Dynamic virtual system for analyzing and preventing boiler heating surface failure area

A technology of virtual system and heating surface, applied in the field of dynamic virtual system for analysis and prevention of failure area of boiler heating surface, can solve problems such as difficult analysis and traceability, no data analysis, mining and calculation, unpredictable boiler prone parts, etc. The effect of avoiding economic losses, improving management level and technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

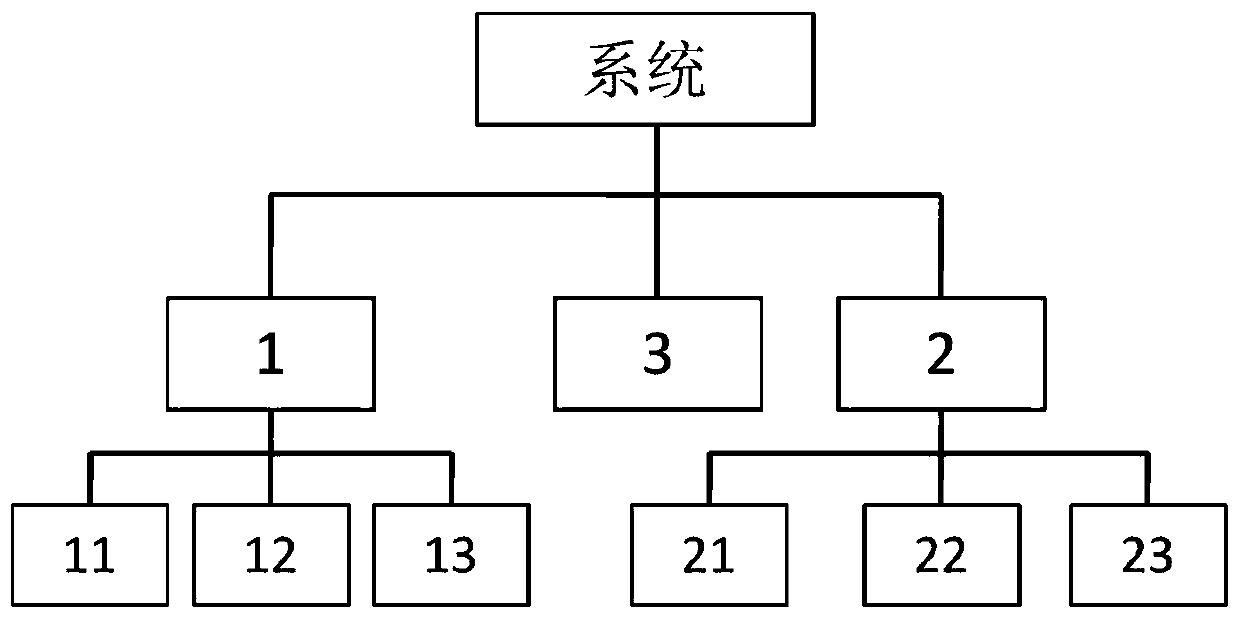

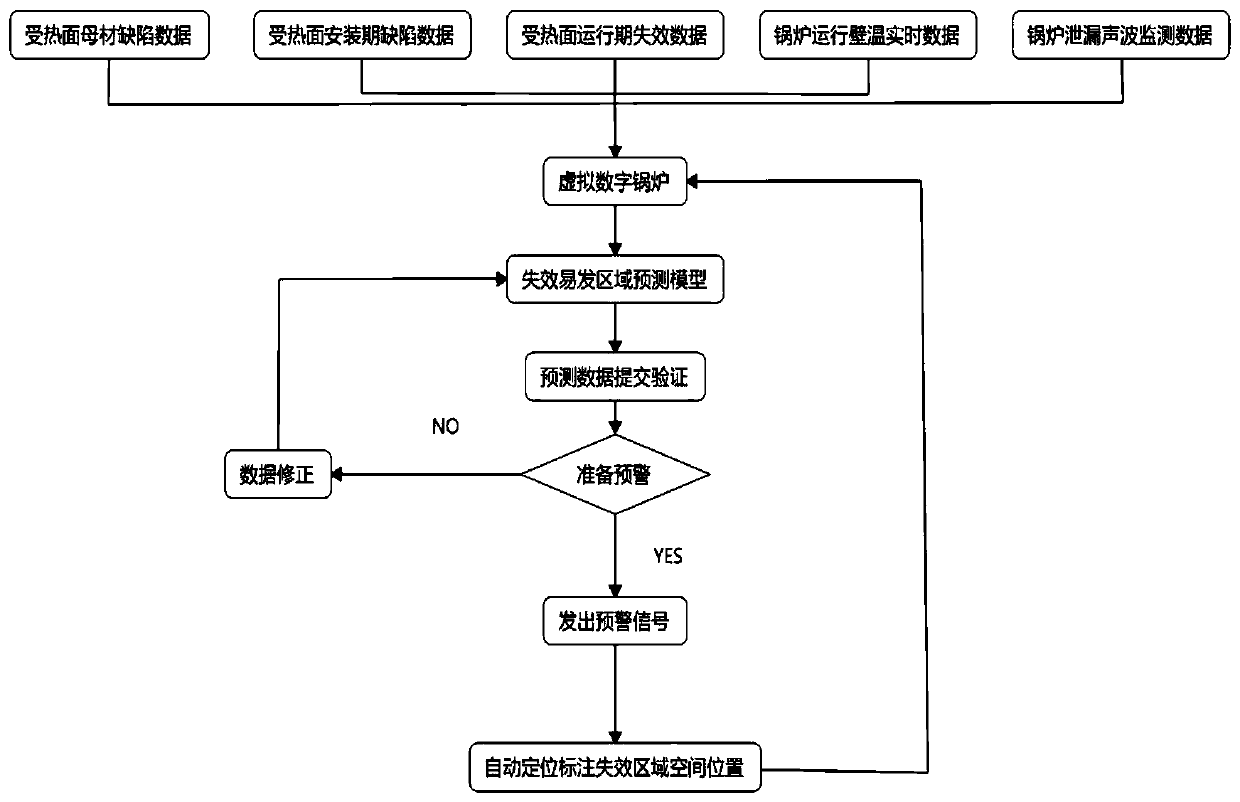

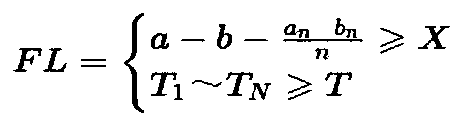

[0034] A dynamic virtual system for analysis and prevention of boiler heating surface failure area, based on the working characteristics of boiler heating surface failure prevention in coal-fired power plants, using computer virtual reality technology to establish a boiler body heating surface failure analysis and prevention and dynamic virtual system, through the computer graphics workstation , carry out computer virtual simulation of the heating surface of the boiler, establish a virtual digital platform for the computer boiler heating surface, collect the real-time monitoring data of the boiler operation status, and combine it with the boiler tube attribute data, failure history data and maintenance data, and at the same time integrate the internal equipment of the power plant The management system and the production process control system are combined to predict and spatially locate the failure-prone areas of the boiler heating surface through data mining analysis, and condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com