Device and method for testing plume smoke particles of solid rocket engine

A technology of solid rockets and testing devices, which is applied in the field of aerospace power and can solve problems such as large errors, strong radiation, and high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

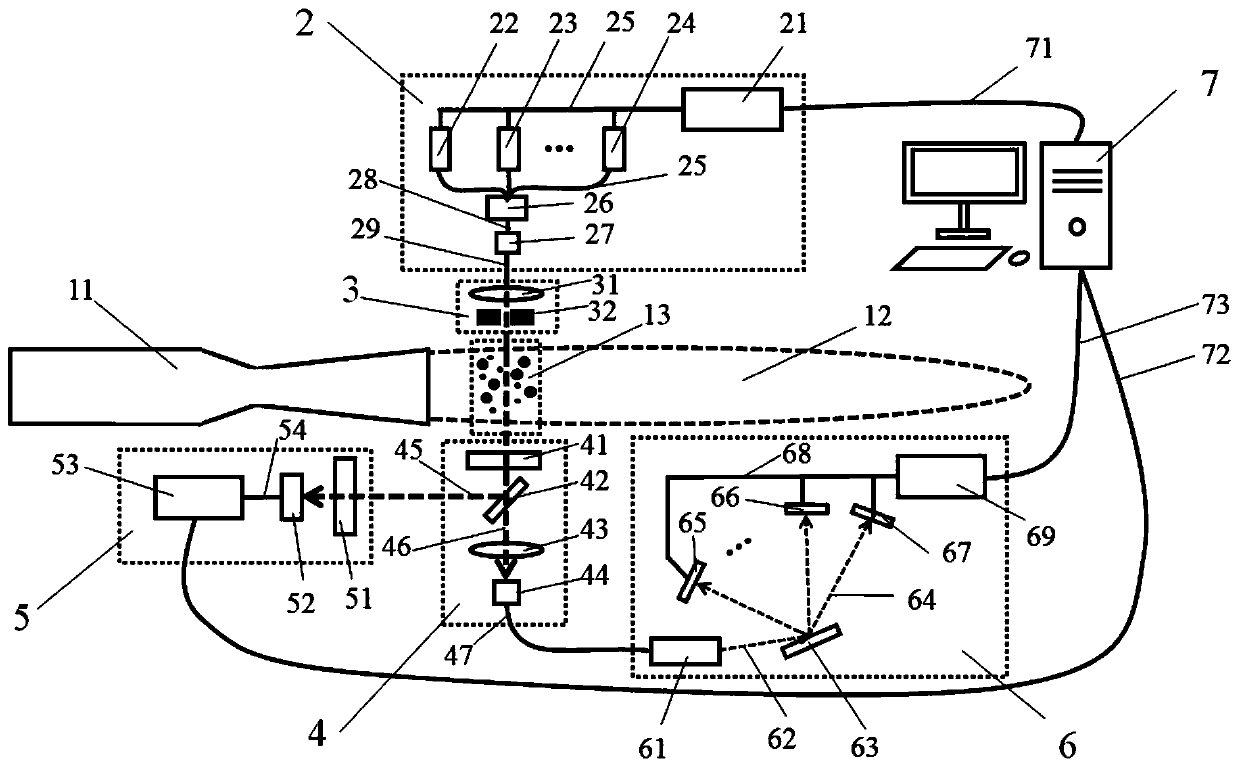

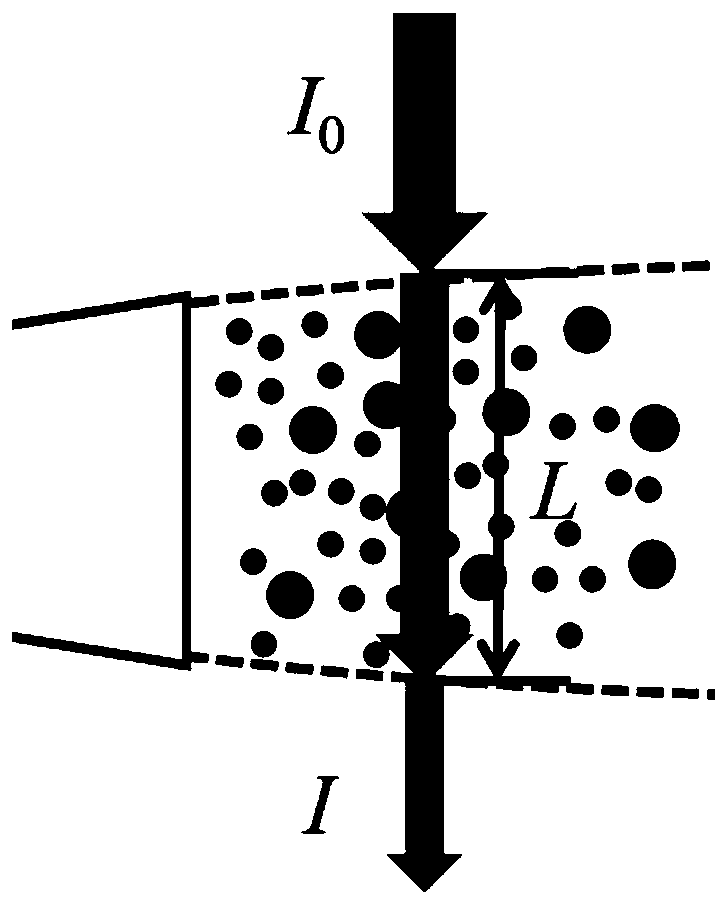

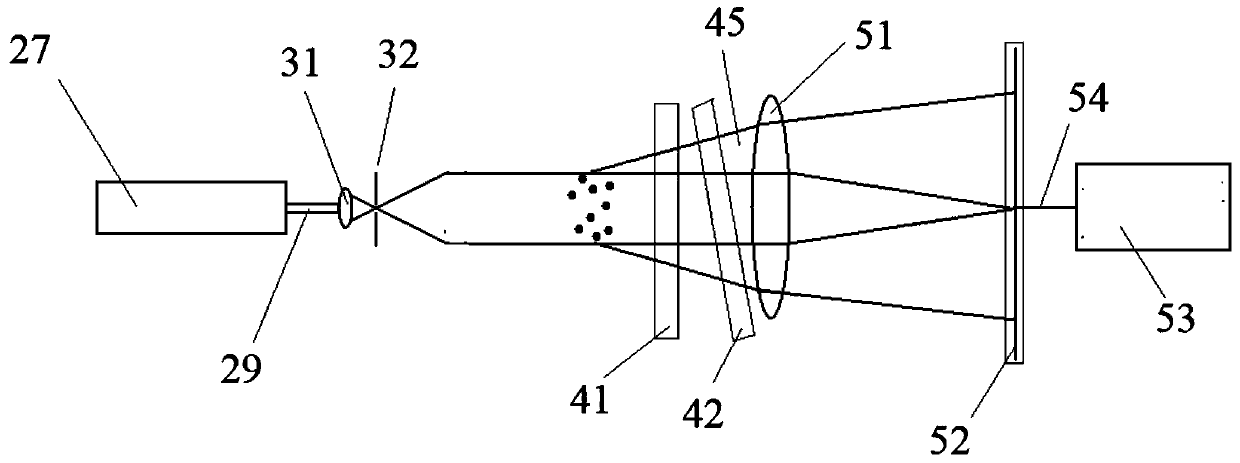

[0056] like figure 1 As shown, the present embodiment provides a solid rocket motor plume smoke particle testing device, which includes a laser light source part 2, a laser modulation part 3, a laser receiving part 4, a laser diffraction detection part 5, a laser attenuation detection part 6, Particle test processing unit 7 , cables 71 , 72 , 73 and optical fibers 28 , 26 , 47 .

[0057] The solid rocket motor plume smoke particle test device is used for testing the solid rocket motor plume smoke particles, and is arranged in the areas on both sides of the exhaust plume 12 of the engine to be tested 11 .

[0058] Wherein, the laser light source part 2 is located on the side of the engine plume 12 and is used to generate incident laser light 20 with different wavelengths.

[0059] The laser modulation unit 3 is located between the engine plume 12 and the laser light source unit 2, and is used to receive the incident laser light 20 emitted by the laser light source unit 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com