Drill bit device integrating underground water rapid getting and in-situ injection repairing functions

An in-situ injection and groundwater technology, applied in the field of environmental remediation, can solve problems such as inability to obtain representative groundwater samples, inability to effectively remediate pollutants, and difficult construction of monitoring wells, so as to avoid further diffusion, improve remediation efficiency, and simplify tools effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

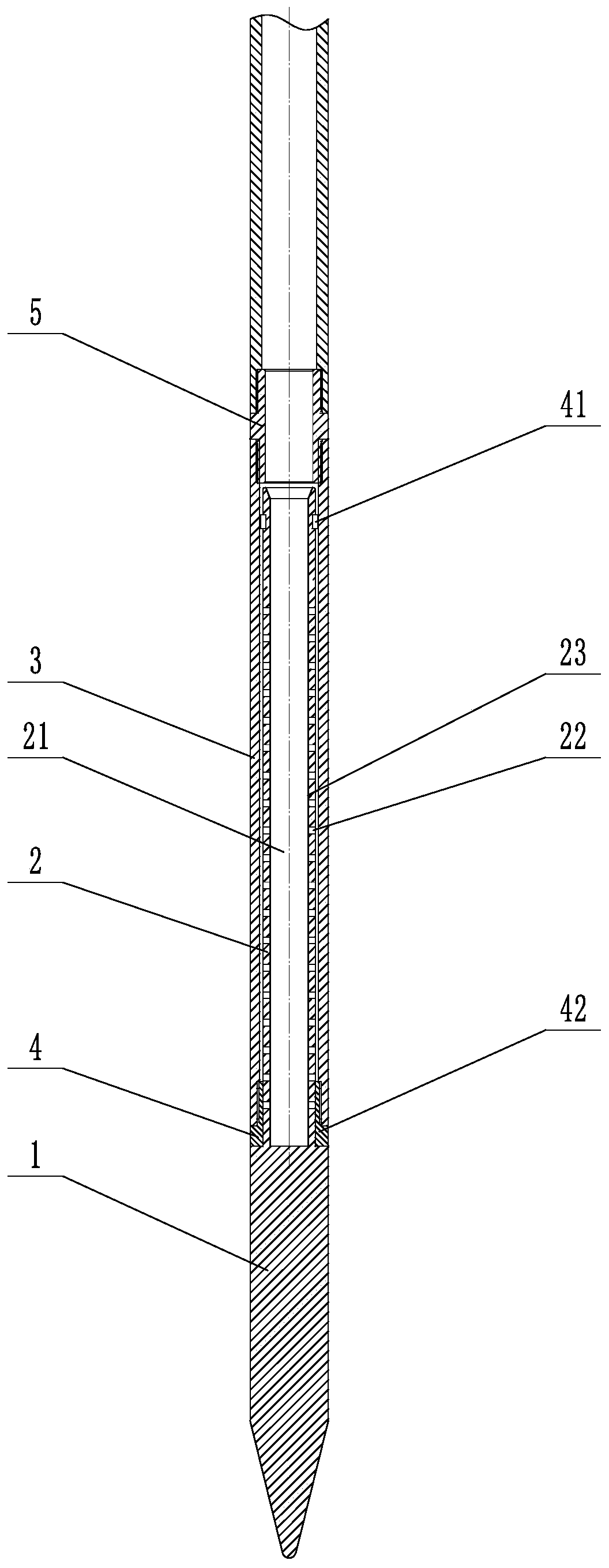

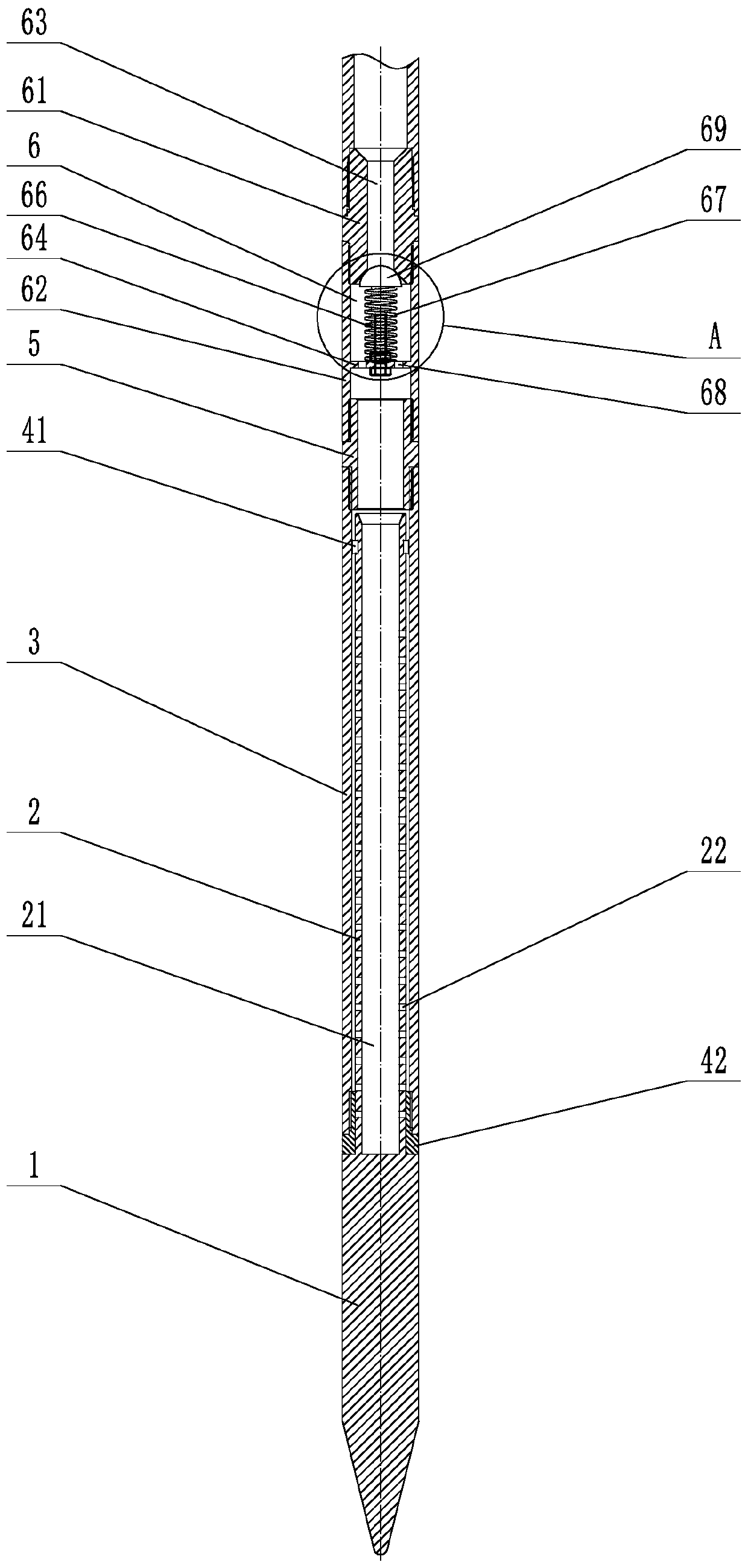

[0030]A certain chemical plant is suspected of sneaking or leaking drainage during the production process, resulting in groundwater pollution. The groundwater in the plant area is now being investigated, and injection repairs are decided based on the investigation results. Move the direct-push drilling rig to the point that needs to be investigated. First, take quick groundwater sampling. Use a small connector to connect the drill pipe to the casing. Inside the casing is the injection head, and the bottom of the injection head is connected to the drill bit. The direct push drilling rig uses its own gravity and the impact force of the hydraulic impact hammer to penetrate the drill bit device into the groundwater pollution. During