Method for comprehensively recycling pulping waste liquid

A pulping waste liquor and black liquor technology, which is applied in the fields of pulping waste liquor combustion, pulping liquid regeneration, green liquor and white liquor treatment, etc., can solve the problems of pulping and papermaking wastewater pollution and difficult treatment, etc. Achieve the effect of fine process, reduce production cost, and recycle chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

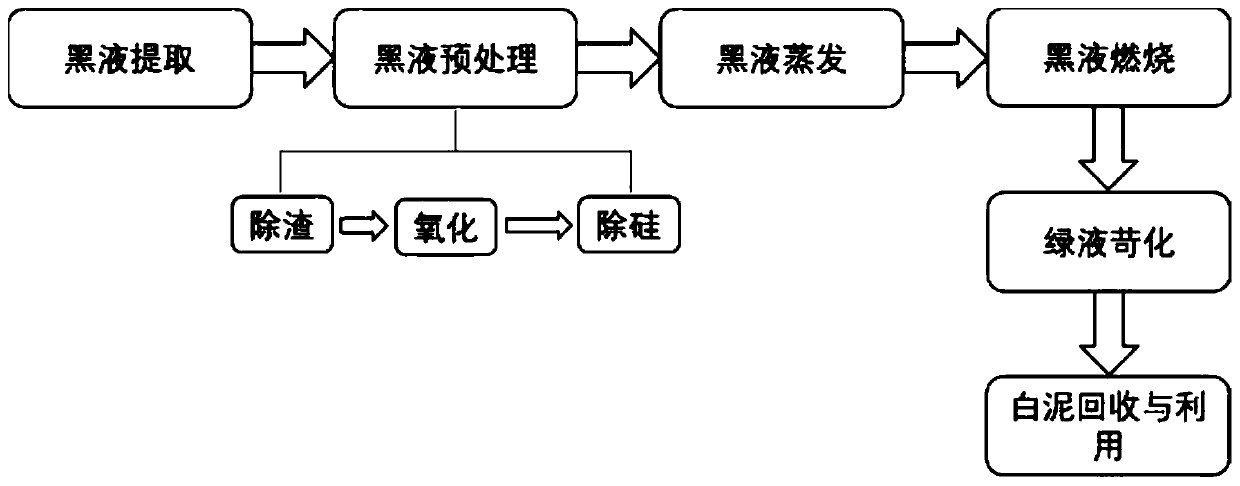

[0056] A method for comprehensive recycling of pulping waste liquid in the present invention, the flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0057] Step 1, extracting the dilute black liquor from the pulping cooking liquor, then pretreating the dilute black liquor, and finally evaporating and concentrating the pretreated dilute black liquor by using a mixed-flow indirect evaporation method;

[0058] The components of the dilute black liquor extracted in step 1 are 70% combustible organic matter, 30% inorganic matter, and the inorganic matter includes residual chemicals in the cooking waste liquid, such as NaOH, NaOH 2 S, and the metal base combined with the organic matter in the pulping raw material, and the inorganic components brought by the pulping raw material itself.

[0059] In step 1, the pretreatment of dilute black liquor includes deslagging, oxidation, and silicon removal, and deslagging refers to the removal of fine fibers and ...

Embodiment 2

[0079] A method for comprehensive recycling of pulping waste liquid in the present invention, the flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0080] Step 1, extracting the dilute black liquor from the pulping cooking liquor, then pretreating the dilute black liquor, and finally evaporating and concentrating the pretreated dilute black liquor by using a mixed-flow indirect evaporation method;

[0081] The components of the dilute black liquor extracted in step 1 are 70% combustible organic matter, 30% inorganic matter, and the inorganic matter includes residual chemicals in the cooking waste liquid, such as NaOH, NaOH 2 S, and the metal base combined with the organic matter in the pulping raw material, and the inorganic components brought by the pulping raw material itself.

[0082] In step 1, the pretreatment of dilute black liquor includes deslagging, oxidation, and silicon removal, and deslagging refers to the removal of fine fibers and ...

Embodiment 3

[0102] A method for comprehensive recycling of pulping waste liquid in the present invention, the flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0103] Step 1, extracting the dilute black liquor from the pulping cooking liquor, then pretreating the dilute black liquor, and finally evaporating and concentrating the pretreated dilute black liquor by using a mixed-flow indirect evaporation method;

[0104] The components of the dilute black liquor extracted in step 1 are 70% combustible organic matter, 30% inorganic matter, and the inorganic matter includes residual chemicals in the cooking waste liquid, such as NaOH, NaOH 2S, and the metal base combined with the organic matter in the pulping raw material, and the inorganic components brought by the pulping raw material itself.

[0105] In step 1, the pretreatment of dilute black liquor includes deslagging, oxidation, and silicon removal, and deslagging refers to the removal of fine fibers and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com