Ship straight wing stabilization system

A straight-wing, ship technology, applied in the field of ship straight-wing anti-rolling system, can solve the problem of difficulty in large-scale gyro anti-rolling device, and achieve the effects of saving ship space, high propulsion efficiency, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

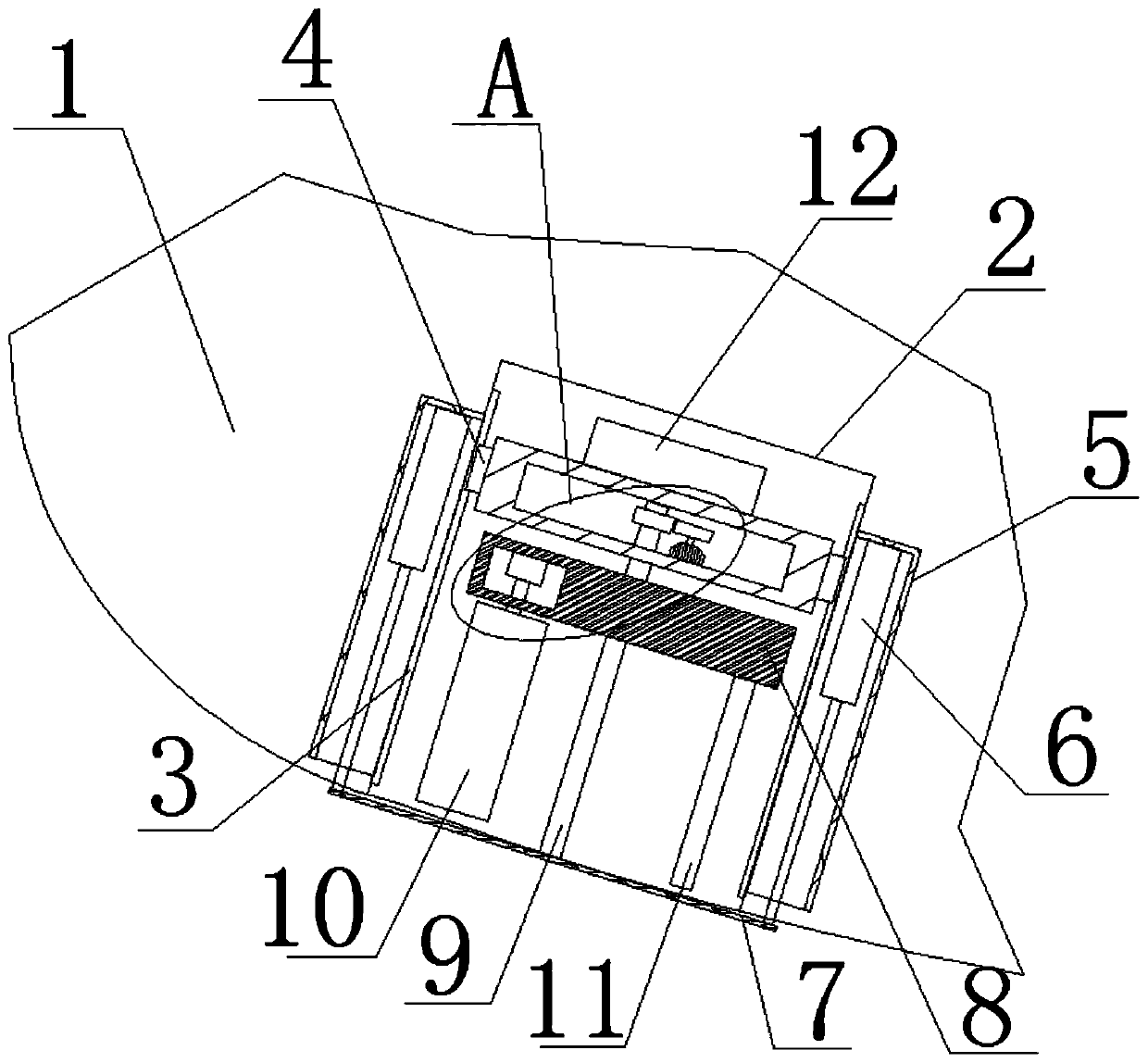

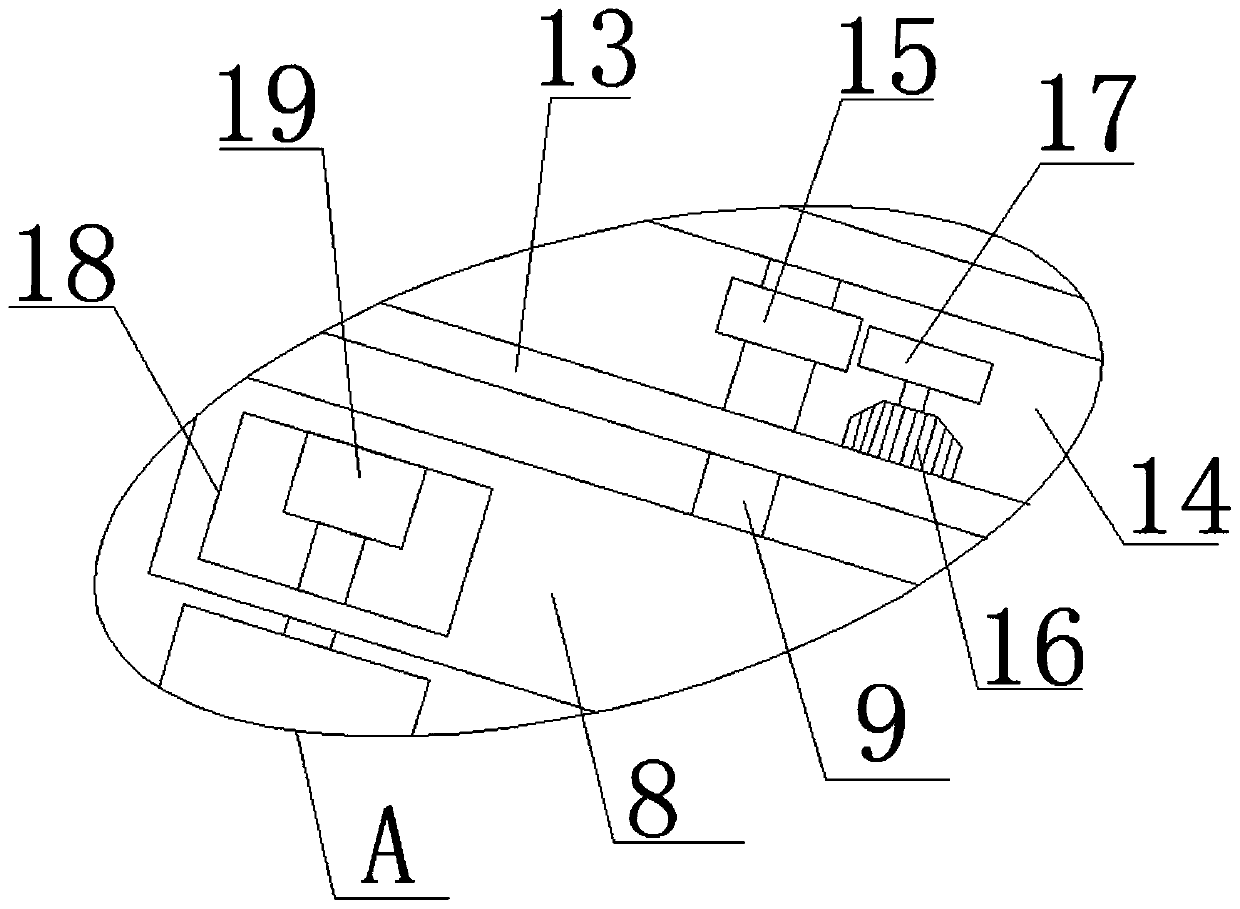

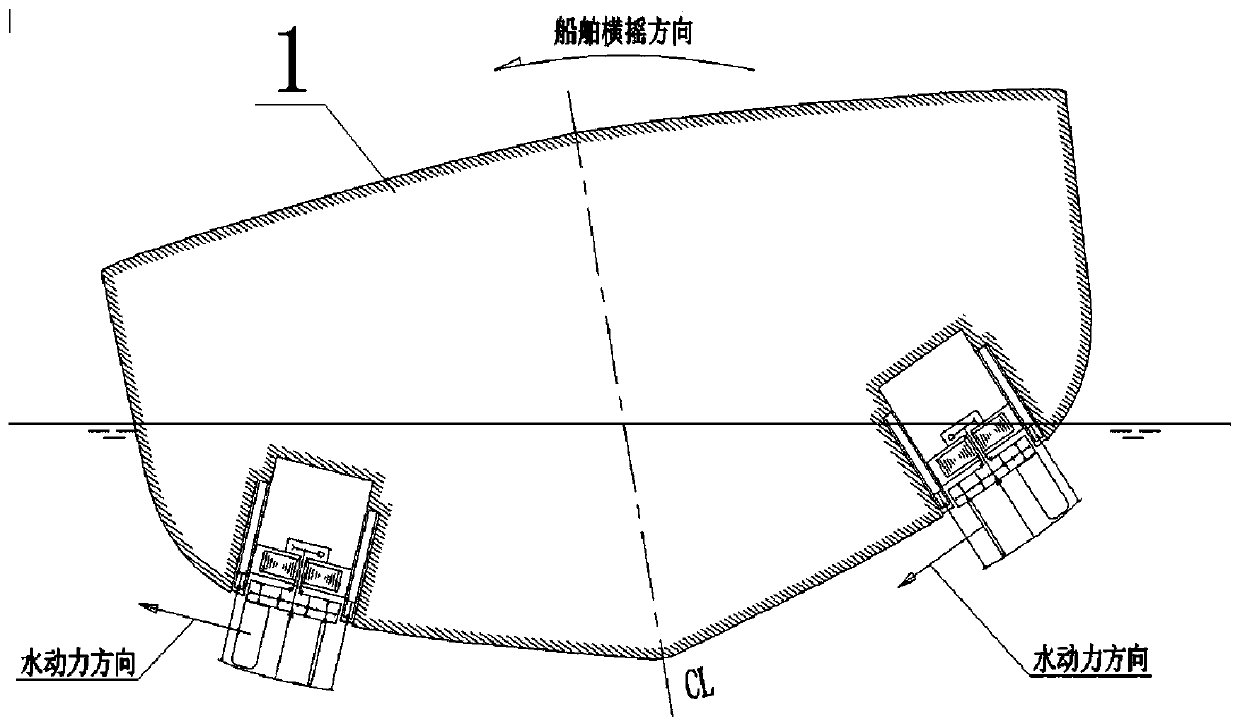

[0027] refer to Figure 1-4 , the straight-wing anti-rolling system of a ship includes a hull 1, and a placement groove 2 is provided on one side of the hull 1, and a straight-wing thruster is installed in the placement groove 2, and the straight-wing thruster includes a base 13, and the top of the base 13 is fixedly installed There is a rotor angle controller 12, a