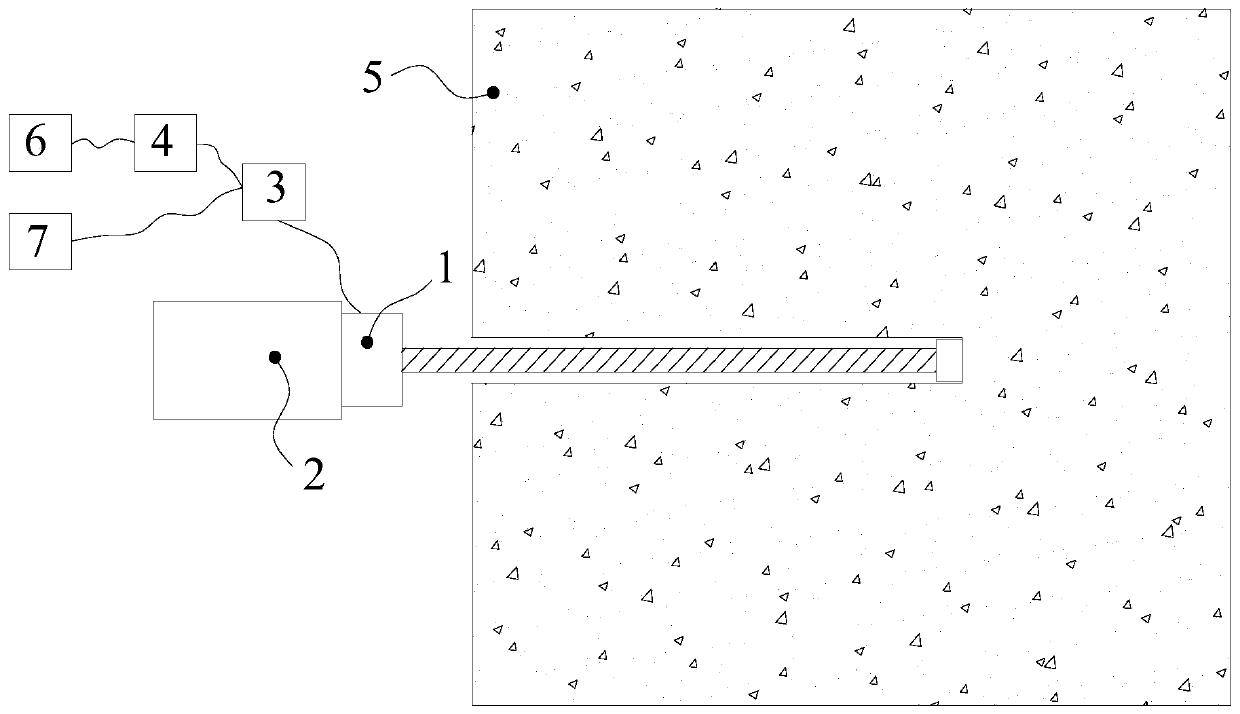

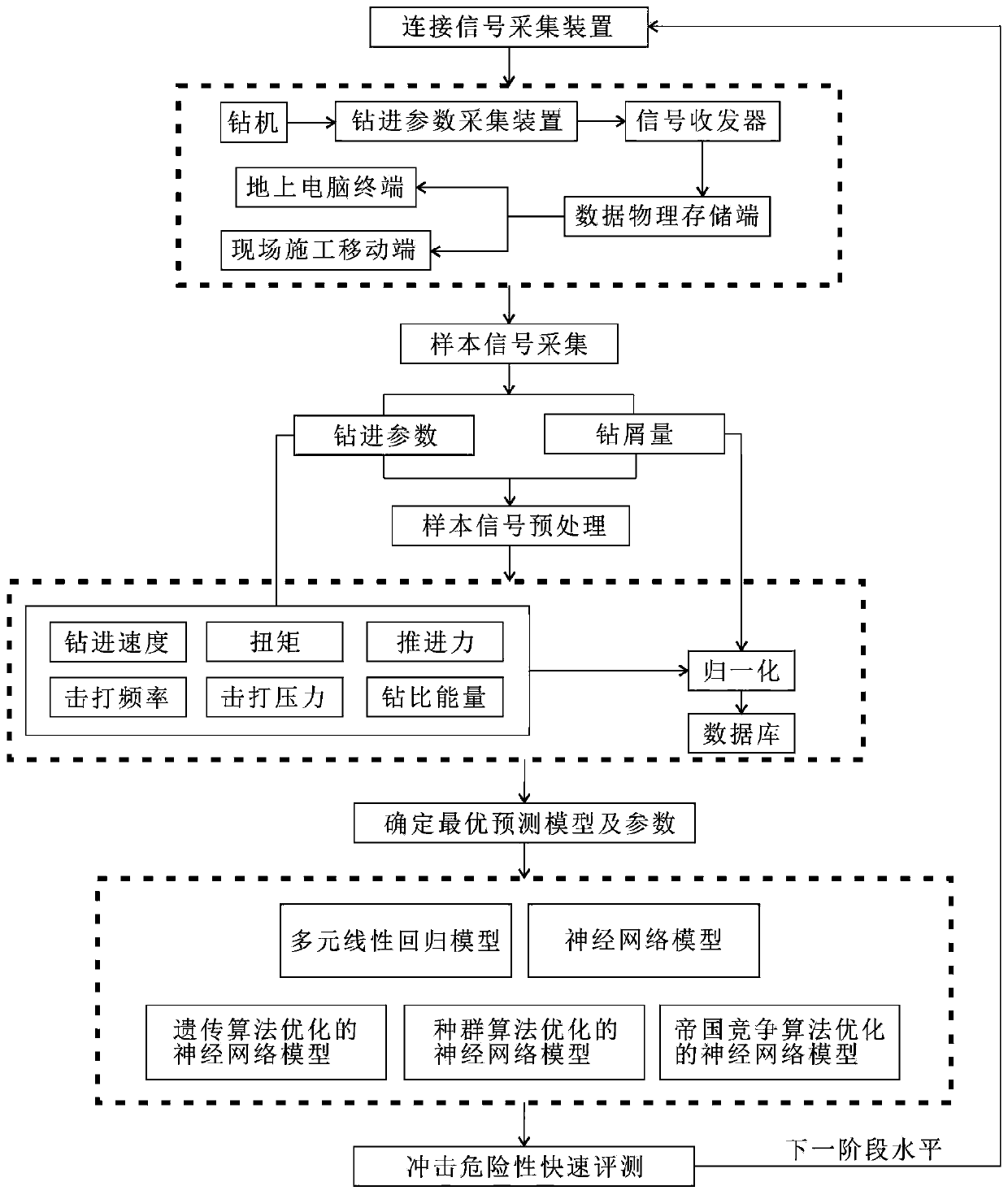

Coal seam impact risk real-time evaluation method based on measurement while drilling technology

A measurement-while-drilling, risky technology, applied in measurement, neural learning methods, earth-moving drilling, etc., can solve problems such as low efficiency, poor timeliness, and difficulty in acquiring sample data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to describe the overall operation process of the present invention more concisely, take the -300-meter horizontal mining stage of a mine as an example. A layer of coal (3# coal) is mined in this horizontal stage. The coal seam has been identified for its impact tendency. In order to have an impact tendency, the design and planning of this level of mining stage has a total of 10 mining working faces and 20 driving working faces. For all working faces, a comprehensive impact risk assessment must be carried out before mining and driving. The comprehensive assessment result is weak, The working face of medium and strong impact level needs to be monitored and evaluated during mining or tunneling. The method of the present invention is used to efficiently, quickly and accurately predict the risk of rock burst during mining or tunneling. For ease of description, each working face at this mining level is called the first working face, the second working face, the third w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com