Green and environment-friendly technique for melting and removing fracture flaws of tire and enhancing safety of tire

A green and environmentally friendly tire technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of font repair, pattern scar defects, aging cracks, premature loosening, etc., to save penetrating damage and service life Continuing and enhancing the effect of quality and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

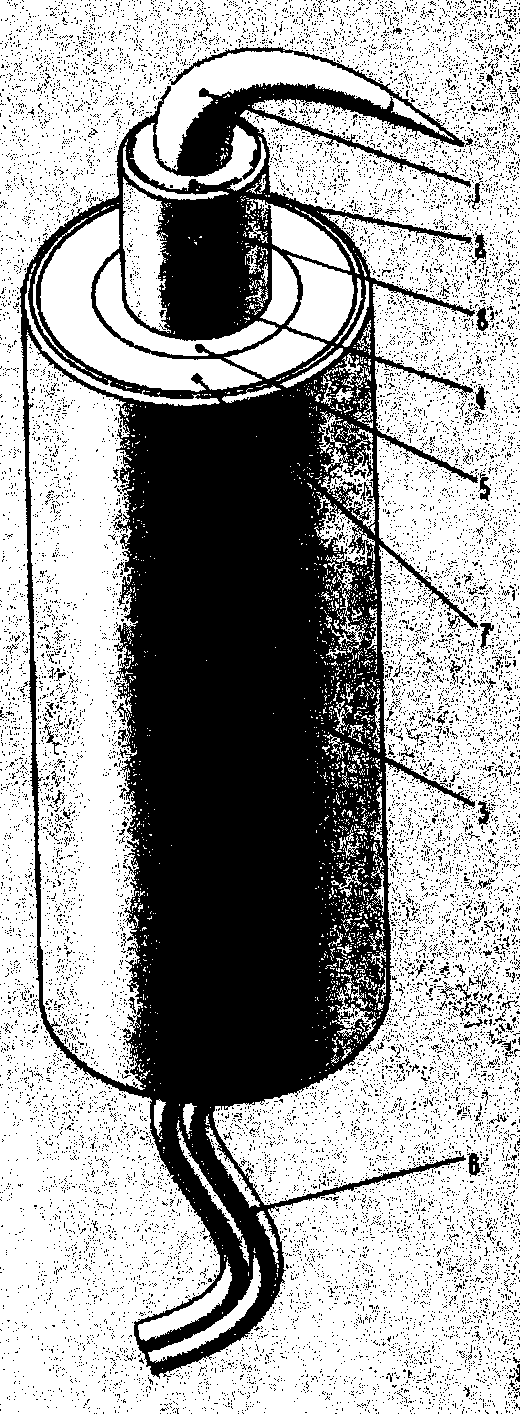

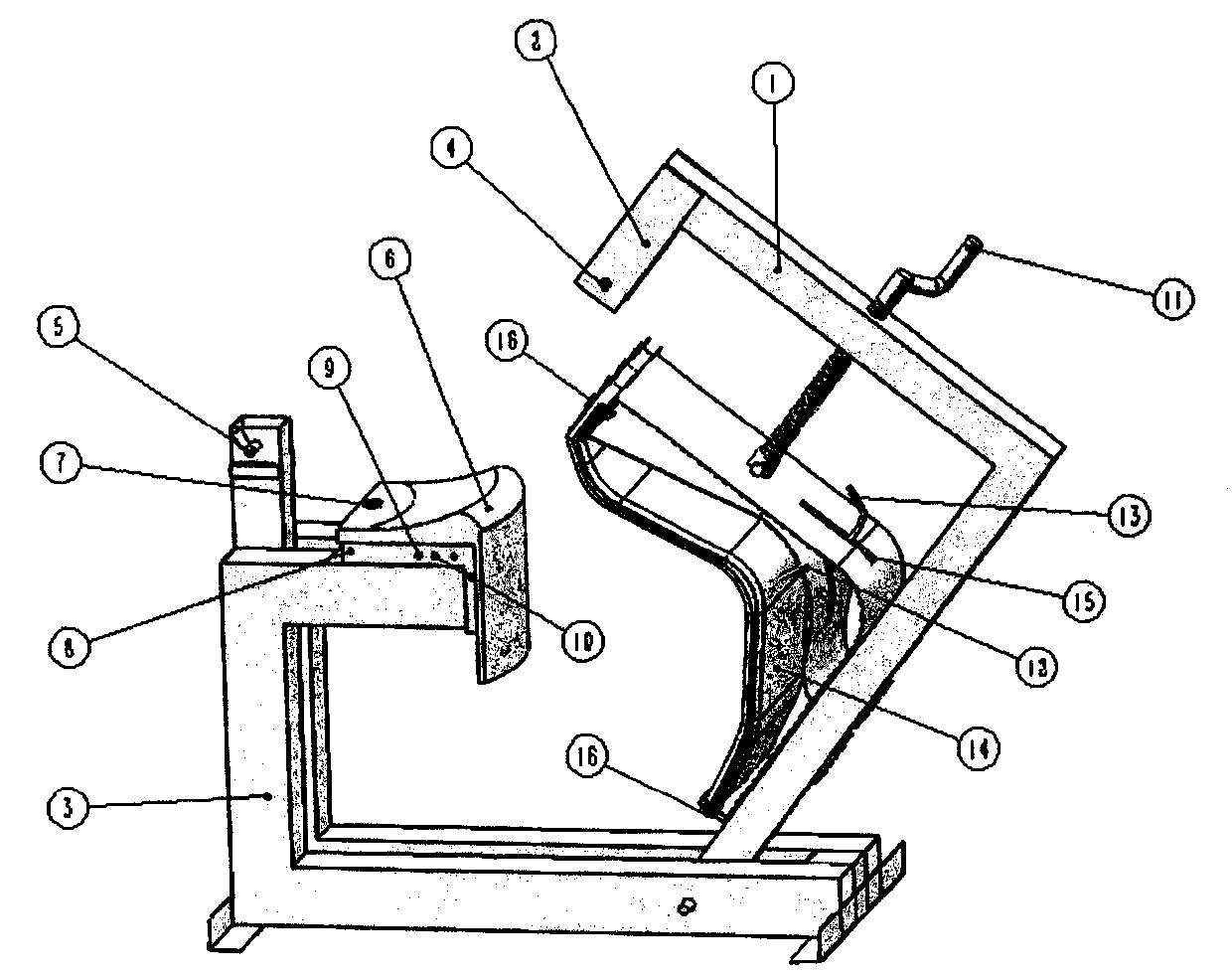

[0022] The subdivided procedures of the specific implementation steps are as follows: grinding, cleaning, sewing, applying vulcanizing agent, patching the cord fabric pieces, adding seams, adding vulcanizing agent, filling raw rubber, baking rubber mold blocks, applying release agent, pasting Apply mold blocks, repair and ablate.

