Preparation method and application of resin carbon sphere supported palladium catalyst

A technology of palladium catalyst and resin carbon, which is applied in the field of catalyst preparation and application, to achieve the effects of mild and efficient conversion, good disperse load, and high-efficiency conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

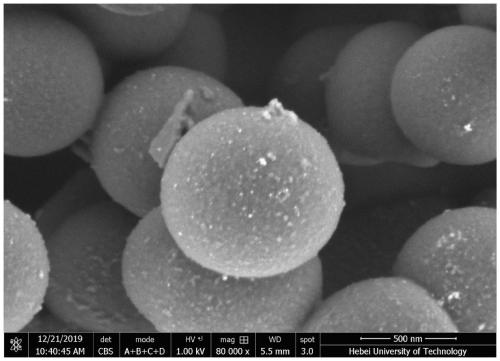

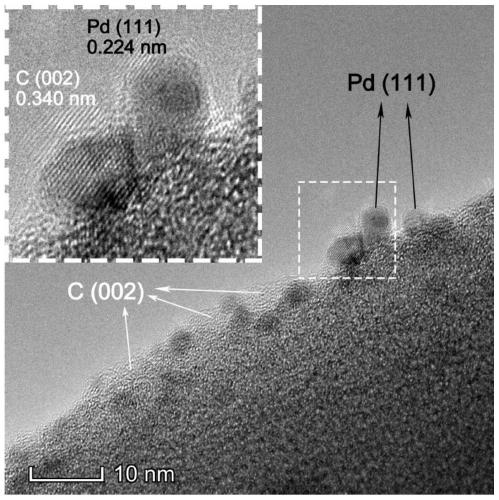

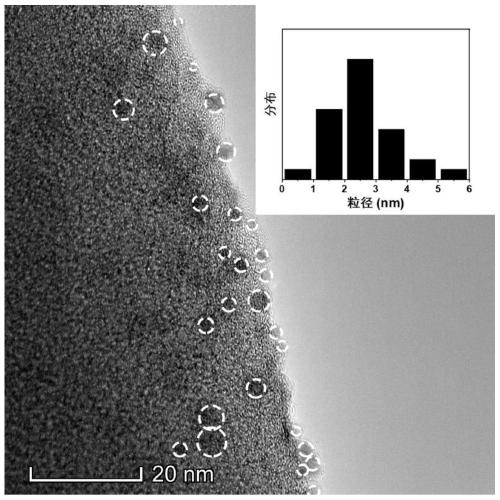

Embodiment 1

[0035] (1) Preparation of the catalyst: Measure 80ml of deionized water and 20ml of absolute ethanol, mix them evenly under magnetic stirring, add 0.23ml of promoter ammonia (25%) to the mixed solution dropwise, and place in a water bath environment of 60°C Stir evenly, then add 2.0g (17.98mmol) resorcinol, stir in a water bath until completely dissolved, then add 1.5ml (37.87mmol) formaldehyde dropwise, stir for 6 hours in a water bath at 60°C, then move to a high-pressure hydrothermal kettle , Hydrothermal reaction in an oven at 80°C for 10h. The solid obtained after the reaction was washed three times with deionized water and three times with ethanol, and finally dried in an oven at 100° C. for 12 hours. Grind the dried solid to powder, and calcined in a tube furnace under a nitrogen atmosphere, first at 1 °C min -1The temperature is raised to 300°C at a rate of 0.5h, and then at 1°C min -1 The temperature was raised to 700°C at a certain rate and kept for 3 hours to obta...

Embodiment 2

[0041] (1) Preparation of the catalyst: Measure 60ml of deionized water and 24ml of absolute ethanol, mix them evenly under magnetic stirring, add 0.1ml of promoter ammonia (25%) to the mixed solution dropwise, and place in a water bath environment at 30°C Stir evenly, then add 0.95g (8.5mmol) resorcinol, stir in a water bath until completely dissolved, then add 1.3ml (32.8mmol) formaldehyde dropwise, stir for 4 hours in a water bath at 30°C, and then move to a high-pressure hydrothermal kettle , hydrothermally reacted in an oven at 100°C for 6h. The solid obtained after the reaction was washed three times with deionized water and three times with ethanol, and finally dried in an oven at 100° C. for 12 hours. Grind the dried solid to powder, and calcined in a tube furnace under nitrogen atmosphere, first at 2 °C min -1 The temperature is raised to 410°C at a rate of 1h, and then at 5°C min -1 The temperature was raised to 800°C at a certain rate and kept for 2 hours to obtai...

Embodiment 3

[0050] (1) Preparation of the catalyst: Measure 42ml of deionized water and 42ml of absolute ethanol, mix evenly under magnetic stirring, add 0.12ml of promoter ammonia (25%) to the mixed solution dropwise, and place the catalyst in a water bath environment at 100°C Stir evenly, then add 1.2g (10.79mmol) resorcinol, stir in a water bath until completely dissolved, then add 2.4ml (60.60mmol) formaldehyde dropwise, stir for 1h in a water bath at 100°C, and then move to a high-pressure hydrothermal kettle , hydrothermally reacted in an oven at 150°C for 5h. The solid obtained after the reaction was washed three times with deionized water and three times with ethanol, and finally dried in an oven at 150° C. for 12 hours. Grind the dried solid to powder, and calcined in a tube furnace under a nitrogen atmosphere, first at 3 °C min -1 The temperature is raised to 450°C at a rate of 1h, and then at 7°C min -1 The temperature was raised to 900°C at a certain rate and kept for 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com