Cheese powder, preparation method thereof and cheese-flavored food

A technology of cheese powder and cheese, which is applied in the food field, can solve the problems that the taste cannot meet the requirements of the market and the loss of flavor, and achieve the effect of pure and strong flavor, long aftertaste and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

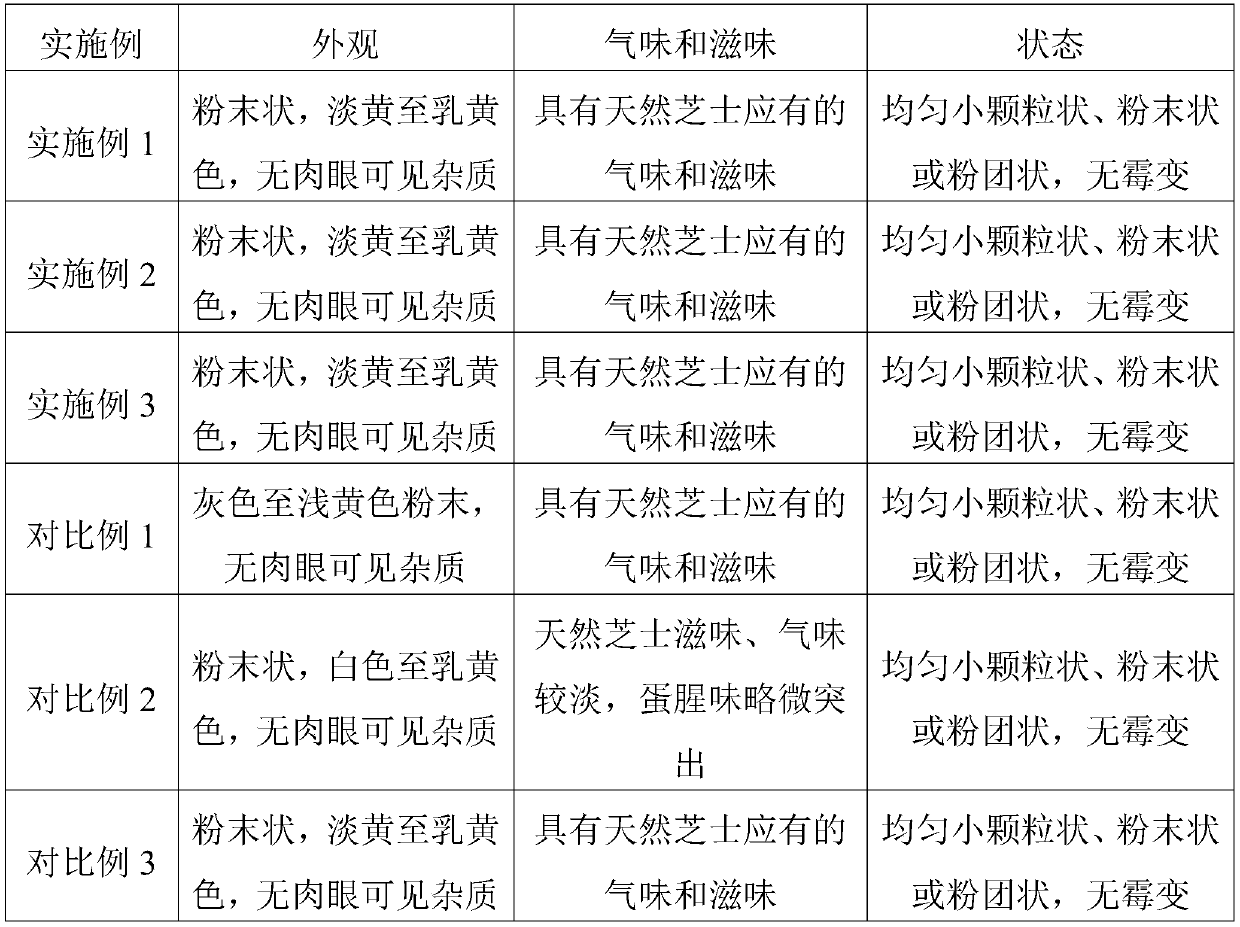

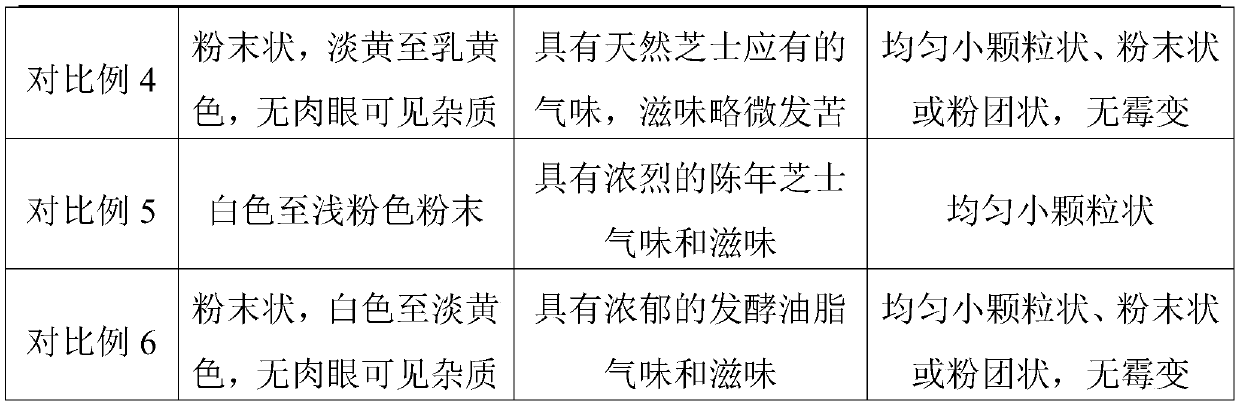

Examples

preparation example Construction

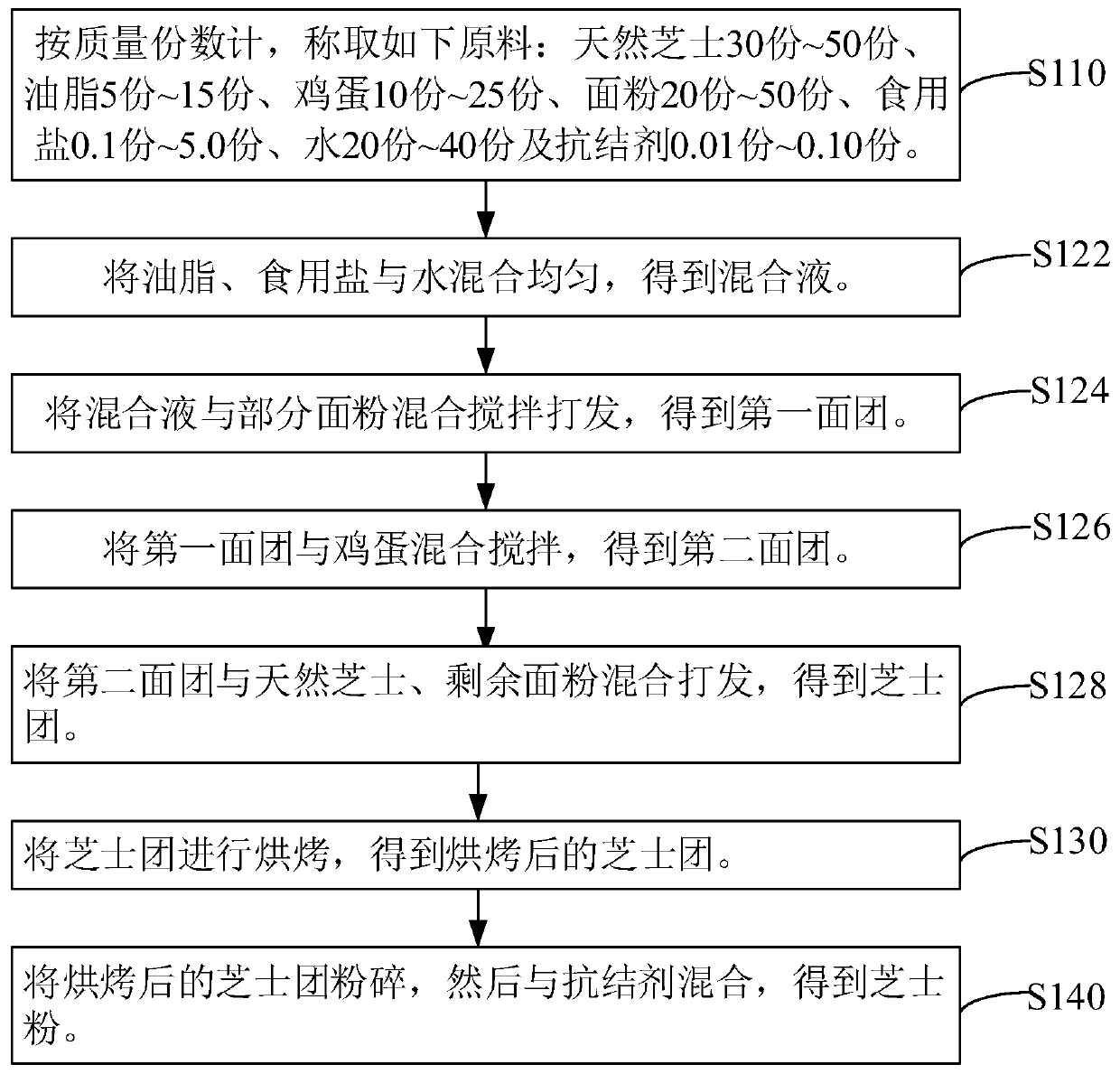

[0042] see figure 1 , the preparation method of the cheese powder of an embodiment, comprises the steps:

[0043] Step S110: Weigh the following raw materials in parts by mass: 30-50 parts of natural cheese, 5-15 parts of oil, 10-25 parts of eggs, 20-50 parts of flour, 0.1-5.0 parts of edible salt , 20 to 40 parts of water and 0.01 to 0.10 parts of anticaking agent.

[0044] The natural cheese in the cheese powder can provide the cheese powder with pure cheese flavor and nutrition required in the cheese powder. Specifically, the mass parts of natural cheese is 30, 35, 40, 45 or 50 parts. In one embodiment, the natural cheese is cheddar cheese.

