Method for determining effective monitoring distance of coal mine underground hydraulic fracturing microseism

A technology for hydraulic fracturing and determining methods, applied in seismology, seismic signal processing, geophysical measurement, etc., can solve the problems of small microseismic energy, limited propagation distance, and far away from the source point of the geophone. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0023] The present invention comprises the following steps:

[0024] Step 1. Put the calibration gun and arrange the detector, record the signal, follow the steps below:

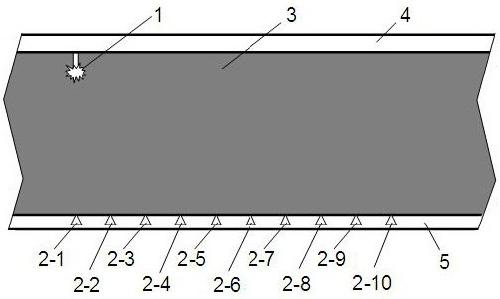

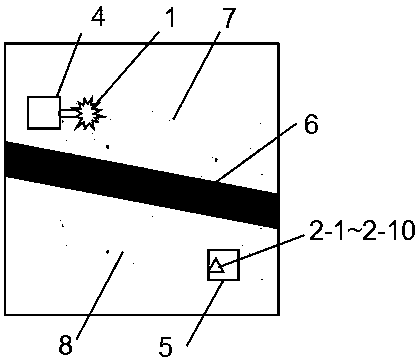

[0025] 11) If figure 1 and figure 2 As shown, the calibration blasting point 1 is selected in the roof rock roadway 4 near the pre-fracturing reservoir 3; the geophones 2-1~2-10 are arranged at equal intervals in the floor rock layer roadway 5, and the distance between each geophone and the blasting point is increase at one time.

[0026] The pre-fracturing reservoir 3 has a coal seam 6, a roof 7 and a floor 8; the roadway is arranged in the rock formation: that is, the roof 7 and the bottom plate 8, and the coal seam roadway is not excavated until the drainage reaches the standard and the gas risk is eliminated.

[0027] 12) Connect the geophone to the microseismic signal acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com