Laminated vacuum thermal insulation glass plate prepared from glass and stainless steel frame through metal brazing and isolation

A glass plate, stainless steel technology, applied in parallel glass structure, climate change adaptation, improvement of windows/doors, etc., can solve the problem of high yield, achieve the effect of high yield, good thermal insulation performance and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

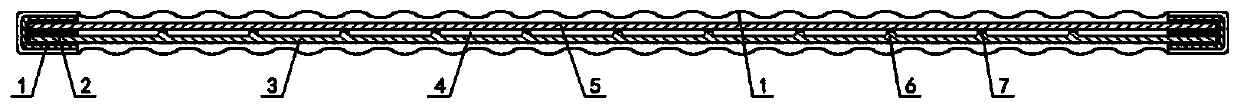

[0222] Such as figure 1 As shown: the upper tempered glass 5 passes through the "mountain"-shaped metal brazing layer 2, and the lower tempered glass 3 is distributed with dot matrix sintered support bumps 6, which correspond to each other in terms of contour shape and size, complementary buckle, and interval A vacuum interlayer 4 is formed. Through the closed-loop "U"-shaped stainless steel corrugated protective frame 1 and the brazing sealing of the "mountain"-shaped metal brazing layer 2, a glass plate frame is made to support a complementary buckle metal brazed stainless steel frame vacuum glass plate.

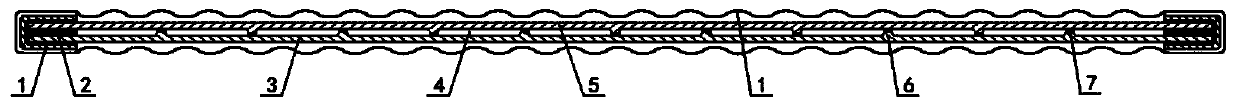

[0223] Such as figure 2 As shown: the upper tempered glass 5 and the lower tempered glass 3 are distributed with dot matrix sintering support bumps 6, and others are equivalent to figure 1 .

[0224] Such as image 3 Shown: the tempered glass 3 on the lower side is distributed with dot matrix tensile support bumps 8, and others are equivalent to figure 1 .

[0225] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com