A medium-low temperature coal tar hydrodeoxygenation catalyst and its preparation and application

A low-temperature coal tar and deoxidation catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of inability to efficiently remove oxygen and break C-O bonds The weak ability and other problems, to achieve the effect of short production cycle, promote adsorption, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Under constant temperature conditions of 32°C, dissolve 3.2g of F127 and 0.4g of citric acid in 20ml of absolute ethanol, add 1.6g of 37wt% concentrated hydrochloric acid, seal with PE film and keep stirring for 30min.

[0036] Then add 3.26g of aluminum isopropoxide, 0.2050g of cerium nitrate, 0.4729g of zirconium nitrate and 0.2688g of nickel nitrate under rapid stirring, seal with PE film and keep stirring for 24h to form a sol.

[0037] The formed sol was transferred to a watch glass and kept in an oven at 45°C for 48h and at 100°C for 24h to form a light green film-like sample.

[0038] The sample was placed in a muffle furnace, the heating rate was controlled to be 1 °C / min, and the temperature was raised to 400 °C for 4 h for calcination.

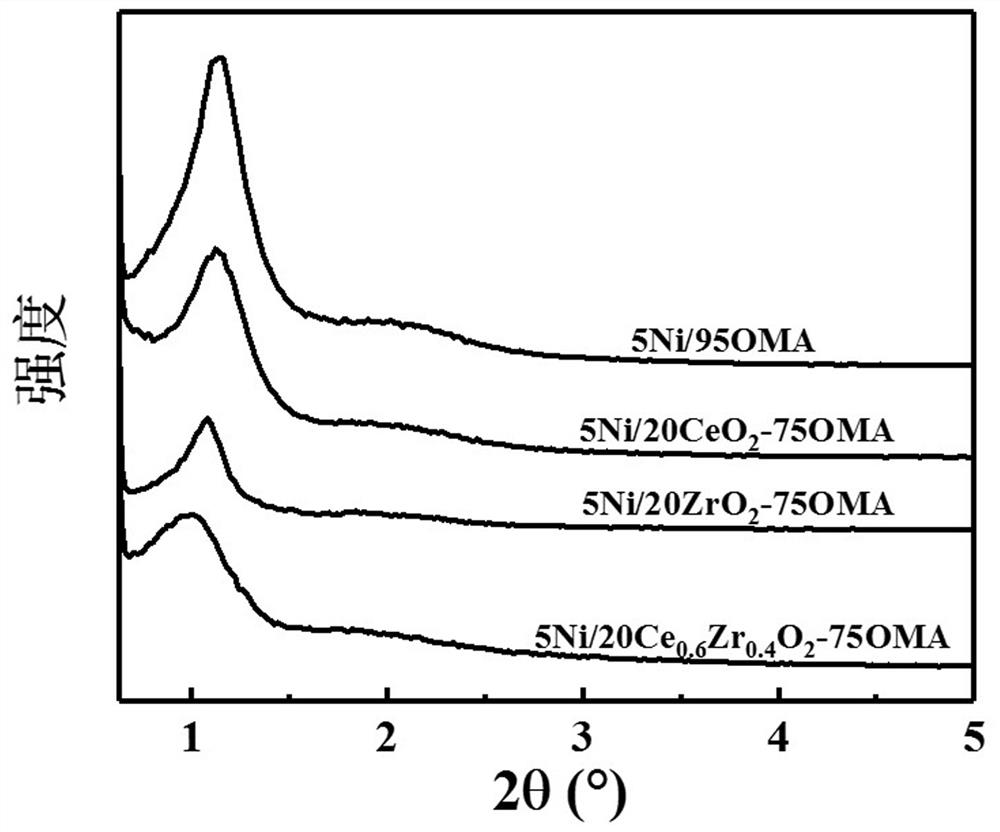

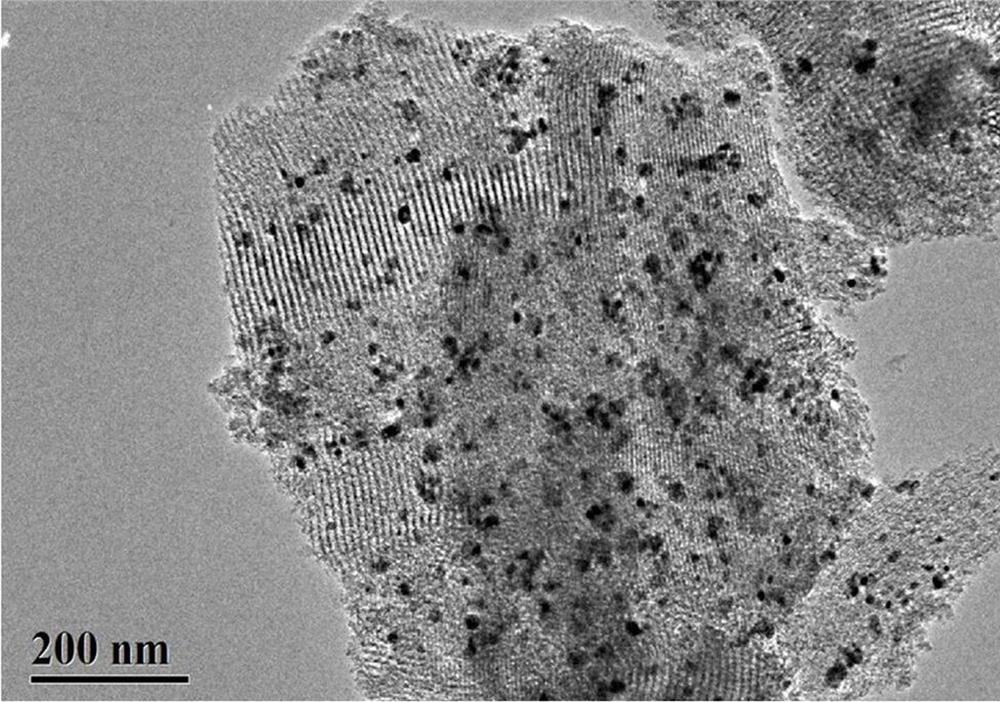

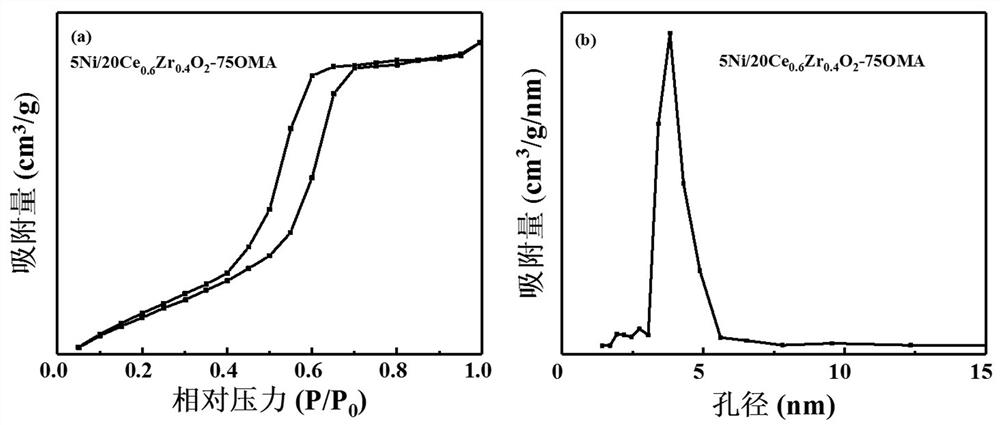

[0039] After calcination, the sample was placed in a vacuum tube furnace, heated and reduced in a hydrogen atmosphere, controlled at a heating rate of 2°C / min, and kept at 500°C for 4 hours, and finally prepared ordered mesopo...

Embodiment 2

[0041]Under constant temperature conditions of 32°C, dissolve 3.2g of F127 and 0.4g of citric acid in 20ml of absolute ethanol, add 1.6g of 37wt% concentrated hydrochloric acid, seal with PE film and keep stirring for 30min.

