Crystallizer copper pipe inner cavity machine tool

A mold copper tube and inner cavity processing technology, which is applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of long time-consuming mandrel mold manufacturing, low machine rigidity and high precision, and shorten the design cycle. , The effect of improving dimensional accuracy and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

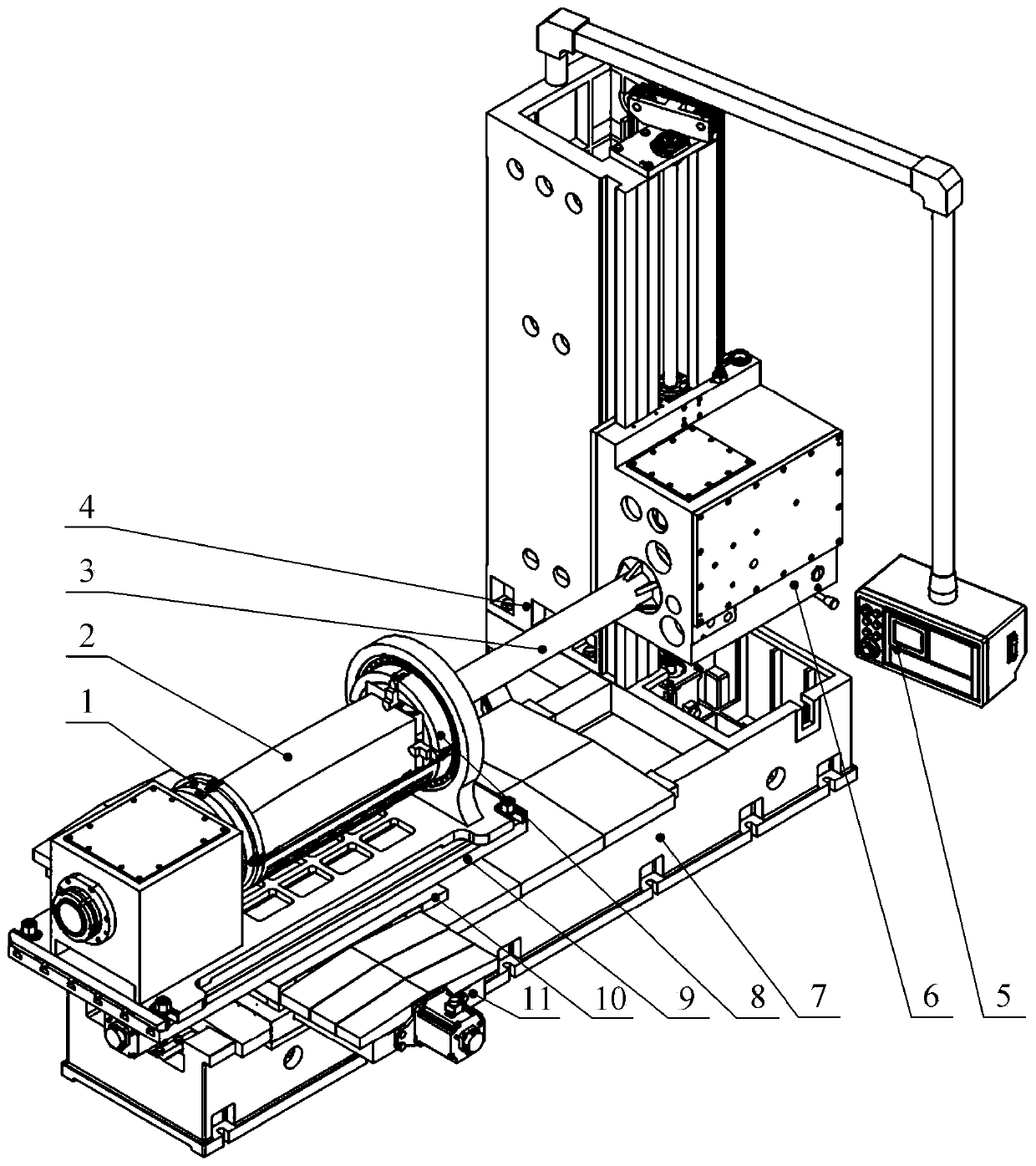

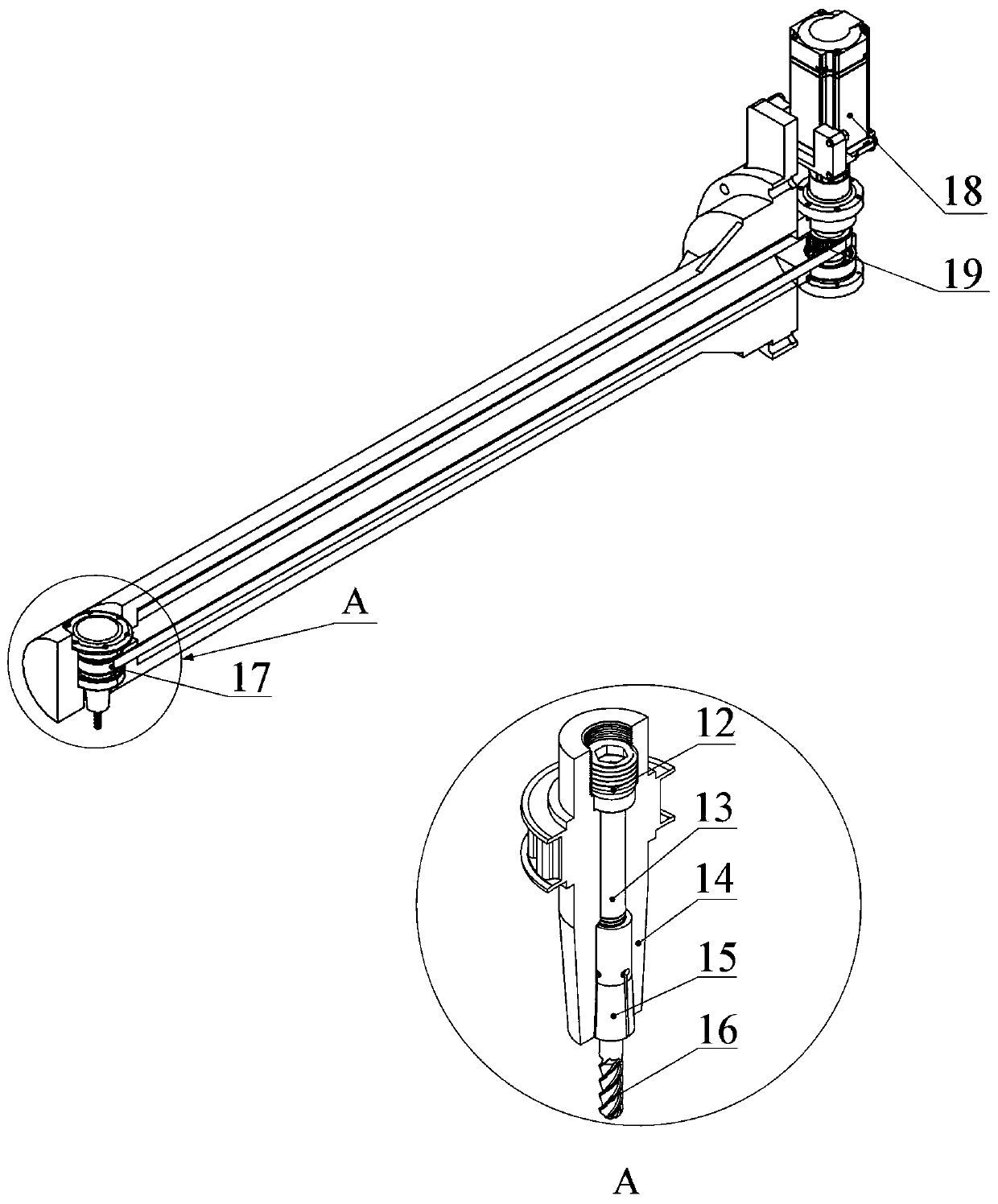

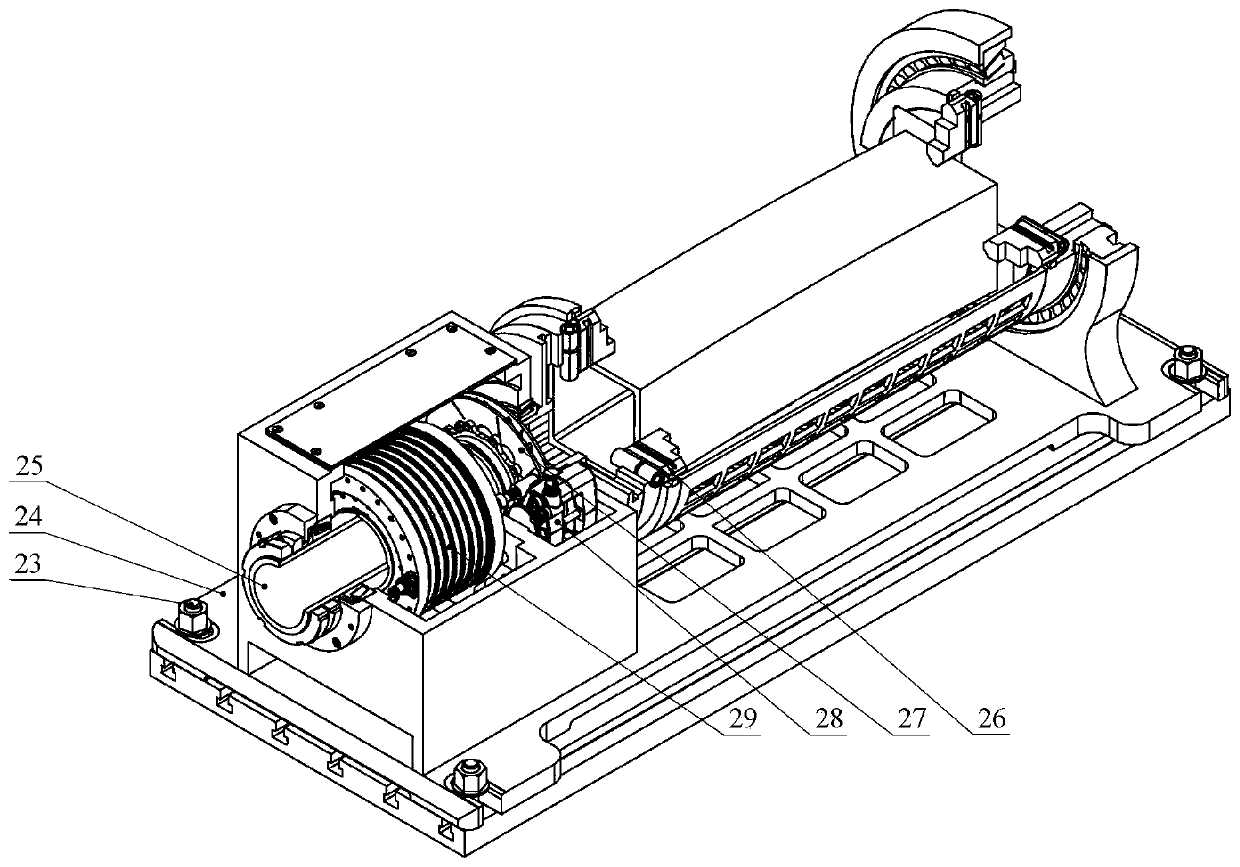

[0034] Such as Figure 1 to Figure 6As shown, the present invention provides a kind of crystallizer copper tube inner cavity processing machine tool, comprising: bed 7, described bed 7 is placed on the horizontal working surface, and described bed 7 upper end is provided with longitudinal slideway, and the A sliding seat 11 is provided on the longitudinal slideway, so that the sliding seat 11 can move longitudinally under the drive of the longitudinal feed mechanism, and the sliding seat 11 cooperates with the bed 7 to form a moving pair; the sliding seat 11 is provided with A horizontal slideway, and the upper slideway is provided with an upper slide 10, so that the upper slide 10 can move laterally under the drive of the transverse feed mechanism, and the upper slide and the lower slide cooperate to form a moving pair; Above-mentioned upper sliding seat 10 is provided with workbench 9, and described workbench 9 is provided with indexing system, and described indexing system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com