Enzyme nutrition powder

A nutrient powder and enzyme technology, applied in food processing, animal husbandry, animal feed and other directions, can solve the problems of reducing the fermentation efficiency of enzyme nutrient powder, reducing the production quality and edible effect of enzyme nutrient powder, etc. High-grade fermentation effect, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

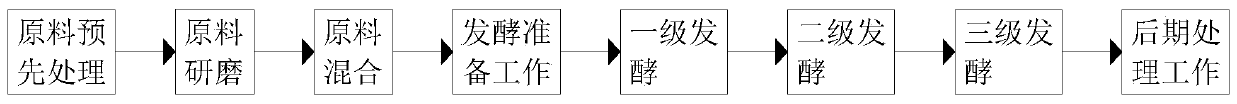

[0026] Please refer to figure 1 ,in figure 1 The process flow chart of the preferred embodiment of the enzyme nutrition powder provided by the present invention. Enzyme nutrition powder, raw materials include rice bran, corn, wheat husk, soybean, black bean, red bean, mung bean, white phoenix bean and enzyme;

[0027] A. Raw material pretreatment: the user pre-grades and screens rice bran, corn, wheat husk, soybean, black bean, red bean, mung bean and white phoenix bean, and then uses cleaning equipment to clean rice bran, corn, wheat husk, soybean, black bean, red bean, Wash mung beans and white phoenix beans with water;

[0028] B. Raw material grinding: The user puts the various raw materials that have been screened and cleaned into the grinder, and then fully grinds the various raw materials and grinds them into powder;

[0029] C. Mixing of raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com