Petroleum drilling and production machine convenient to disassemble and assemble

An oil drilling and machinery technology, applied in earthwork drilling, drilling with vibration, vibration generating device, etc., can solve problems such as transmission dislocation, weakened tool driving force, large drilling inclination, etc., to avoid transmission dislocation and spring distortion. , to promote good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

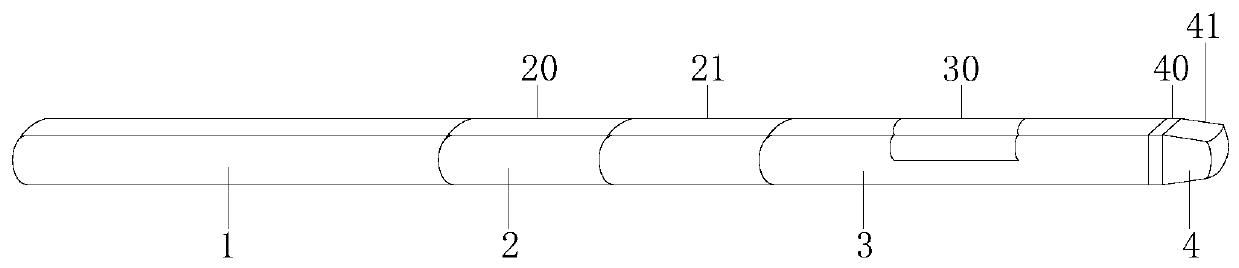

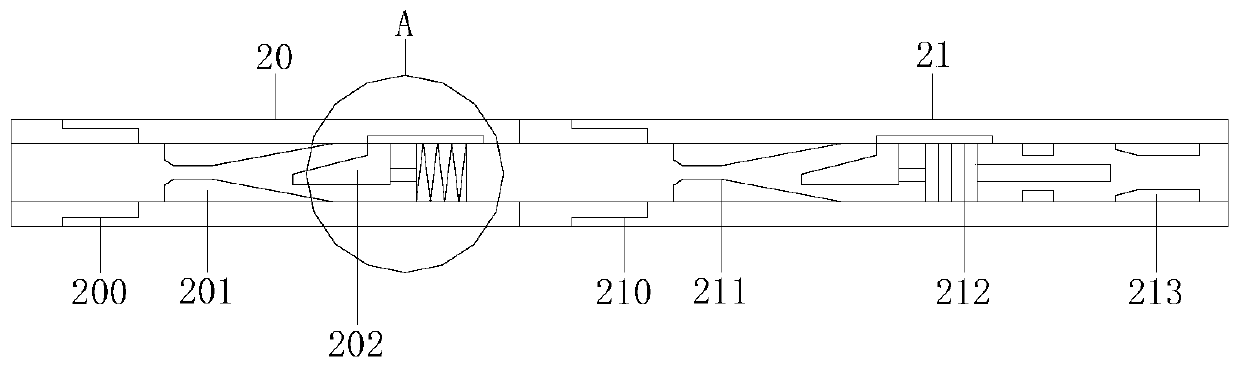

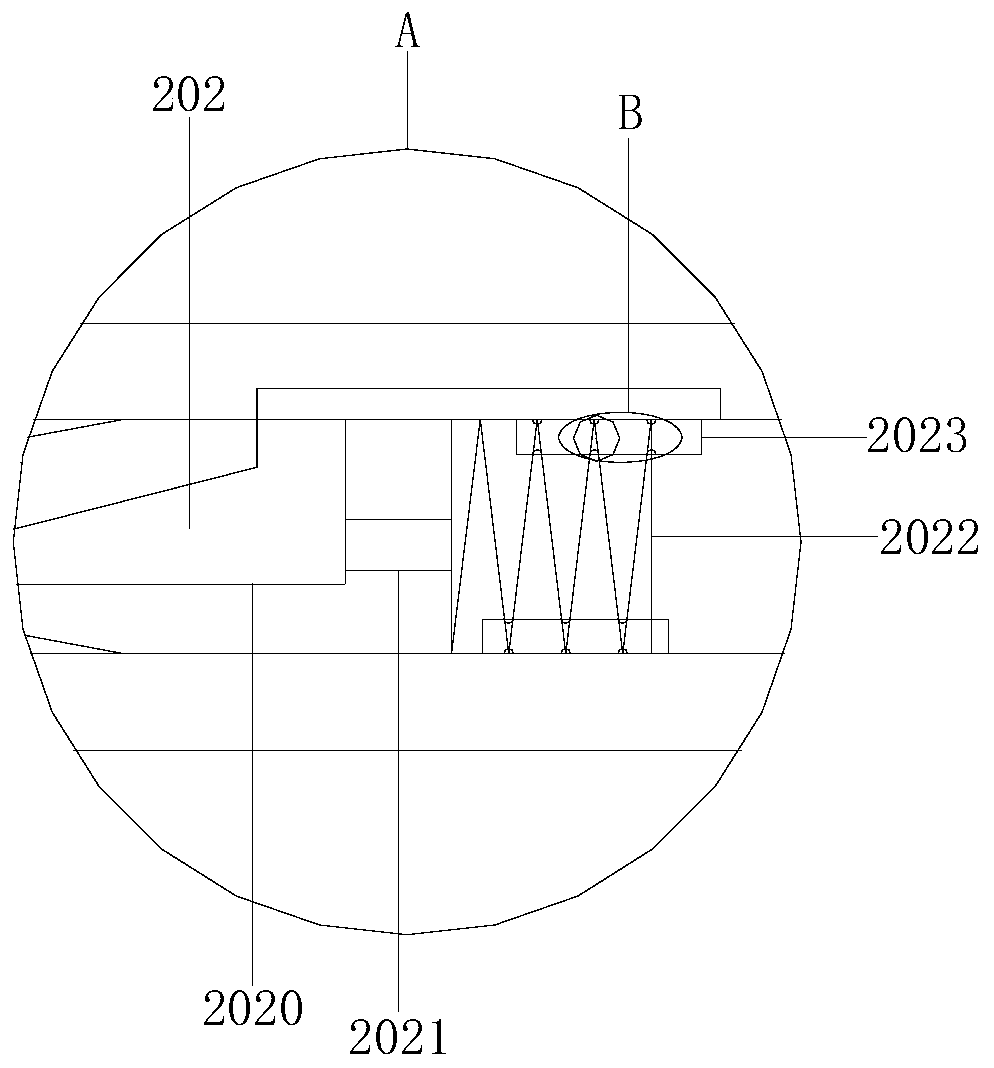

[0024] Example 1 see Figure 1-4 , the present invention provides a technical solution for oil drilling machinery that is easy to disassemble: its structure includes a tail section 1, a middle section 2, an end section 3, and a drill bit 4, and the middle section 2 is assembled and connected with the tail section 1 and the end section 3 , the end section 3 is installed and connected with the drill bit 4, the middle section 2 is composed of a butterfly spring structure 20 and a piston device 21, the butterfly spring structure 20 is assembled and connected with the piston device 21, and the butterfly spring structure 20 is connected with the piston device 21 plays the role of transmission to drive the equipment forward. The end section 3 is equipped with a valve position 30. The drill bit 4 includes a rebound structure 40 and a drill body 41. The rebound structure 40 is connected to the drill body 41. The butterfly spring structure 20 includes a butterfly spring plate 201 and a ...

Embodiment 2

[0026] Example 2 see Figure 5 , the present invention provides a technical solution for oil drilling and production machinery that is easy to disassemble: the rebound structure 40 includes a pop-in structure 400, a rebound frame 401, a rebound shaft 402, and an induction plate 403. The plate 403 is used for real-time distance measurement, the spring-in structure 400 is installed and connected with the rebound frame 401, the rebound frame 401 is connected with the rebound shaft 402, the rebound frame 401, the rebound shaft The body 402 is glued to the induction plate 403, and the elastic arc pad 4020 is glued to the rebound shaft body 402. The pop-in structure 400 includes a frame body 4000, a telescopic elastic plate 4001, and an elastic backing plate 4002. The telescopic elastic plate 4001 can be retracted into the frame body 4000, and has a simple structure and flexible transmission. The frame body 4000 is track-connected with the telescopic spring plate 4001, and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com