Household water purification equipment based on deep purification

A kind of water purification equipment, deep technology, applied in water/sewage treatment equipment, water/sewage treatment, chemical instruments and methods, etc., can solve water pollution, affect the effective use of water, human health and environmental adverse effects, etc., to achieve The effect of improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

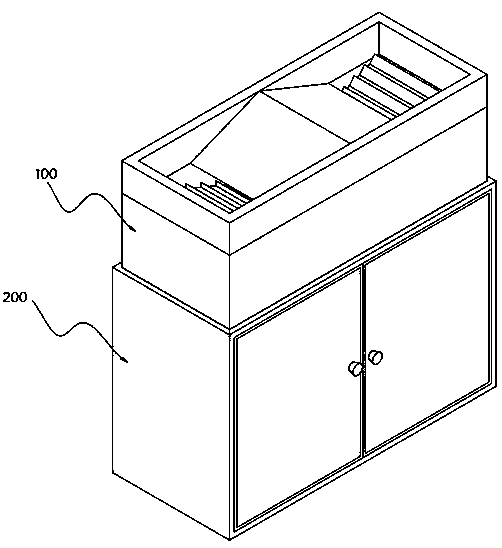

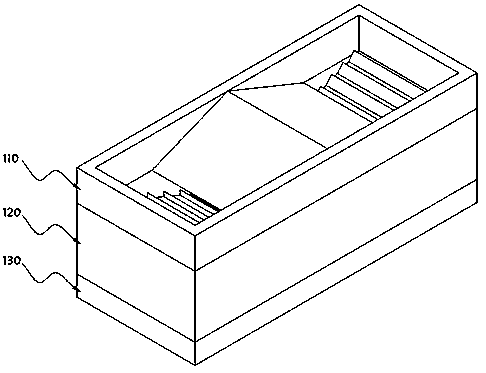

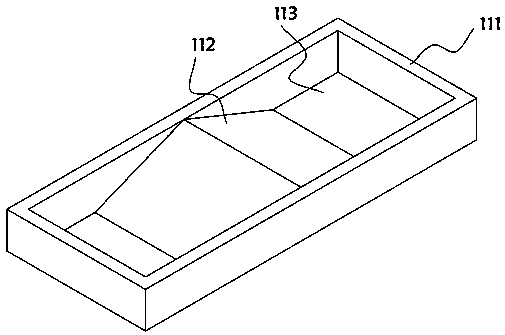

[0073] see Figure 1-Figure 17 As shown, the present invention provides household water purification equipment based on deep purification, including an initial filter chamber 100 and a deep purification box 200 installed at the bottom of the initial filtration warehouse 100, and the interior of the deep purification box 200 includes at least:

[0074] Filler purification device 210, the filler purification device 210 comprises a filler purification box 211, the filler purification box 211 is a cylindrical structure with an opening on the top, the inside of the filler purification box 211 is provided with a filler purification cylinder 212, and the interior of the filler purification cylinder 212 is provided with There is a filter cylinder 2125 for placing water purification fillers. The water purification fillers are preferably alum. After alum dissolves in water, it is ionized to produce Al3+, which combines with OHˉ produced by water ionization to form aluminum hydroxide, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com