cavity 14 is provided on the base 13, a transmission shaft 9 is installed on the top inner wall of the cavity 14, and the bottom of the transmission shaft 9 extends to the outside of the base 13, and the top of the transmission shaft 9 is fixed. The first gear 15 is socketed, and one side of the first gear 15 is provided with a rotating motor 16 fixedly installed on the inner wall of the bottom of the cavity 14, and a second gear 17 is fixedly installed on the output shaft of the rotating motor 16, and the second gear 17 meshes with the first gear 15, the transmission shaft 9 is fixedly sleeved with the rotating di...

Embodiment 2

[0033] refer to Figure 1-4 , the straight-wing anti-rolling system of a ship includes a hull 1, and a placement groove 2 is provided on one side of the hull 1, and a straight-wing thruster is installed in the placement groove 2, and the straight-wing thruster includes a base 13, and the top of the base 13 is fixedly installed There is a rotor angle controller 12, which is used to control the angle of the rotor. A cavity 14 is provided on the base 13, and a transmission shaft 9 is installed on the top inner wall of the cavity 14, and the bottom of the transmission shaft 9 extends to the outside of the base 13. , the transmission shaft 9 is fixedly sleeved with a first gear 15, and one side of the first gear 15 is provided with a rotating motor 16 fixedly installed on the inner wall at the bottom of the cavity 14, and the rotating motor 16 can also be combined with a frequency converter and an asynchronous motor A second gear 17 is fixedly installed on the output shaft of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com