Source bottle and semiconductor equipment

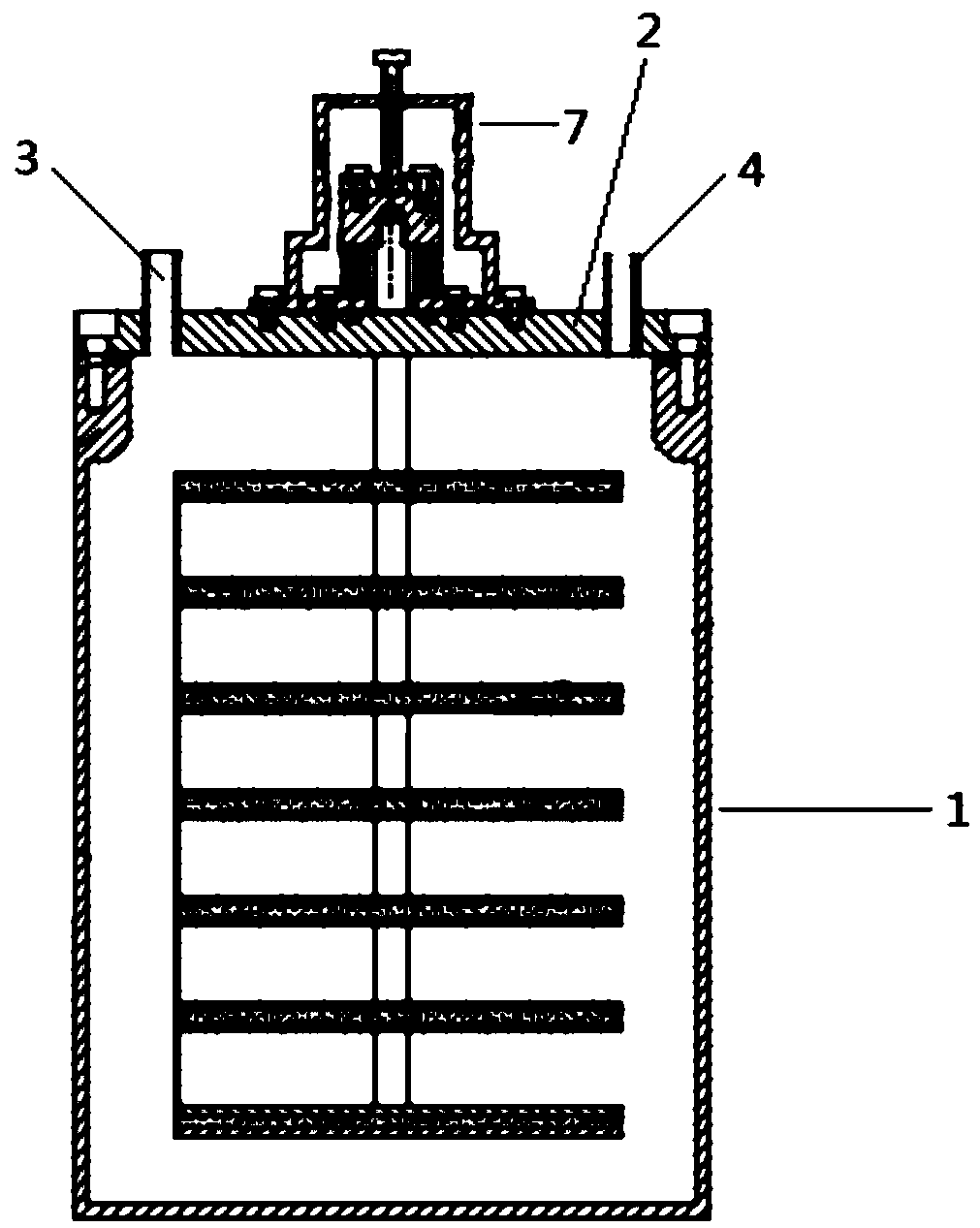

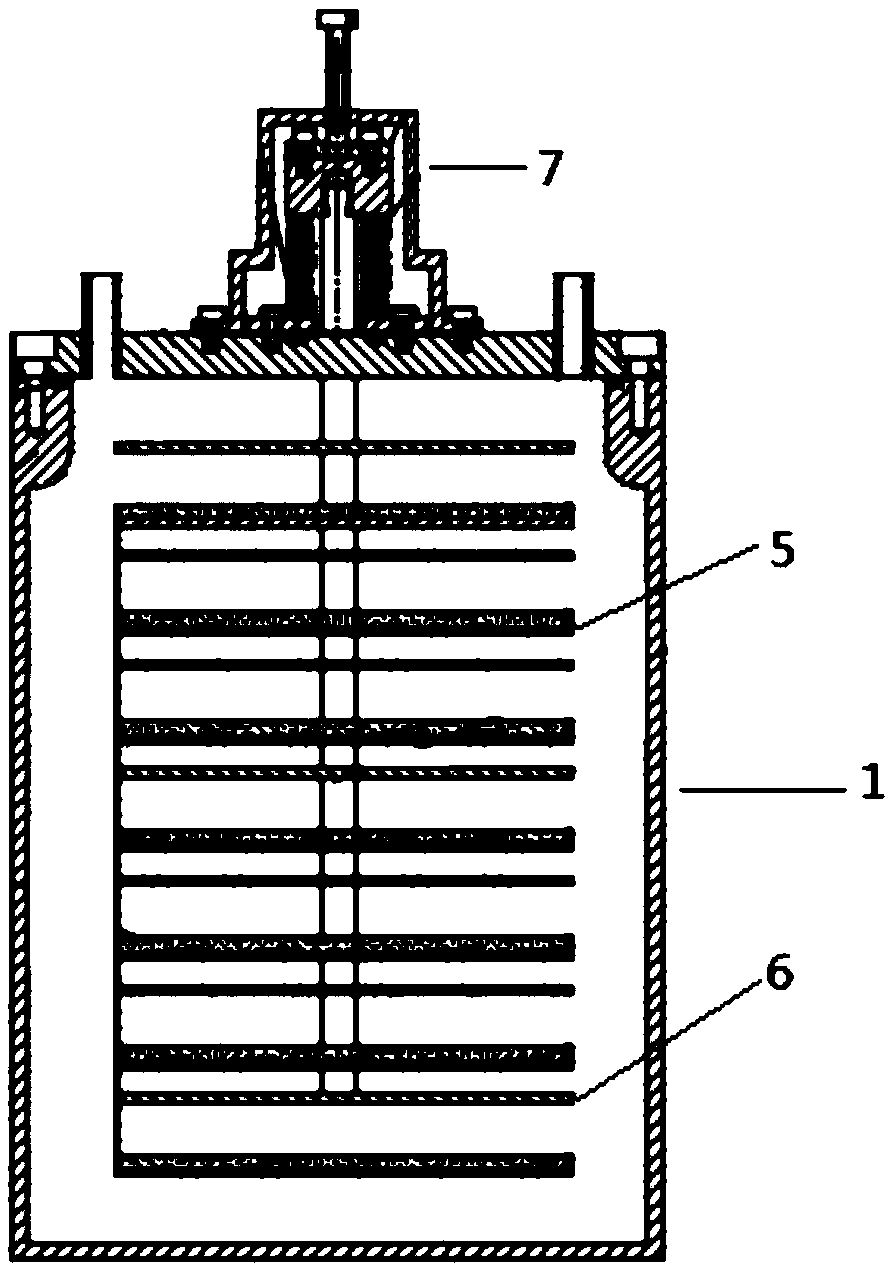

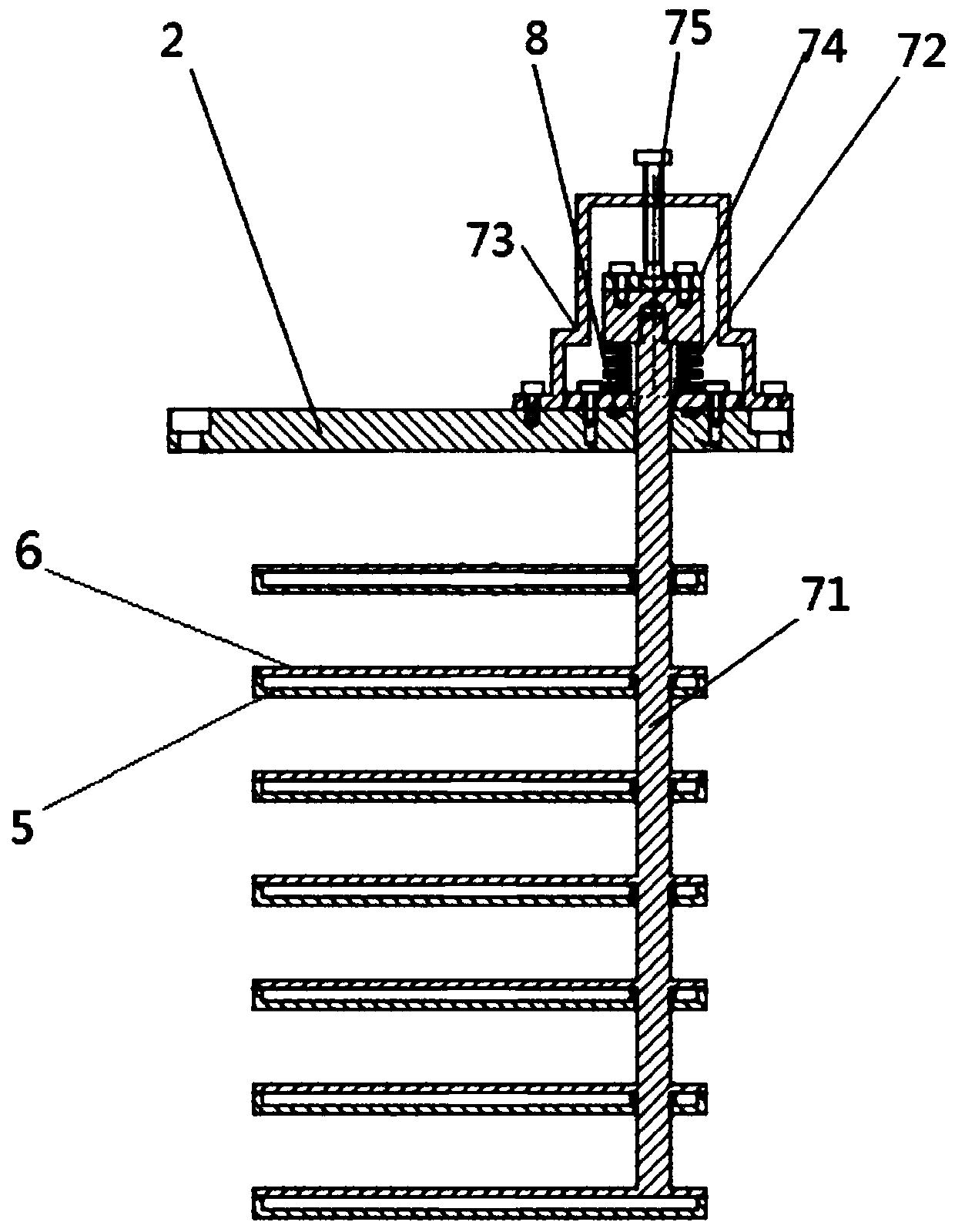

A source bottle and bottle cap technology is applied in the field of source bottles and semiconductor equipment, which can solve the problems that the solid powder source cannot be flattened, waste time, and the shape of the solid powder source surface cannot be determined and guaranteed, so as to solve the problem of insufficient solid source vapor concentration, The effect of increasing the steam concentration and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0060] In another embodiment of the present invention, a guide hole is vertically provided in the bottle cap 2, and the air intake pipe 3 extends to the outside of the confined space through the guide hole; and the guide hole can limit the rotational freedom of the air intake pipe 3.

[0061] In the embodiment of the present invention, the degree of freedom of the intake pipe is limited by the guide hole to ensure the multi-directional rotation of the intake pipe in the confined space. Further, the tray fixed with the intake pipe can be rotated in multiple directions in the confined space, thereby facilitating Loading of solid state sources.

Embodiment 4

[0063] For the above-mentioned source bottle, the embodiment of the present invention also provides a semiconductor device, including a reaction chamber, a carrier gas pipeline, a source bottle and an air inlet pipeline, wherein the carrier gas pipeline is used to transport the carrier gas to the source bottle; For containing the solid-state source, the source bottle is the source bottle in the above embodiment; the gas inlet line is used to deliver the carrier gas and reaction gas in the source bottle to the reaction chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com