filter inductance, which effectively reduces the total harmonics of the output current / voltage Distortion rate (THD), improved power quality. In the working mode, using the voltage equalization characteristics of the reverse polarity coupling reactor, only 4 switching devices and fewer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com