Method for reducing complement level and protein precipitation by premixing bovine serum raw materials

A pre-mixed, serum technology, applied in the field of serum, to achieve the effect of reducing complement activity, good correspondence, and sufficient effect and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Thorough premixing process

[0036] Blood was collected from newly born newborn calves by sealing the artery with a six-pack bag. After the blood enters the six-pack bag, it is coagulated, centrifuged at 4000rpm for 30 minutes, and the supernatant is taken by siphon, which is the raw material of bovine serum. Each bag of bovine serum should be marked with the source, blood collection time and operator. After being transported to the production factory through the cold chain, the bovine serum in the blood collection tube (utility model patent has been applied for) is taken out for quality inspection, and the virus (specifically, BVDV, phage, etc.), antibody (specifically, foot-and-mouth disease antibody, IgG) etc. Screening for multiple metrics.

[0037]Qualified raw materials are screened and pre-mixed with serum raw materials of 100 newborn cows, and mixed thoroughly at low temperature (10-15°C, specifically, 12°C) for 2-3 hours (specifically, 2.5 hours) (...

Embodiment 2

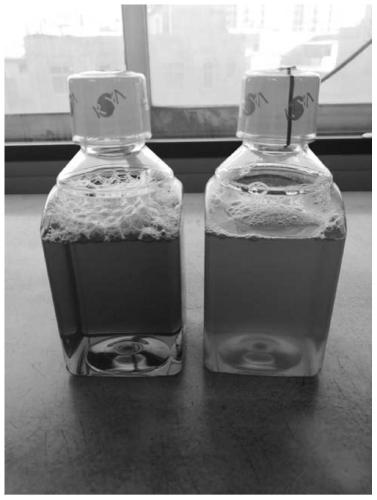

[0039] After the raw serum is fully premixed, the determination of the complement activity of the filtered finished serum and the serum that is not fully premixed is compared.

[0040] 1. Prepare goat antiserum and dilute it to achieve the best sensitization state.

[0041] (1) Rabbit red blood cells (1×10 9 cells / mL) subcutaneously into adult goats, 3ml each time, once a week, for a total of 6 weeks.

[0042] (2) Collect blood from jugular vein of goats at intervals of four days after stopping injection, and separate serum.

[0043] (3) Heat at 56°C for 30 minutes to inactivate the endogenous complement in the antiserum.

[0044] (4) Use GVB2+ (gelatin veronal buffer, gelatin veronal buffer; pH=7.4) solution to make two-fold serial dilutions of the antiserum from 1:100 to 1:1600.

[0045] (5) Take 0.1 mL of the diluent and mix it with the rabbit erythrocyte suspension at a ratio of 1:1, and place the mixture in a water bath at 37°C for 30 minutes. Add 1.3mL of 10-fold dil...

Embodiment 3

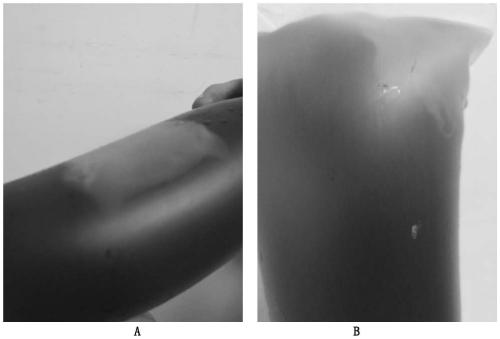

[0063] After the raw serum was premixed for a period of time, protein precipitation occurred. These protein precipitates are blocked with a filter cloth before filtering, and then filtered.

[0064] see figure 1 , This figure reflects the protein precipitation situation, wherein, A picture is the protein precipitation situation after mixing; B picture is the protein precipitation situation after the mixing blocks the precipitation.

[0065] see figure 2 , which shows the filtered finished product after thawing. Among them, the picture on the left is the finished product that is fully pre-mixed at low temperature and filtered, and the picture on the right is the finished product that is filtered after rapid mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com