Garbage collecting device

A garbage collection and garbage technology, applied in garbage collection, trash cans, waste collection and transfer, etc., can solve problems such as affecting the beauty of the environment and the health of tourists, increasing the load of sewage treatment plants, increasing treatment costs, etc., and reducing environmental protection projects. Investment, reducing water pollution, reducing the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

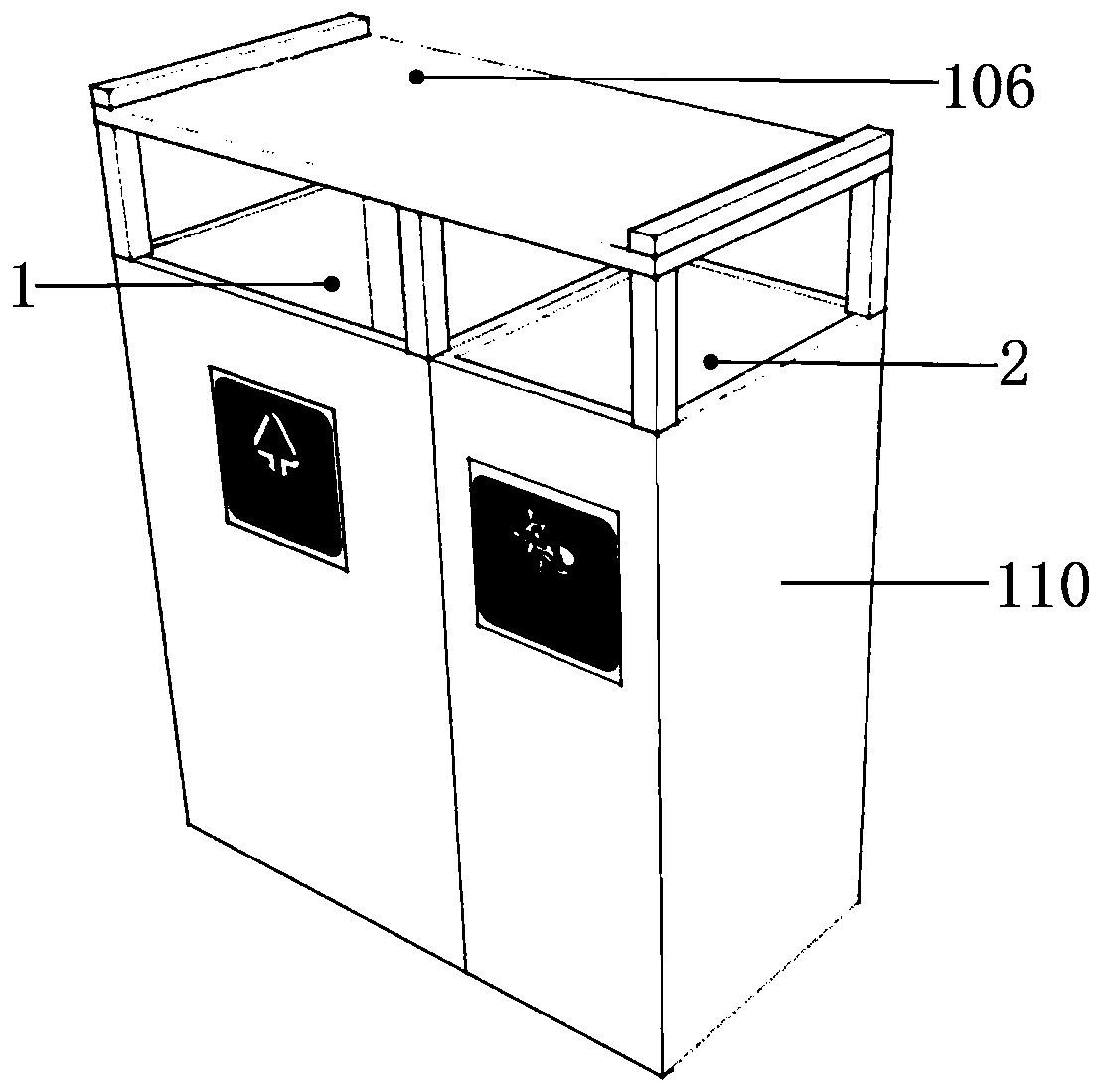

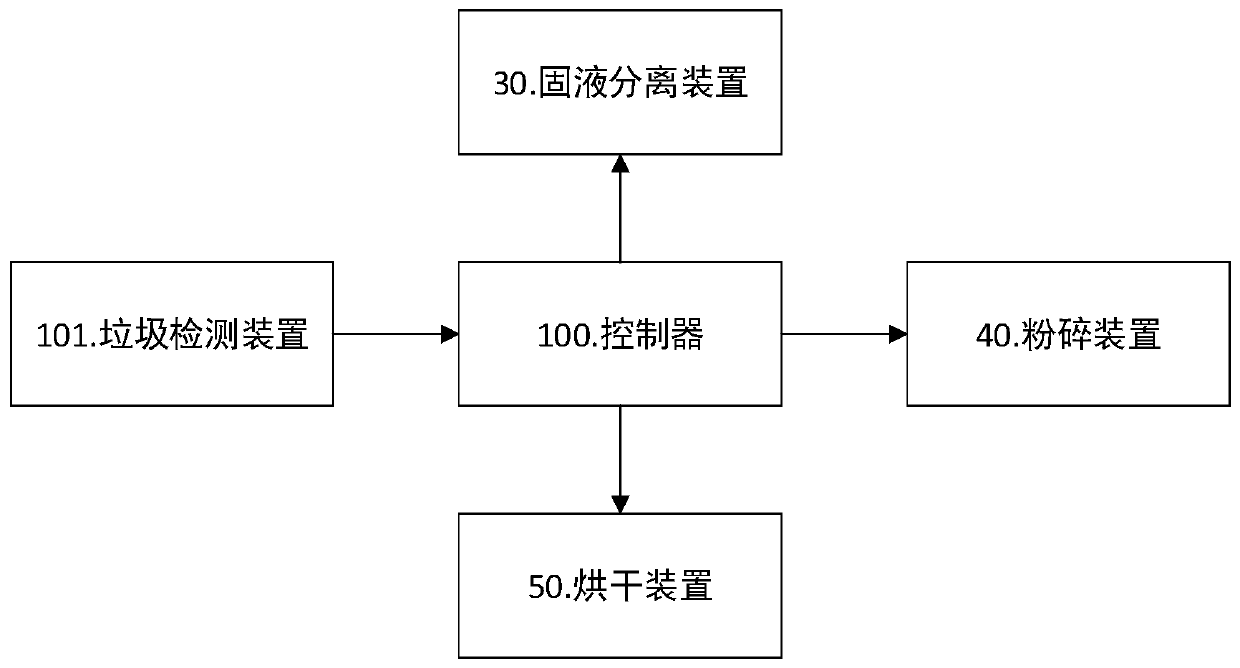

[0044] see Figure 1-Figure 5 , the present embodiment provides an outdoor garbage collection device, including: a dry garbage collection device 1 and a wet garbage collection device 2, and the wet garbage collection device 2 includes: a solid-liquid separation chamber 3, a crushing chamber 4, a drying chamber chamber 5, liquid storage chamber 6 and residue storage chamber 7; the solid-liquid separation chamber 3 is provided with a solid-liquid separation device 30, the crushing chamber 4 is provided with a crushing device 40, and the drying chamber 5 is provided with a drying device 50; after the wet garbage is put into the wet garbage collection device 2, the solid-liquid separation is realized by the solid-liquid separation device 30 in the solid-liquid