System and method capable of carrying out flue gas denitration and efficiency increasing through ozone

An ozone and flue gas technology, applied in the field of industrial waste gas purification, environmental protection and energy, can solve the problems of high site requirements, complex fuel, large ammonia escape, etc., and achieve the effects of saving space, ensuring normal use, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

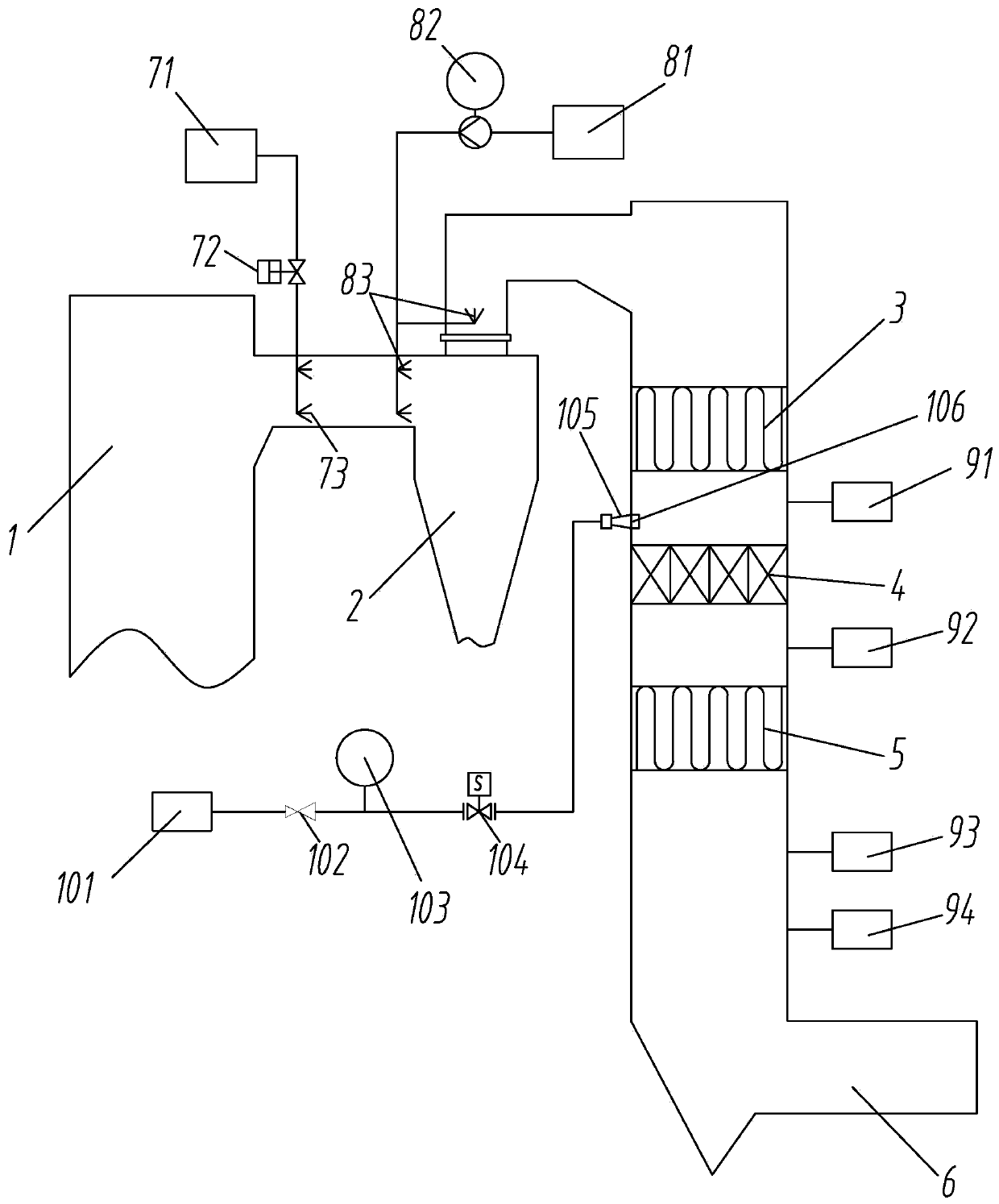

[0025] Such as figure 1 As shown, a system for flue gas denitrification and efficiency enhancement using ozone includes a circulating fluidized bed boiler 1 and an online monitoring system. The outlet pipe of the circulating fluidized bed boiler 1 is connected to a cyclone separator 2, and the main The function is to remove the solid particle impurities carried in the flue gas as much as possible. The outlet pipe of the cyclone separator 2 is connected with a flue 6, and the flue 6 is sequentially equipped with a high-temperature economizer 3, a denitrification catalyst 4, and a medium / low temperature coal-saving device 5, the outlet pipe of circulating fluidized bed boiler 1 is connected with an ozone generating system, the ozone generating system can generate ozone and transport ozone to the outlet pipe of circulating fluidized bed boiler 1, the inlet pipe of cyclone separator 2 and The outlet pipes are connected with an ammonia water supply system, which can generate ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com