[0042] Then add 3.26g aluminum isopropoxide, 0.2640g cerium nitrate, 0.3915g zirconium nitrate and 0.2688g nickel nitrate under rapid stirring, seal with PE film and continue stirring for 24h to form a sol.

[0043] The formed sol was transferred to a watch glass and kept in an oven at 45°C for 48h and at 100°C for 24h to form a light green film-like sample.

[0044] The sample was placed in a muffle furnace, the heating rate was controlled to be 1 °C / min, and the temperature was raised to 400 °C for 4 h for calcination.

[0045] After calcination, the sample was placed in a vacuum tube furnace, heated and reduced in a hydrogen atmosphere, controlled at a heating rate of 2°C / min, and kept at 500°C for 4 hours, and finally prepared ordered mesoporous 5Ni / ...

Embodiment 3

[0047] Under constant temperature conditions of 32°C, dissolve 3.2g of F127 and 0.4g of citric acid in 20ml of absolute ethanol, add 1.6g of 37wt% concentrated hydrochloric acid, seal with PE film and keep stirring for 30min.

[0048] Then add 3.26g of aluminum isopropoxide, 0.3190g of cerium nitrate, 0.3154g of zirconium nitrate and 0.2688g of nickel nitrate under rapid stirring, seal with PE film and keep stirring for 24h to form a sol.

[0049] The formed sol was transferred to a watch glass and kept in an oven at 45°C for 48h and at 100°C for 24h to form a light green film-like sample.

[0050] The sample was placed in a muffle furnace, the heating rate was controlled to be 1 °C / min, and the temperature was raised to 400 °C for 4 h for calcination.

[0051] After calcination, the sample was placed in a vacuum tube furnace, heated and reduced in a hydrogen atmosphere, controlled at a heating rate of 2°C / min, and kept at 500°C for 4 hours, and finally prepared ordered mesopo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com