A Harmonic Driven Crank Rocker Rotary Steering Gear

A harmonic drive, rotary technology, applied in the direction of transmission, mechanical equipment, aircraft parts, etc., can solve the problems of increasing system error, increasing the mass of the steering gear, and large installation space, and increasing the ratio of the steering gear and reducer. , Realize the effect of precision transmission and high precision transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

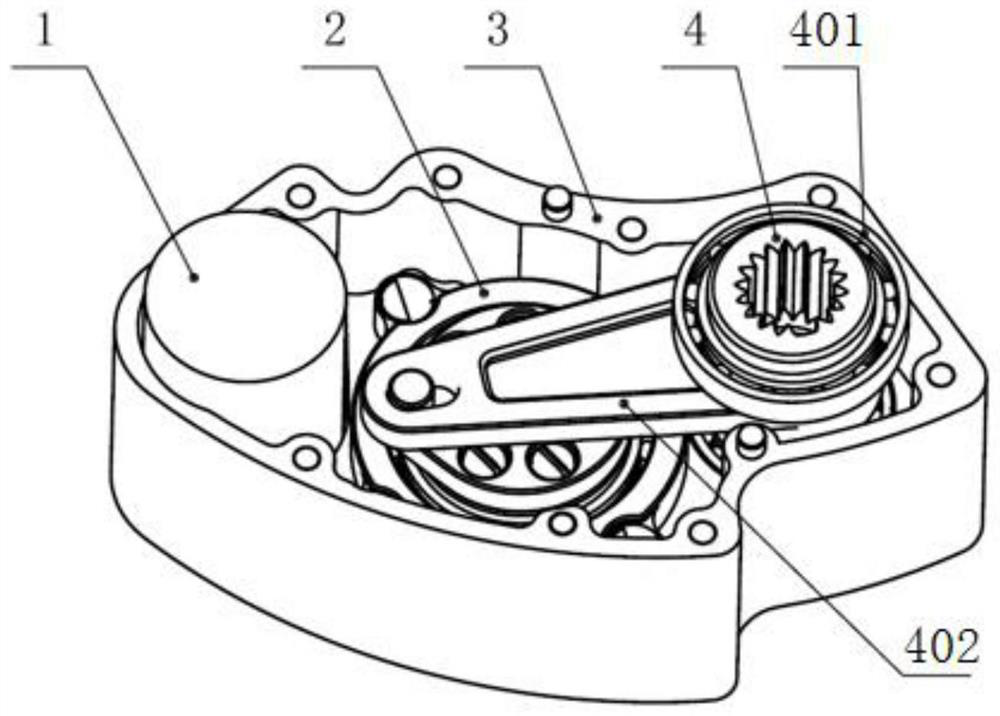

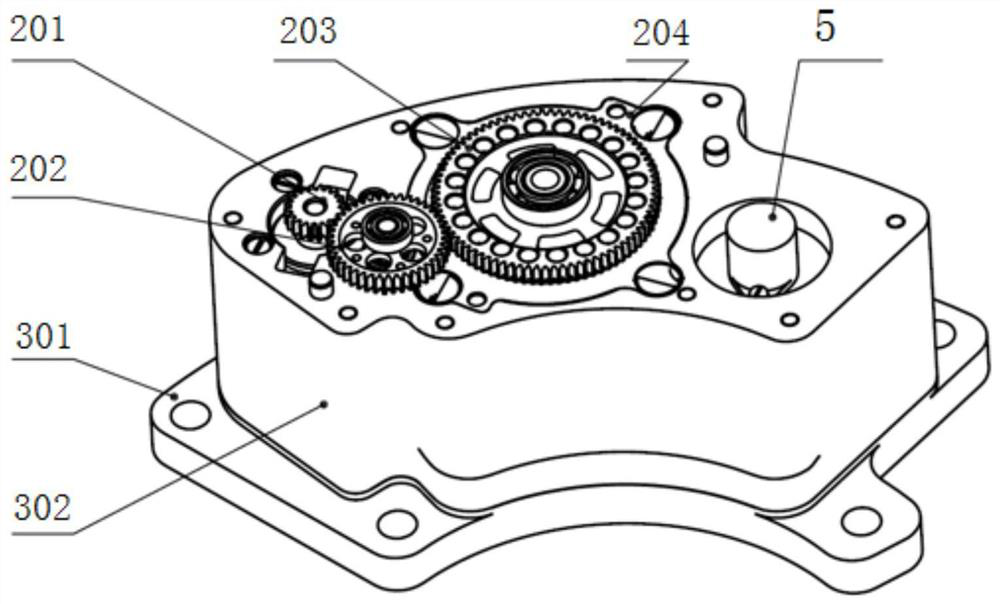

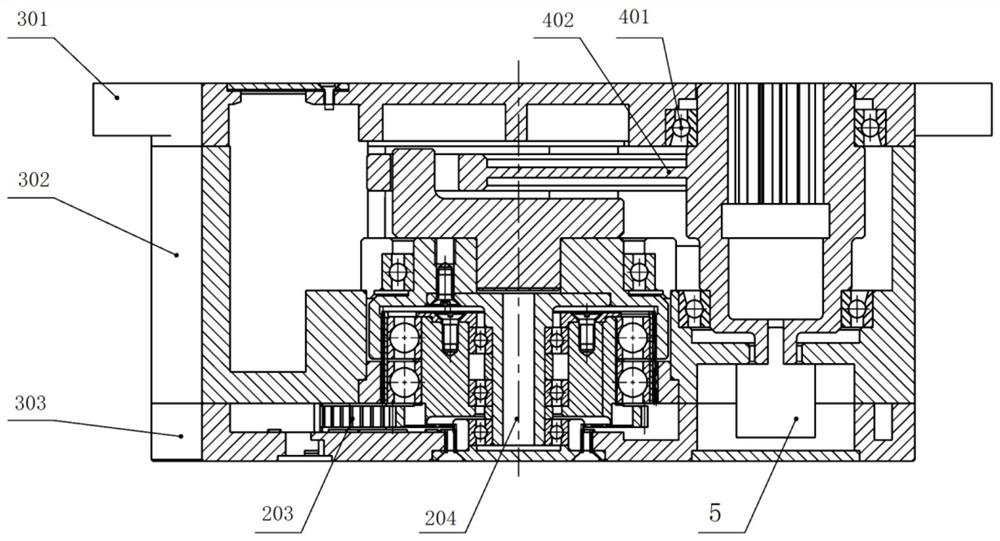

[0025] figure 1 It is a schematic structural diagram of the harmonic drive crank-rocker arm rotary steering gear in the embodiment of the present invention after the base is removed. figure 2 It is a schematic structural diagram of the harmonic drive crank-rocker arm rotary steering gear in the embodiment of the present invention after removing the upper end cover. like figure 1 and figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com