the penetration process, the casing covers the injection head and protects the injection hole to prevent soil and impurities from clogging during the drilling process. Injection hole and injection cavity. When the groundwater sampling position is reach...

Embodiment 2

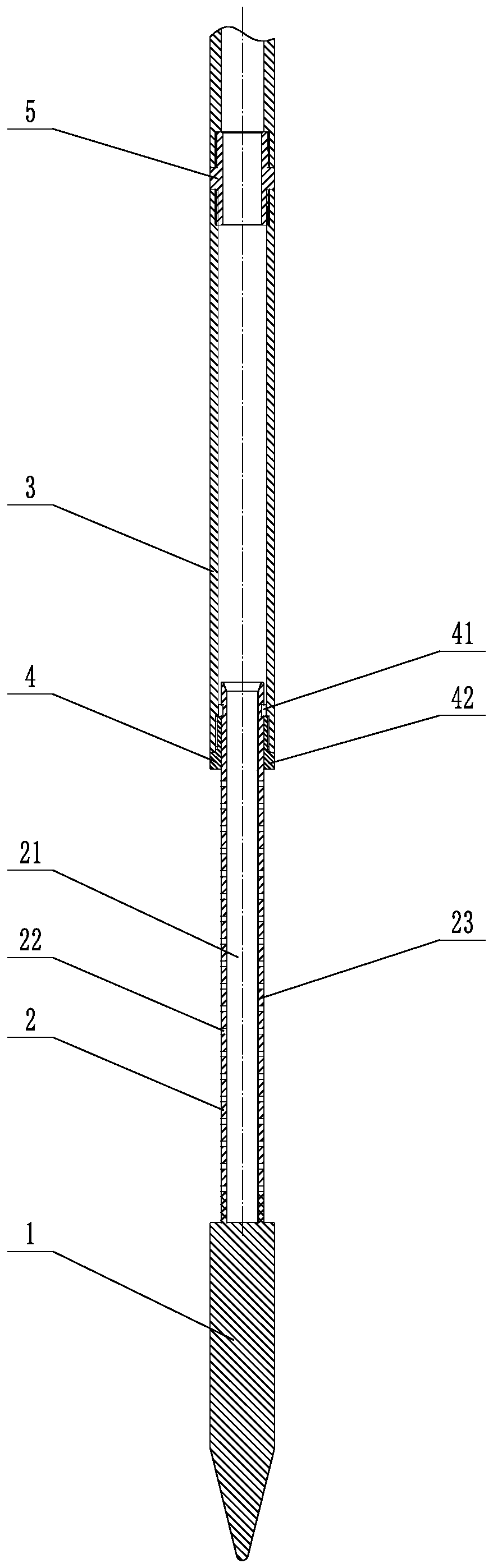

[0032] When it is necessary to carry out injection repair on contaminated groundwater, pull out the entire drill bit device from the surface, wash it with clean water, and use the large connector and the small connector to connect the drill pipe, the injection module and the casing. At this time, you can Choose to remove the stainless steel filter in the injection chamber. The direct-push drilling rig penetrates the drill bit device into the groundwater and soil pollution that needs to be repaired. During the penetration process, the spring is in a compressed state, resisting the upper injection valve to block the injection channel of the large connector, and the sleeve covers the injection cavity and injection hole. , to prevent soil and impurities from blocking the injection hole during drilling. When the repair depth is reached, the drill pipe is slightly pulled upwards, and the casing slides up to expose the injection channel. The injection agent enters the hollow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com