Suturing and detecting mechanism of solar water heater water tank liner and a suturing and detecting process

A technology of solar water heaters and detection mechanisms, which is applied in the direction of manufacturing tools, metal processing equipment, and other manufacturing equipment/tools, etc., can solve the problems of grinding parts that cannot be welded, and achieve the effects of improving quality, smooth connection, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

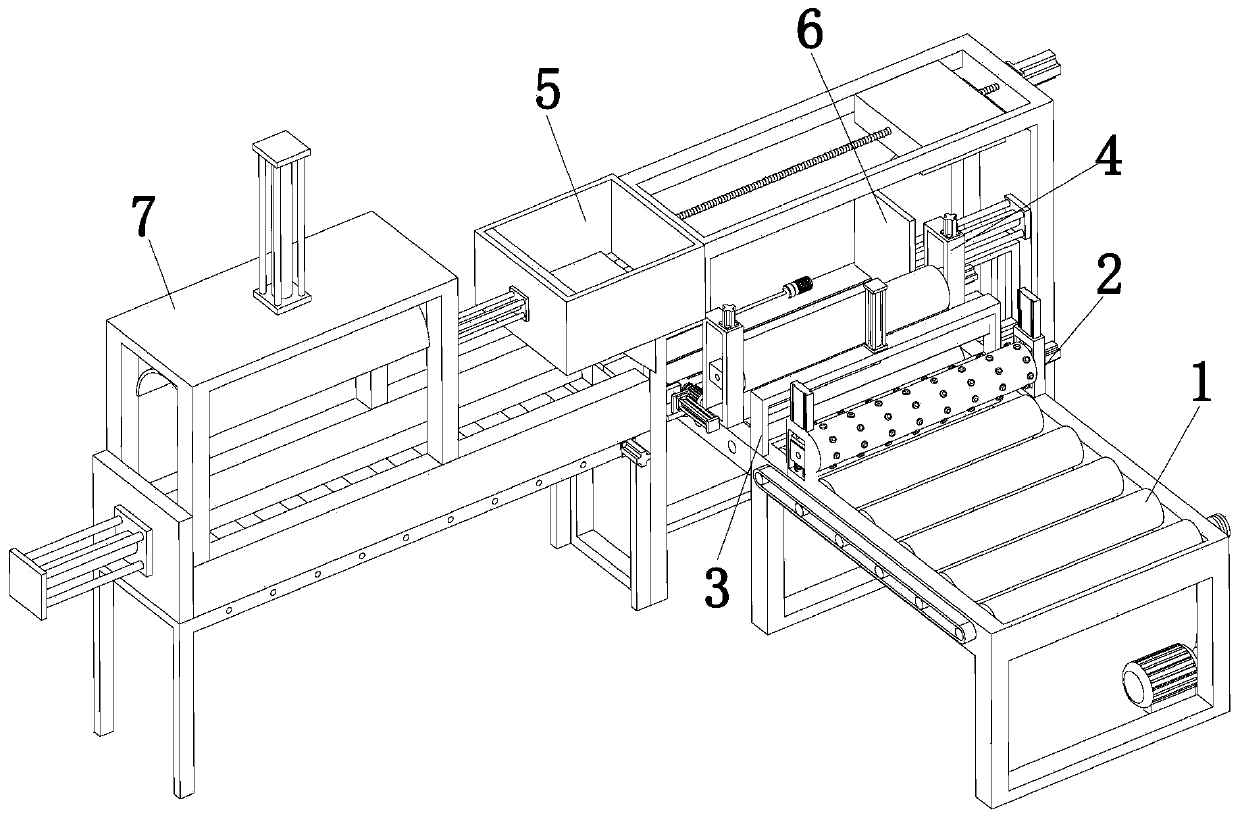

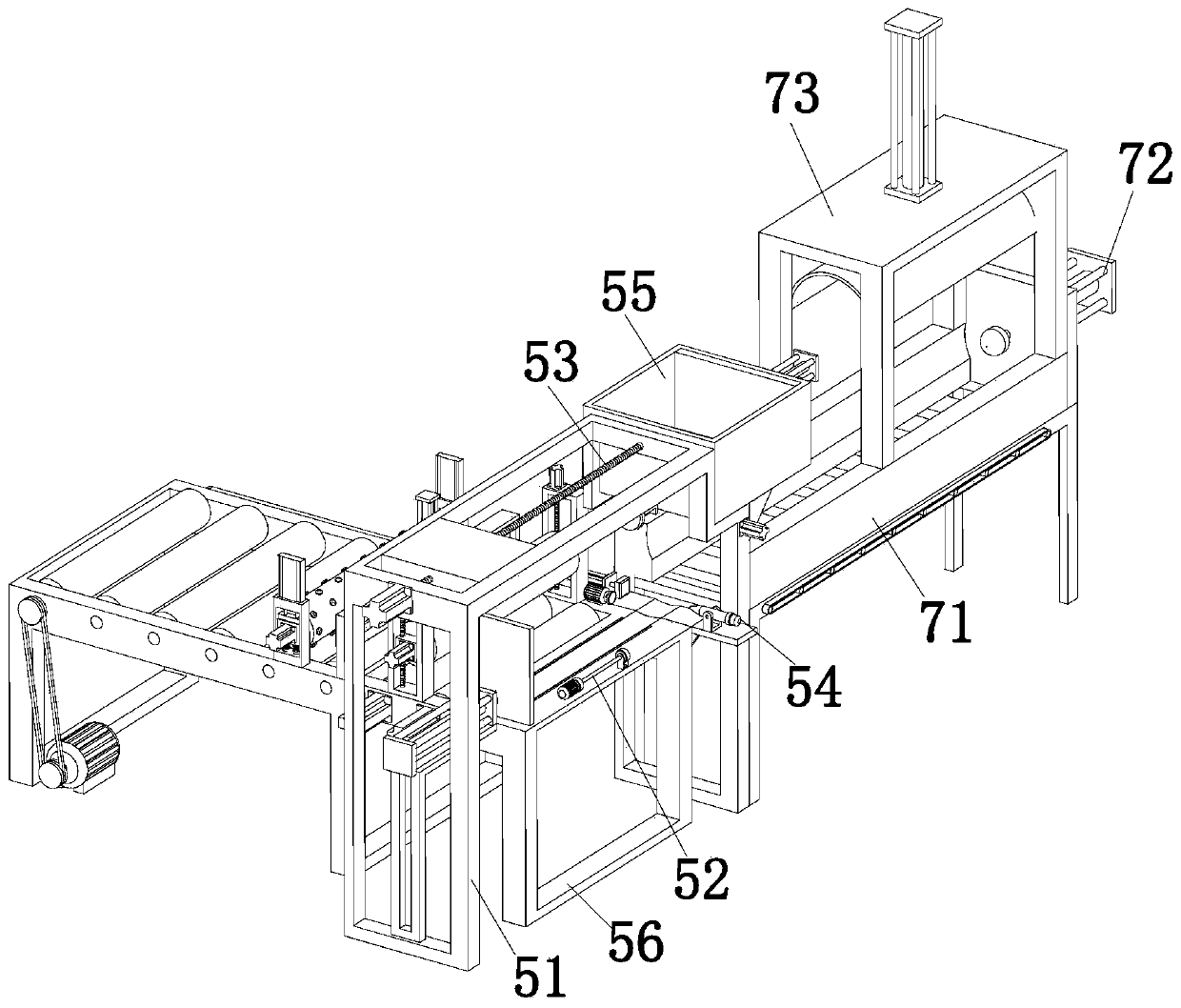

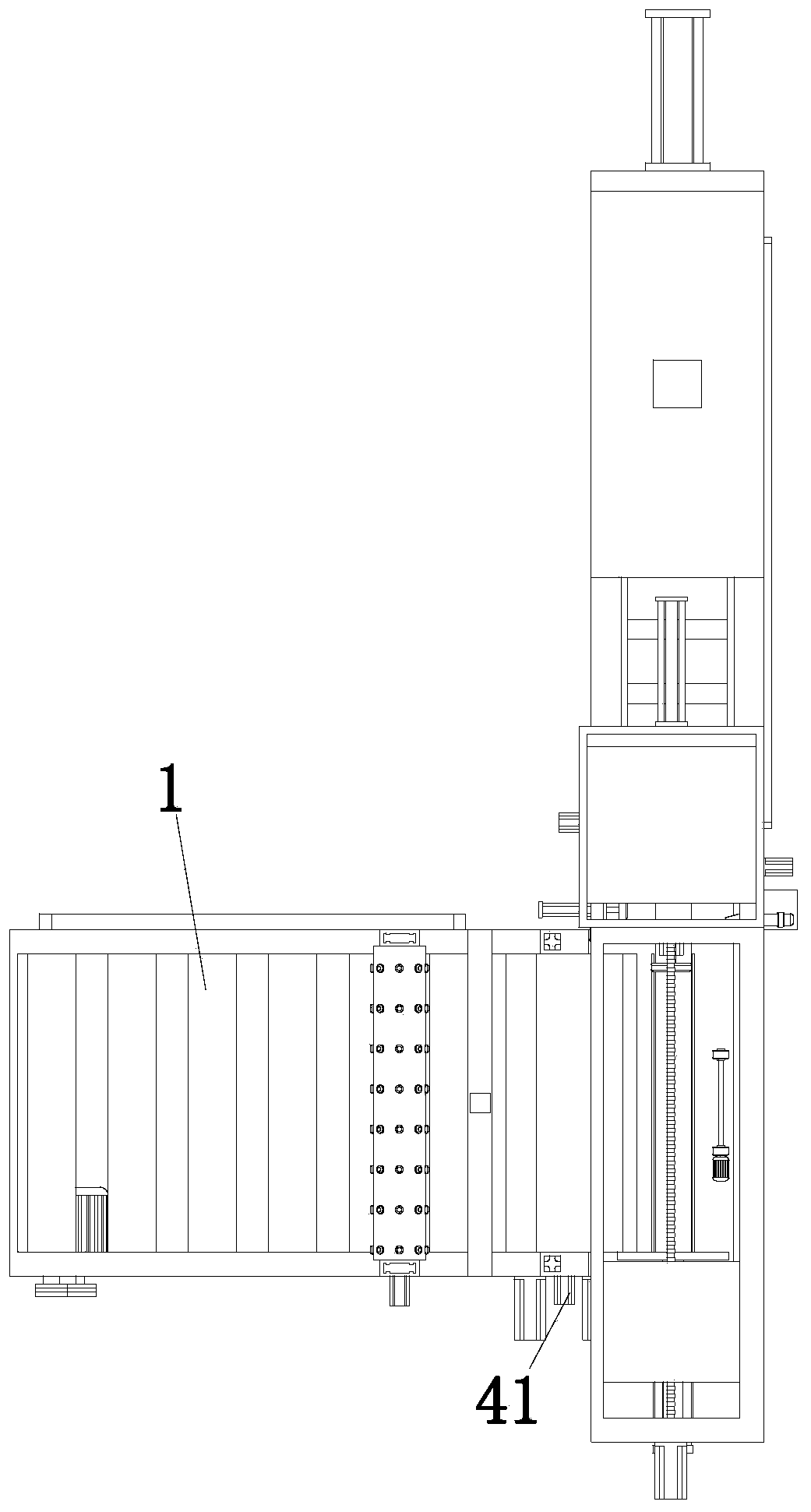

[0037] Combine below Figure 1 to Figure 12 As shown, the embodiment of the present invention provides an integrated machine for automatic rounding, sewing, and leak detection of the inner tank of a solar water heater, including a first conveying assembly 1, an auxiliary