[0045]The fat is selected from at least one of anhydrous cream, natural butter and margarine. Further, the oil is natural butter or margarine. Specifically, the mass parts of oil are 5 parts, 7 parts, 10 parts, 12 parts

[0046] or 15 servings. In cheese powder, the function of fat is to enhance the taste of cheese powder and en...

Embodiment 1

[0079] The preparation process of the cheese powder of the present embodiment is specifically as follows:

[0080] (1) Weigh each raw material according to the following parts by mass: 43 parts of natural cheese, 11 parts of oil, 15 parts of egg, 42 parts of flour, 2 parts of edible salt, 32 parts of water and 0.04 part of anticaking agent.

[0081] (2) Add 32 parts of water into the chopper, heat to 90°C, then add 11 parts of oil and 2 parts of edible salt, turn on the chopping paddle to dissolve and disperse the oil and salt evenly, and obtain a mixed solution.

[0082] (3) Transfer the mixture obtained in step (2) to a flour mixer, add 35 parts of flour, and then turn on the mixer for 8 minutes to beat it into the first dough, then turn off the mixer, and let stand to cool down.

[0083] (4) When the temperature of the first dough in step (3) is cooled to 40°C, add 15 parts of beaten whole eggs, and turn on the mixer again for 4 minutes to make the first dough absorb all th...

Embodiment 2

[0088] The preparation process of the cheese powder of the present embodiment is specifically as follows:

[0089] (1) Weigh each raw material according to the following parts by mass: 30 parts of natural cheese, 5 parts of oil, 10 parts of egg, 20 parts of flour, 0.1 part of edible salt, 20 parts of water and 0.01 part of anticaking agent.

[0090] (2) Add 20 parts of water into the chopping machine, heat to 80°C, then add 5 parts of oil and 0.1 part of edible salt, and turn on the chopping paddle to evenly dissolve and disperse the oil and edible salt.

[0091] (3) Transfer the product obtained in step (2) to a flour mixer, add 15 parts of flour, turn on the mixer and beat for 5 minutes, knead it into the first dough, turn off the mixer, and let stand to cool down.

[0092] (4) When the temperature of the first dough in step (3) is lowered to 40°C, add 10 parts of beaten whole eggs and turn on the mixer again for 3 minutes to make the first dough absorb all the egg liquid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com