Trans/supersonic compressor rotor blades with shock control bulbs

A compressor rotor, supersonic technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., to achieve the effect of improving the stable working range, improving performance, and reducing shock wave intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

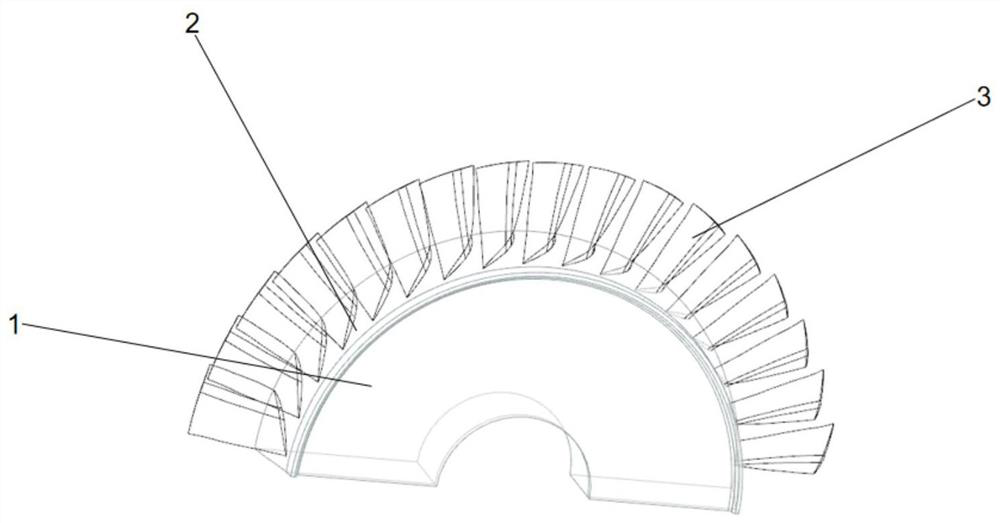

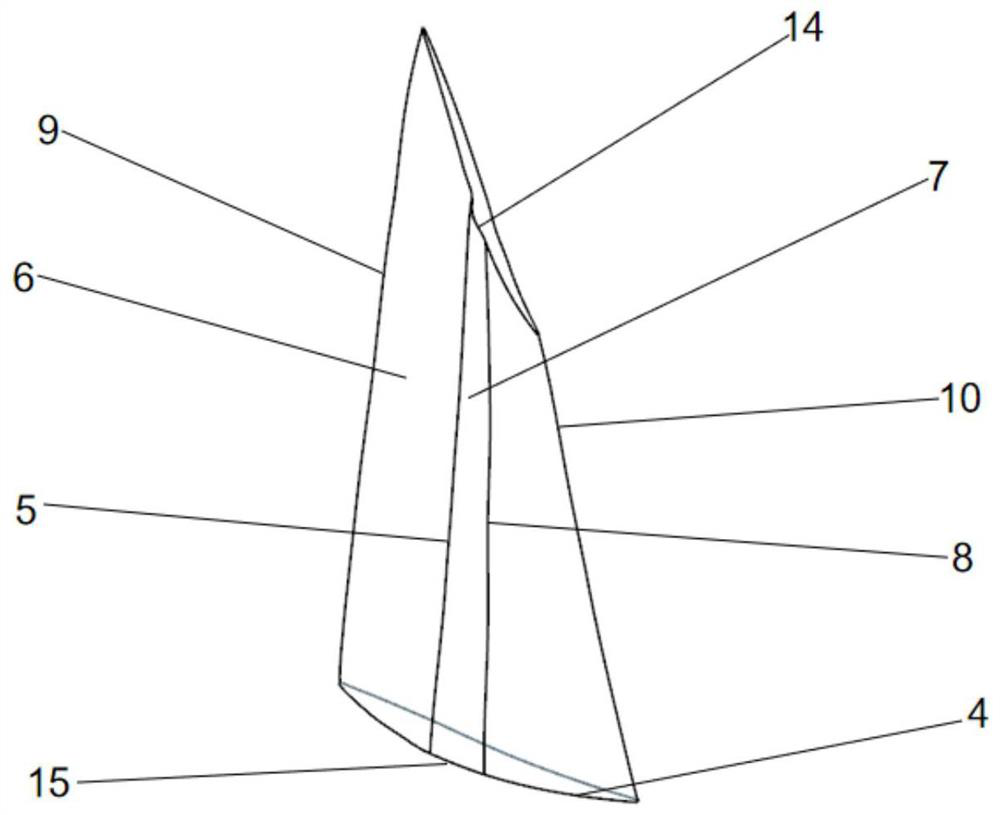

[0077] like Figure 1-5 As shown, the trans / supersonic compressor rotor with continuous shock control bulge provided by the present invention is the trans / supersonic compressor rotor with continuous full-blade height shock control bulge and the continuous partial-blade height shock control Bulky trans / supersonic compressor rotor.

