Dry-wet separation dosing device

A technology of dosing device and dry-wet separation, which is applied in feeding device, mixer with rotary stirring device, transportation and packaging, etc. In order to improve the efficiency and improve the quality and efficiency of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

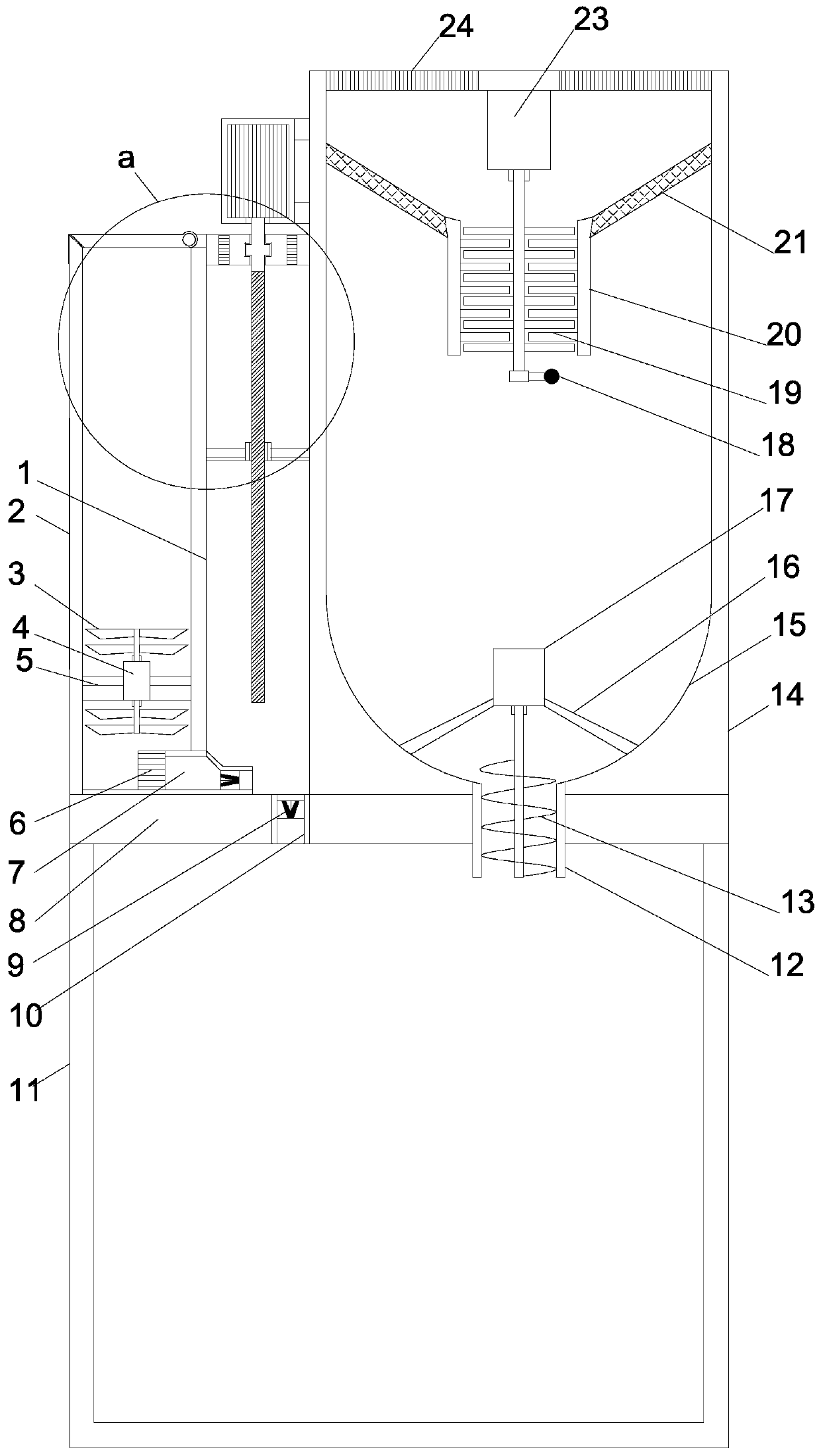

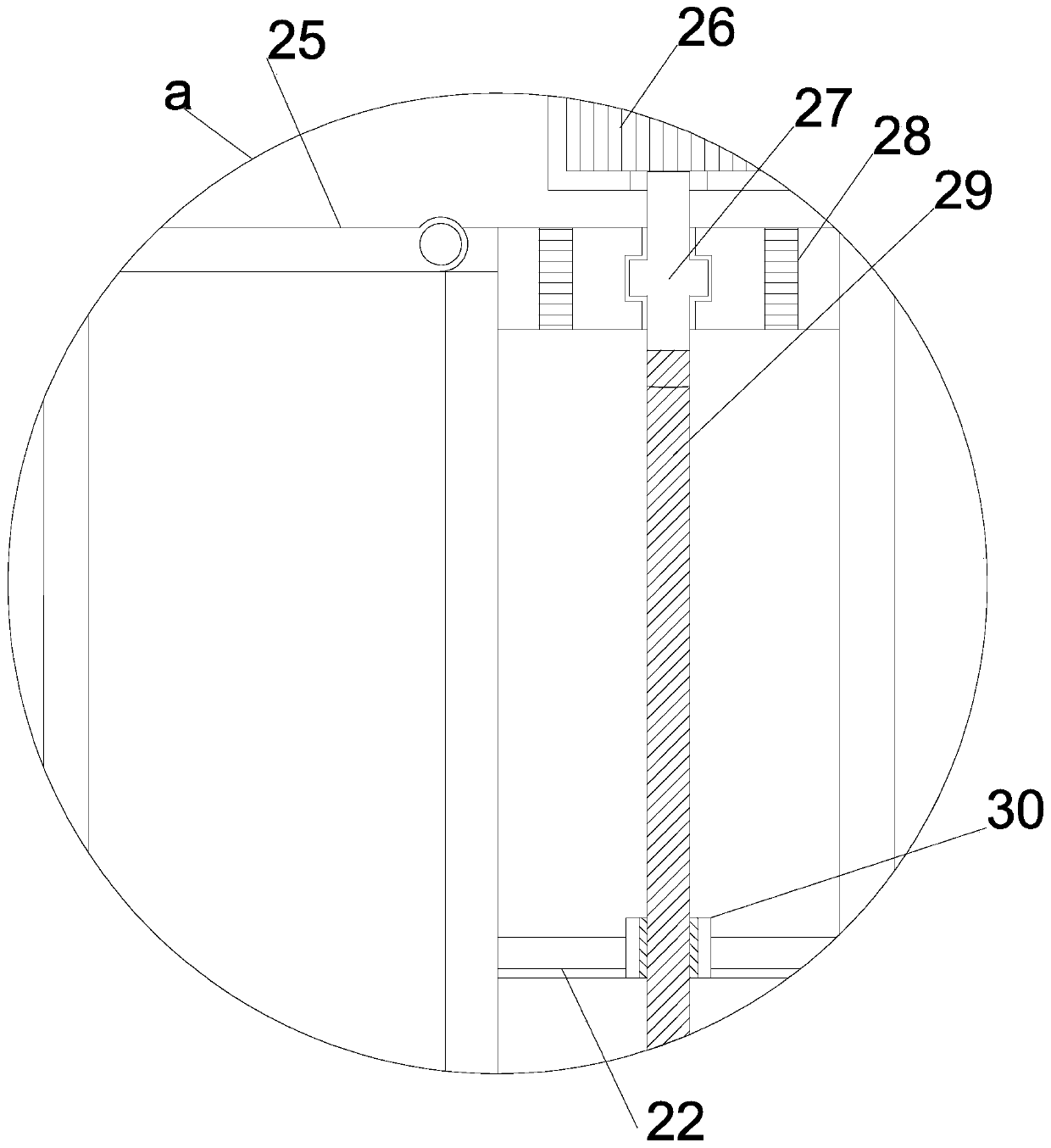

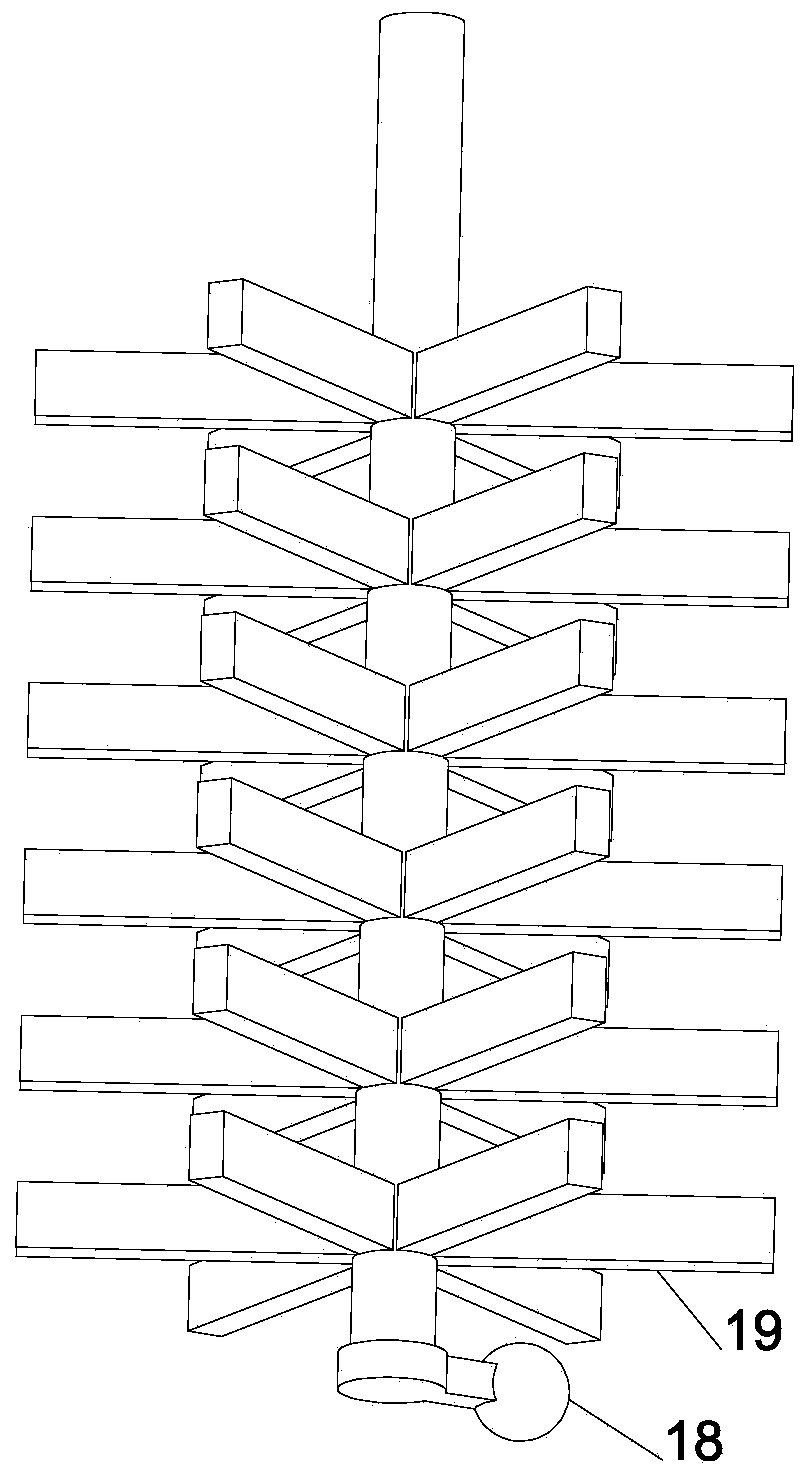

[0021] see Figure 1~3 , in an embodiment of the present invention, a dry-wet separation type dosing device includes a vertically arranged reaction installation cylinder 11, the upper end of the reaction installation cylinder 11 is horizontally provided with a support installation plate 8, and the upper right end of the support installation plate 8 is vertically A support installation cylinder 14 is provided, and the upper left end of the support installation plate 8 is vertically provided with a liquid inlet installation cylinder 2, and a diversion piston cylinder 1 is vertically arranged between the liquid inlet installation cylinder 2 and the support installation cylinder 14. A crushing motor 23 is arranged vertically downward at the middle position of the top of the cylinder 14, and a number of feed holes 24 are arranged at an equal angle on the top of the supporting installation cylinder 14 outside the crushing motor 23, and a crushing installation cylinder 20 is verticall...

Embodiment 2

[0024] On the basis of Embodiment 1, the raw materials in the liquid inlet installation cylinder 2 are mixed and stirred under the rotation of the stirring impeller 3 driven by the mixing motor 4, so that the liquid raw materials maintain fluidity and are evenly mixed, and the one-way valve 9 ensures The device can transport materials in one direction, and the eccentric rotating column 18 rotates synchronously with the crushing column 19, which makes the device vibrate, accelerates the material guiding process, and improves the operating efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com