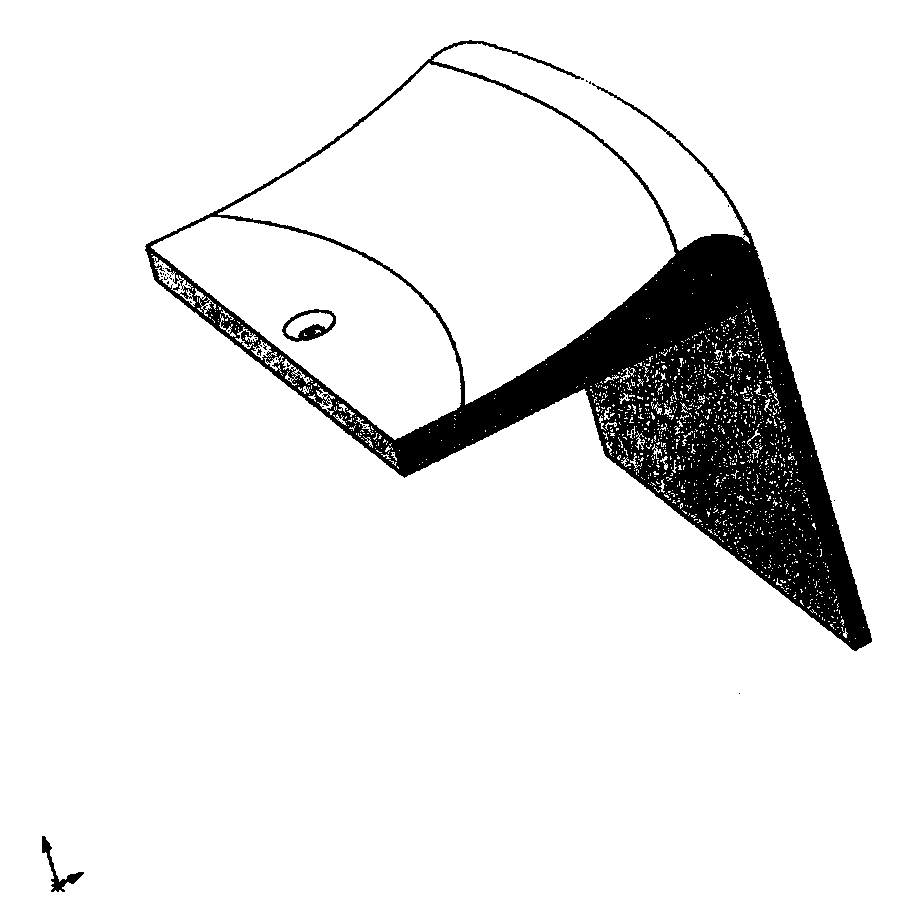

[0023] Step 1. Grinding: The grinding tool is an electric grinder. According to the specific injury of the damaged part of the rubber tire, the size and depth of the part, select the appropriate size of the grinding head. Ordinary tires use spherical grinding heads, and explosion-proof tires use mushroom-shaped grinding heads. The head is better, and the sanding goes as far as possible along the structure of the tire to prevent abrasion of the tire belt meridian.

[0024]Step 2. Cleaning: After grinding, lightly polish with a scouring pad to remove rubber burrs and residual rubber powder around the grinding wound.

[0025] Step 3. Suture: crochet a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com