separation chamber 3, and the liquid enters the liquid storage The chamber 6 is stored, the solid enters the crushing chamber 3 and is crushed by the crushing device 40, and the crushed residue enters the drying chamber 5 an...

specific Embodiment approach

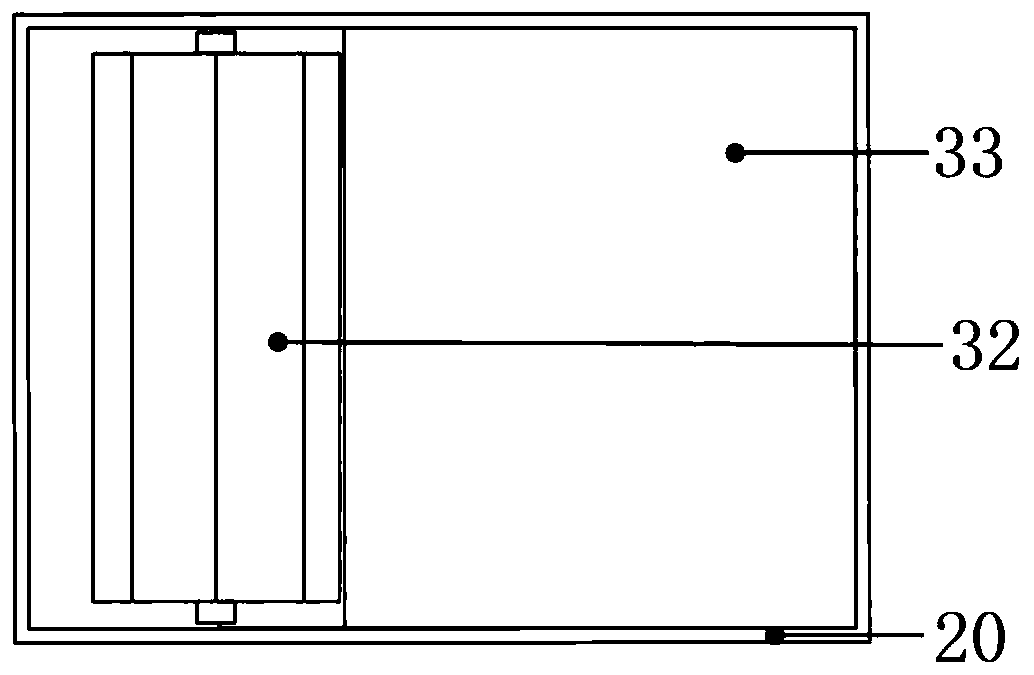

[0048] The outdoor garbage collection device is a box body 110 as a whole, and the dry garbage collection device 1 is a dry garbage can for storing dry garbage. The dry garbage can 1 is basically the same as the traditional method but the volume is increased to meet the needs of use. The wet garbage collection device 2 includes a bucket body 20 with an open end, and the dry garbage collection device 1 and the wet garbage collection device 2 are arranged side by side in the box body 110 . The solid-liquid separation chamber 3 is located in the barrel body 20, and the crushing chamber 4, the drying chamber 5, and the residue storage chamber 7 are sequentially located below the solid-liquid separation chamber 3; the solid-liquid separation device 30 includes a first mill Pressing device 31, the first rolling device 31 includes a roller 32, and the roller 32 is fixed on the inner side wall of the barrel body 20 through a central axis, as image 3 shown. A baffle 33 is also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com