Temporary plugging ball impact and polishing testing device and method for shale gas horizontal well fracturing

A technology of testing device and temporary plugging ball, applied in the field of oil and gas field exploration and development, can solve the problems of strict blasthole gradation, small size of temporary plugging ball, and no test manifold for impacting and grinding effect of temporary plugging ball, so as to achieve impact and grinding. Accurate statistics of times, simple structure, and high data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

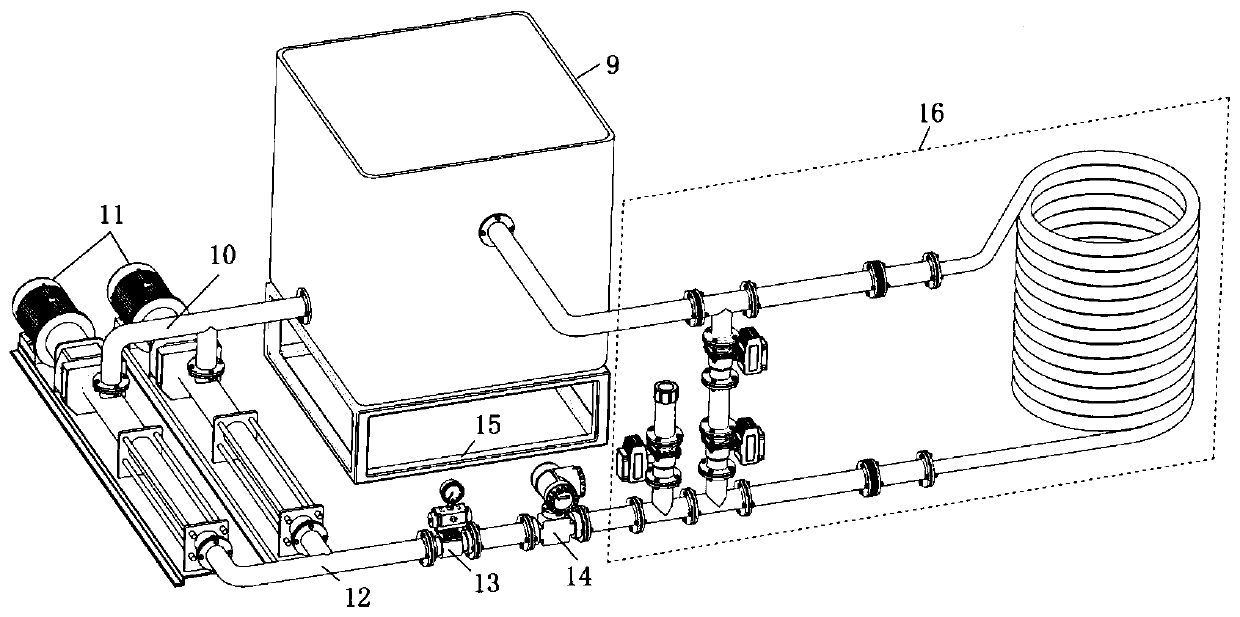

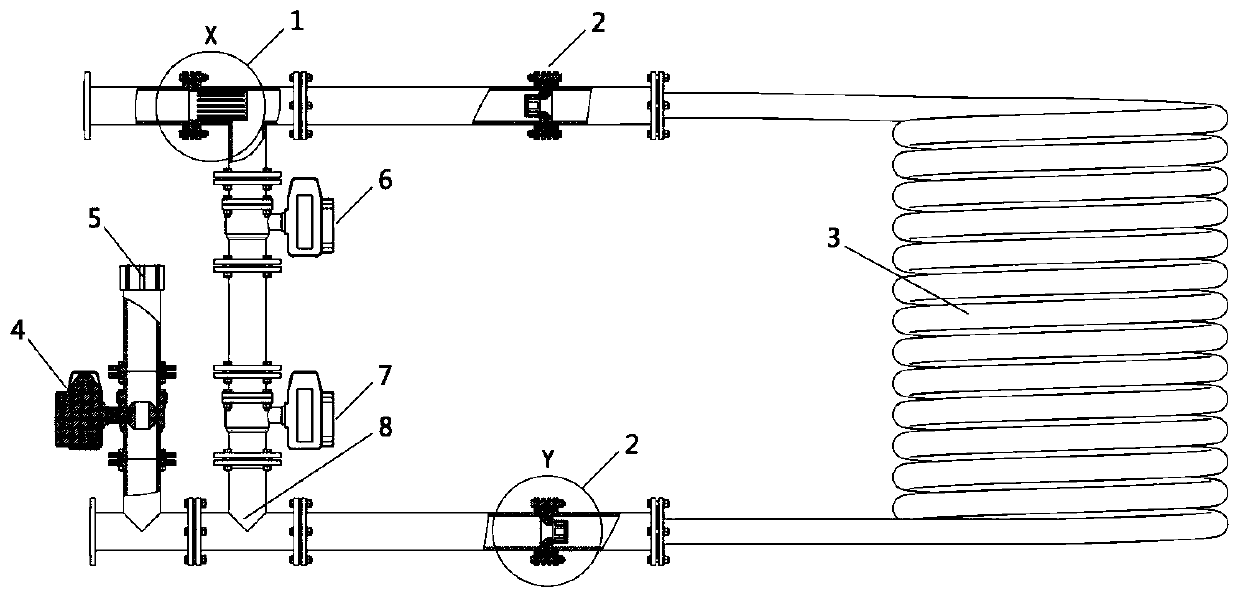

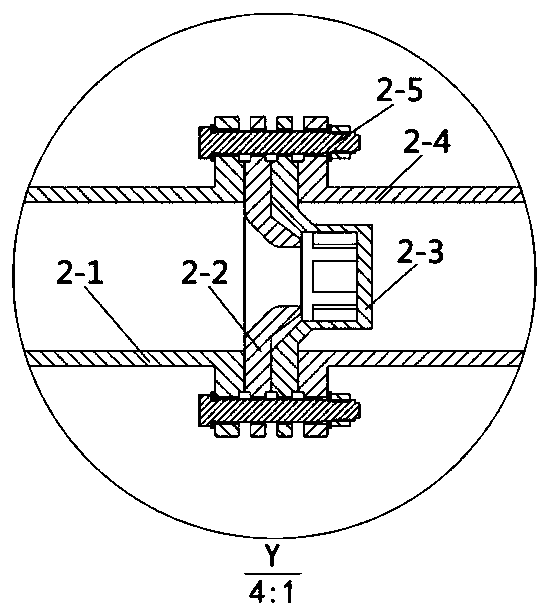

[0032] Such as figure 1 , 2 As shown, this embodiment provides a temporary plugging ball impact grinding test device for shale gas horizontal well fracturing, including a circulation pump 11, a liquid tank 9, a sensor, and an impact grinding test part. The pipeline 10 is connected to the liquid tank 9, and is connected to the impact grinding test part through the liquid discharge pipeline 12. The sensor is arranged on the liquid discharge pipeline 12. Pipe, accelerated collision sub-joint 2, spiral grinding oil pipe 3, solid capture and arresting short-circuit 1, the liquid discharge pipeline 12, accelerated-collision sub-joint 2, spiral grinding oil pipe 3, and solid-capturing and preventing short-connection 1 are connected through pipelines in sequence, The pitching standpipe is set up vertically, and the liquid discharge pipeline (main manifold) is connected. The ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com