Catalyst for modifying and upgrading bio-oil and preparation method thereof

A bio-oil and catalyst technology, which is applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory catalytic modification and upgrading technology, and achieve stable chemical properties and catalytic activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Configure 10wt% ammonium molybdate solution, and then mix according to the mass ratio of titanium dioxide catalyst:ammonium molybdate solution 1.2:1; after stirring for 10 minutes, a gel is formed, sealed and stored at 50°C for 4-5 hours, and then baked in an oven at 105°C Dry for 4 hours, cool, grind into powder, and then bake in a tube furnace in air atmosphere at 400°C for 6h, then at 550°C for 6h at a temperature rate of 37°C / min to shape and crystallize the catalyst , to get Mo / TiO 2 catalyst. The content of molybdenum is 1% of the total mass of the catalyst.

[0030] In order to verify the results of the synthesized catalyst, TEM, XRD, SEM, NH 3 -TPD and other characterization analysis.

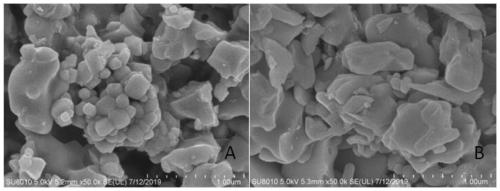

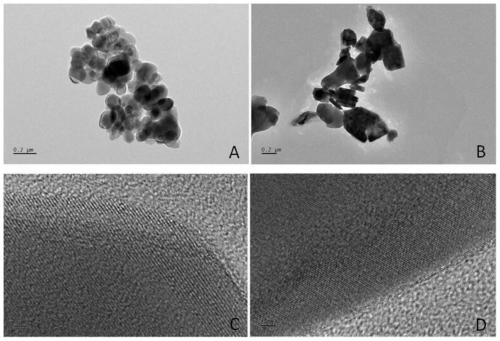

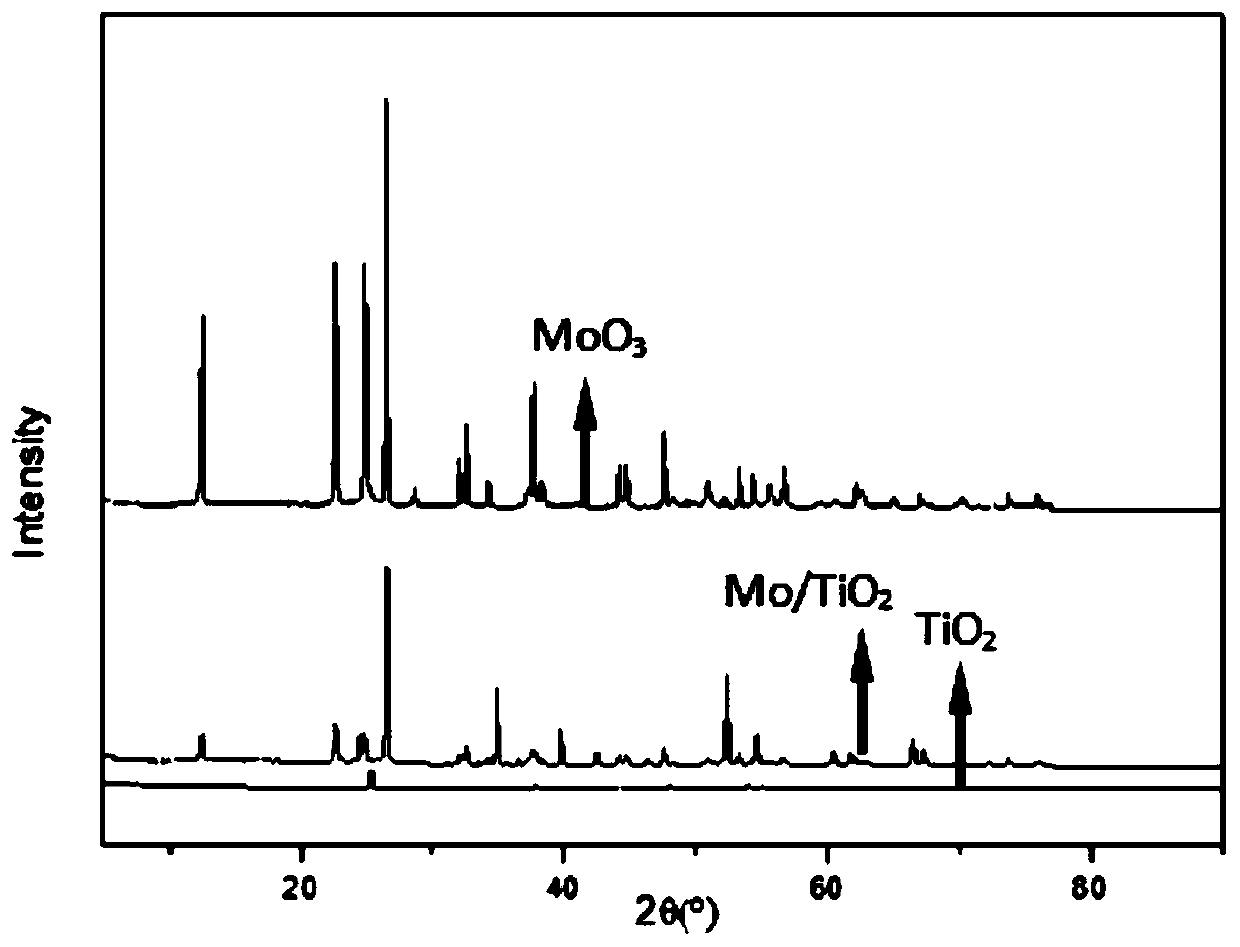

[0031] Such as figure 1 As shown in the SEM image, it was found that the TiO not modified with molybdenum 2 Metal oxides and Mo / TiO 2 Compared with the catalyst, the latter is smoother, indicating that the pore structure of the unmodified catalyst is relatively weak. Althou...

Embodiment 2

[0036] In order to verify the effect of molybdenum / titanium dioxide metal oxide catalyst on hydrodeoxygenation of biomass pyrolysis oil, especially lignin-derived phenolic compounds, catalytic hydrodeoxygenation experiments were carried out in a reactor. The starting material used in the experiments