[0078]The trans / supersonic compressor rotor with continuous full-blade high-shock control bulge includes disc 1 and trans / supersonic compressor rotor blade 3 with continuous full-blade high-shock control bulge, and disc 1 is with continuous full-blade The base of the trans / supersonic compressor rotor blade 3 with high shock wave control bulging, the outer edge of the wheel disc 1 is provided with a hub 2, and a plurality of trans / supersonic compressor rotor blades 3 with continuous full-blade hyper shock control bulging along the hub 2 The circumferential intervals are set in sequence.

[0079] The trans / supersonic compressor rotor with continuous...

Embodiment 2

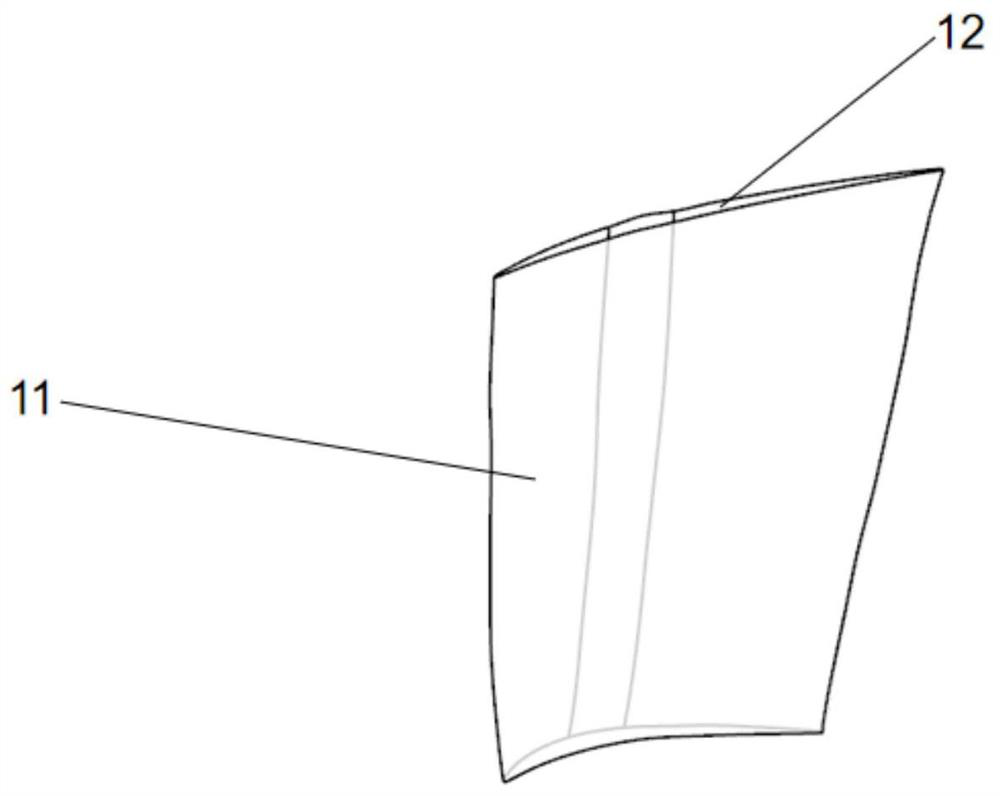

[0084] Different from Embodiment 1, the shock wave control bulge in this embodiment is discontinuously distributed in the blade height direction of the suction surface of the trans / supersonic compressor blade.

[0085] like Figure 6-9 As shown, the trans / supersonic compressor rotor with discontinuous shock wave control bulge provided by the present invention is respectively the trans / supersonic compressor rotor with discontinuous full-blade high shock wave control bulge and the discontinuous part Leaf height shock control for bulging trans / supersonic compressor rotors.

[0086] The trans / supersonic compressor rotor with discontinuous full-blade high-shock control bulge includes a disc 1 and the trans / supersonic compressor rotor blade 16 with discontinuous full-blade high-shock control bulge. Disc 1 is the base of a trans / supersonic compressor rotor blade 16 with discontinuous full-blade hyper-shock wave control bulges. The outer edge of disc 1 is provided with hub 2, and mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com