A kind of acrylic acid epoxy core-shell emulsion and preparation method thereof

A technology of acrylic and epoxy core, applied in the field of acrylic epoxy core-shell emulsion and its preparation, to achieve the effects of improving compactness, improving film forming compactness, and perfecting the raw material system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

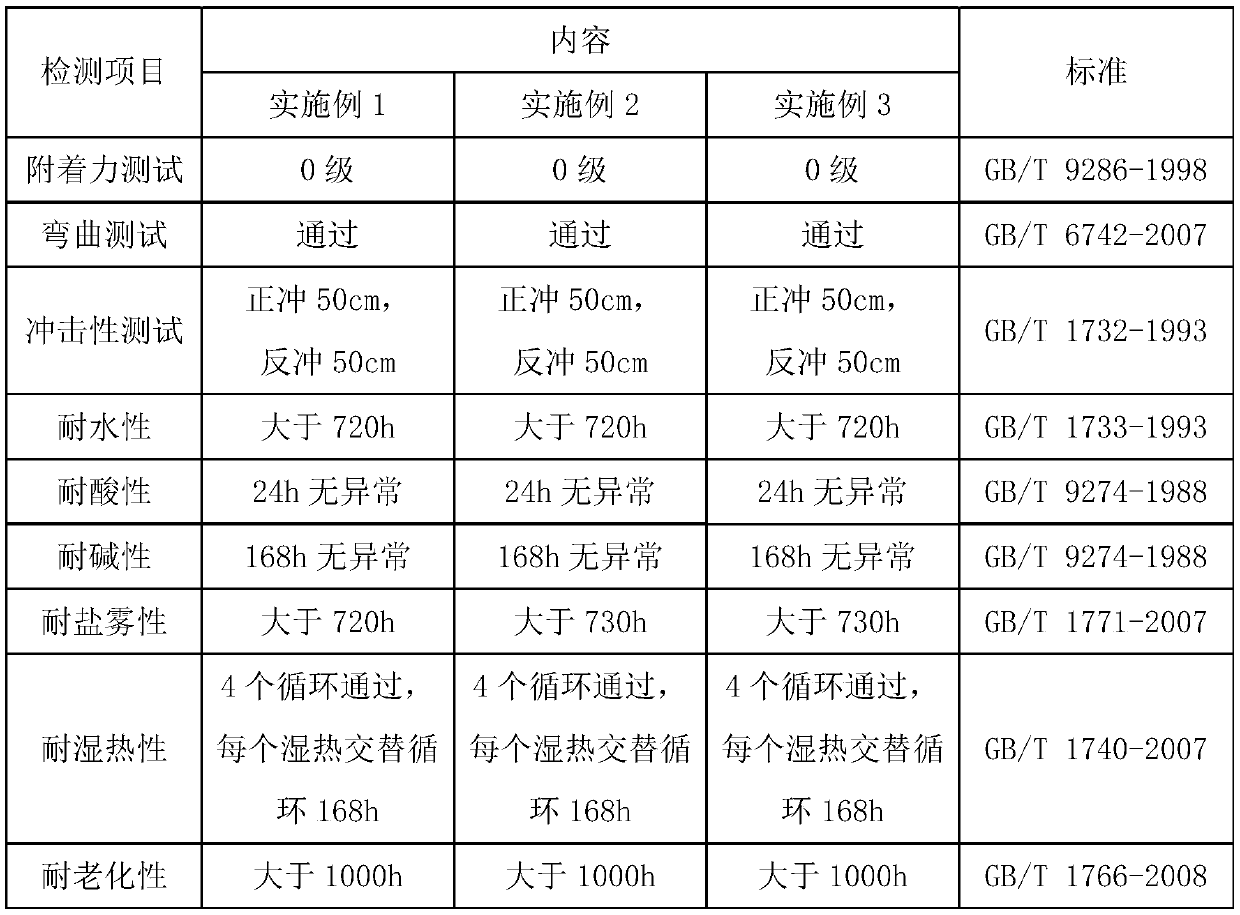

Examples

preparation example Construction

[0036] In addition, the present invention also provides a method for preparing the acrylic epoxy core-shell emulsion described in any one of the above, which specifically includes the following steps in terms of parts by mass,

[0037] 1) Pre-emulsification: Under normal temperature and pressure, mix 2-10 parts of anionic emulsifier, 20-30 parts of water, 5-10 parts of epoxy resin and 10-40 parts of butyl acrylate in a pre-emulsification tank, fully stir and dissolve , and sequentially add 20-40 parts of styrene, 5-20 parts of butyl acrylate, and 0.5-3 parts of acrylic acid;

[0038]2) Polymerization: add 90-210 parts of water and 1-2 parts of anionic emulsifier to the bottom of the reaction kettle, raise the temperature to 80-90°C, stir for 20-40 minutes, add dropwise the pre-emulsion obtained in step 1) and 0.1-0.5 part of initiator is used for chemical reaction, the dropping time is 150-300 minutes, the reaction temperature is 80-90°C, and the reaction time is 170-340 minut...

Embodiment 1

[0046] A preparation method of an acrylic epoxy core-shell emulsion, calculated in parts by mass, including 150 parts of water, 30 parts of styrene, 30 parts of methyl methacrylate, 20 parts of isooctyl acrylate, 20 parts of butyl acrylate, acrylic acid 0.5 parts, 0.5 parts of methacrylic acid, 5 parts of epoxy resin, 5 parts of anionic emulsifier, 1 part of crosslinking monomer, 5 parts of water-based epoxy curing agent, 0.5 parts of initiator, 0.1 part of oxidizing agent, and 0.1 part of reducing agent;

[0047] Wherein, the epoxy resin is E44;

[0048] Described anionic emulsifier is sodium lauryl sulfate;

[0049] The crosslinking monomer is trimethylolpropane trimethacrylate;

[0050] The water-based epoxy curing agent is an amine curing agent;

[0051] Described initiator is sodium persulfate;

[0052] The oxidant is an organic peroxide;

[0053] Described reducing agent is sodium binitrite;

[0054] The preparation method of this emulsion specifically comprises the...

Embodiment 2

[0064] A preparation method of an acrylic epoxy core-shell emulsion, calculated in parts by mass, including 200 parts of water, 45 parts of styrene, 45 parts of methyl methacrylate, 50 parts of isooctyl acrylate, 50 parts of butyl acrylate, acrylic acid 3 parts, 3 parts of methacrylic acid, 7 parts of epoxy resin, 10 parts of anionic emulsifier, 3 parts of crosslinking monomer, 10 parts of water-based epoxy curing agent, 1 part of initiator, 0.3 part of oxidizing agent, and 0.3 part of reducing agent;

[0065] Wherein, described epoxy resin is that E44, E35 are mixed according to 1:1;

[0066] Described anionic emulsifier is sodium dodecylbenzenesulfonate;

[0067] The cross-linking monomer is trimethylolpropane acrylate, tripropylene glycol diacrylate mixed according to 1:1;

[0068] The water-based epoxy curing agent is an alcohol curing agent;

[0069] Described initiator is ammonium persulfate;

[0070] The oxidant is an organic peroxide;

[0071] The reducing agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com