was a model compound of lignin-derived phenols such as phenol. Take by weighing phenol 1g and catalyst (three groups of experiments are set up, one group does not add catalyst, one group adds molybdenum trioxide catalyst, one group adds molybdenum / titania catalyst catalyst) 0.1g (10% of light component quality), 20ml of decalinate was added to the autoclave, purged with nitrogen for 3 times to discharge the air in the autoclave, and then introduced hydrogen to P H2 = 20 Bar (2 standard atmospheres). Heating the reactor (heating rate: 10°C / min) to the specified temperature (330°C) started timing, and the total reaction time was 4 hours. After the reaction is complete, quickly cool...

Embodiment 3

[0039] In order to verify the effect of molybdenum / titanium dioxide metal oxide catalyst on the pyrolysis of lignocellulosic biomass to produce bio-oil, the catalytic pyrolysis experiment of lignocellulosic biomass and waste plastics was carried out using a catalytic fixed-bed reactor combined with a microwave pyrolysis device. The raw material used in the test is a mixture of pine wood and low-density polyethylene (LDPE addition is 25% of pine wood): 50g of pine wood raw material, molybdenum / titanium dioxide metal oxide catalyst consumption is 10% (5g) of biomass raw material, microwave absorber (Activated carbon) 2.5g, the reaction temperature of microwave pyrolysis is 550°C, the time is 8min, and the power is 750W; after the microwave pyrolysis reaction, the pyrolysis gas passes through the catalytic fixed bed for catalytic reforming reaction, and the catalytic reforming reaction temperature is 650 ℃, and the bio-oil was collected after rapid condensation. The results show ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com