conveying mechanism 2, a cutting mechanism 3, a rounding mechanism 4, a sewing mechanism 5, and a blanking mechanism. Mechanism 6 and detection mechanism 7, the first conveying assembly 1 is arranged horizontally, the auxiliary conveying mechanism 2 is arranged on the top of the first conveying assembly 1, and the cutting mechanism 3 is arranged on the top of the first conveying assembly 1 and is located at On the side of the auxiliary conveying mechanism 2, the said rounding mechanism 4 is arranged on the side of the first conveying assembly 1, and said rounding mechanism 4 is arranged correspondingly to the discharge end of the first conveying assembly 1, and said unloading mechanism 6 is arranged on On the ...

Embodiment 2

[0054] Working principle of the present invention: when the present invention is in use, when conveying, the work of the conveying motor 12 drives the first pulley 13 to rotate, and the rotation of the first pulley 13 drives the rotation of the second pulley 16 through the belt 14, and the rotation of the second pulley 16 drives Wherein one conveying roller 15 rotates on the first conveying frame 11, and a conveying roller 15 rotates and drives remaining conveying roller 15 to rotate on the first conveying frame 11 by connecting belt 17, and some conveying rollers 15 rotate and raw material is conveyed forward, to Raw material is processed operation, and in the process that raw material is conveyed forward, the output end of two driving cylinders 24 moves and drives two sliding blocks 25 to move on the sliding groove 231 on two mounting bases 23, and two sliding blocks 25 move will The position of the conveying roller 21 moves to the top of the raw material. At this time, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com