Cast iron spheroidizing treatment system

A processing system and nodularizing bag technology, applied in the field of cast iron nodularizing treatment system, can solve the problems of poor coverage, nodularizing agent melting and floating, low absorption rate, etc., to reduce labor intensity, save production cost, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

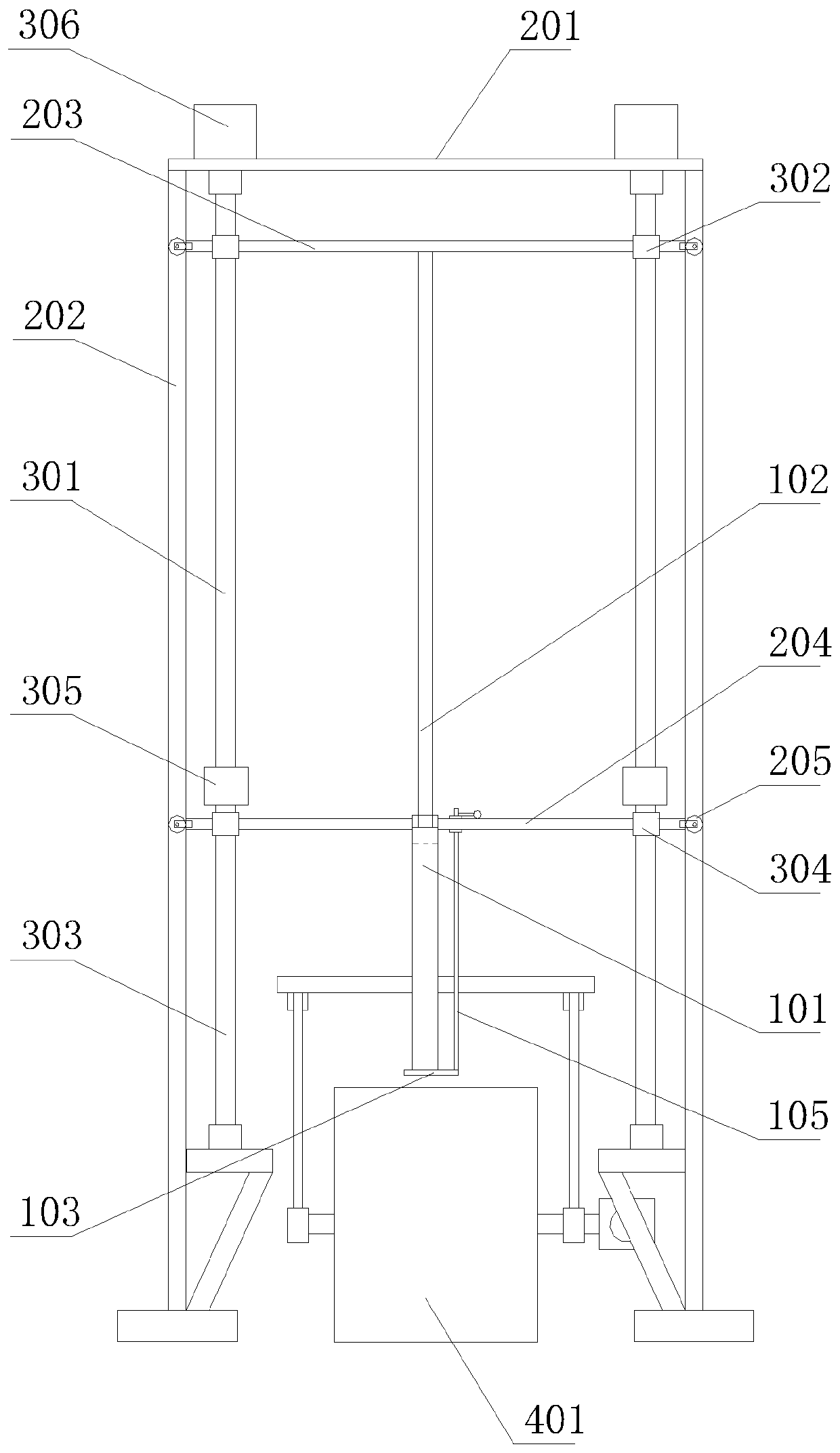

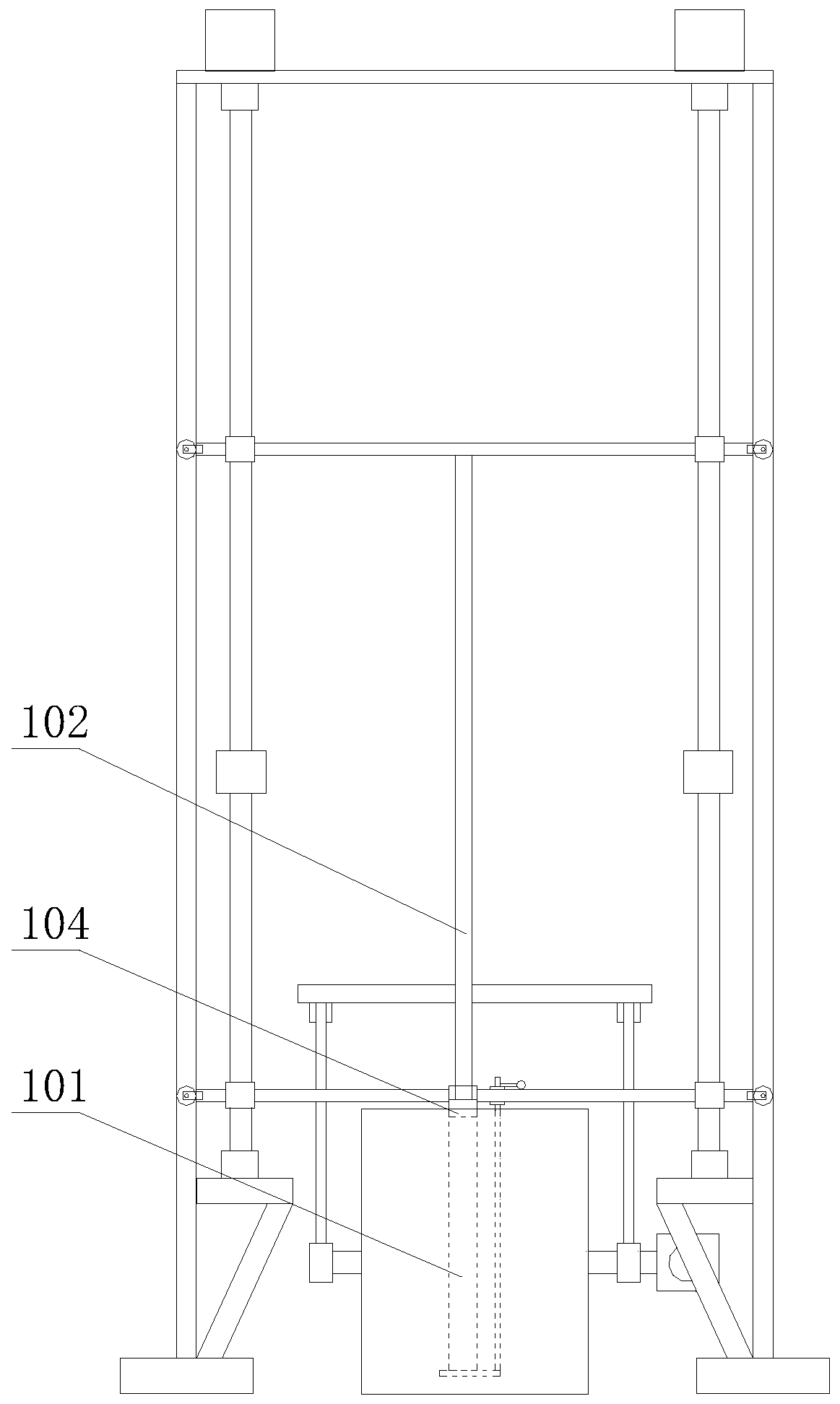

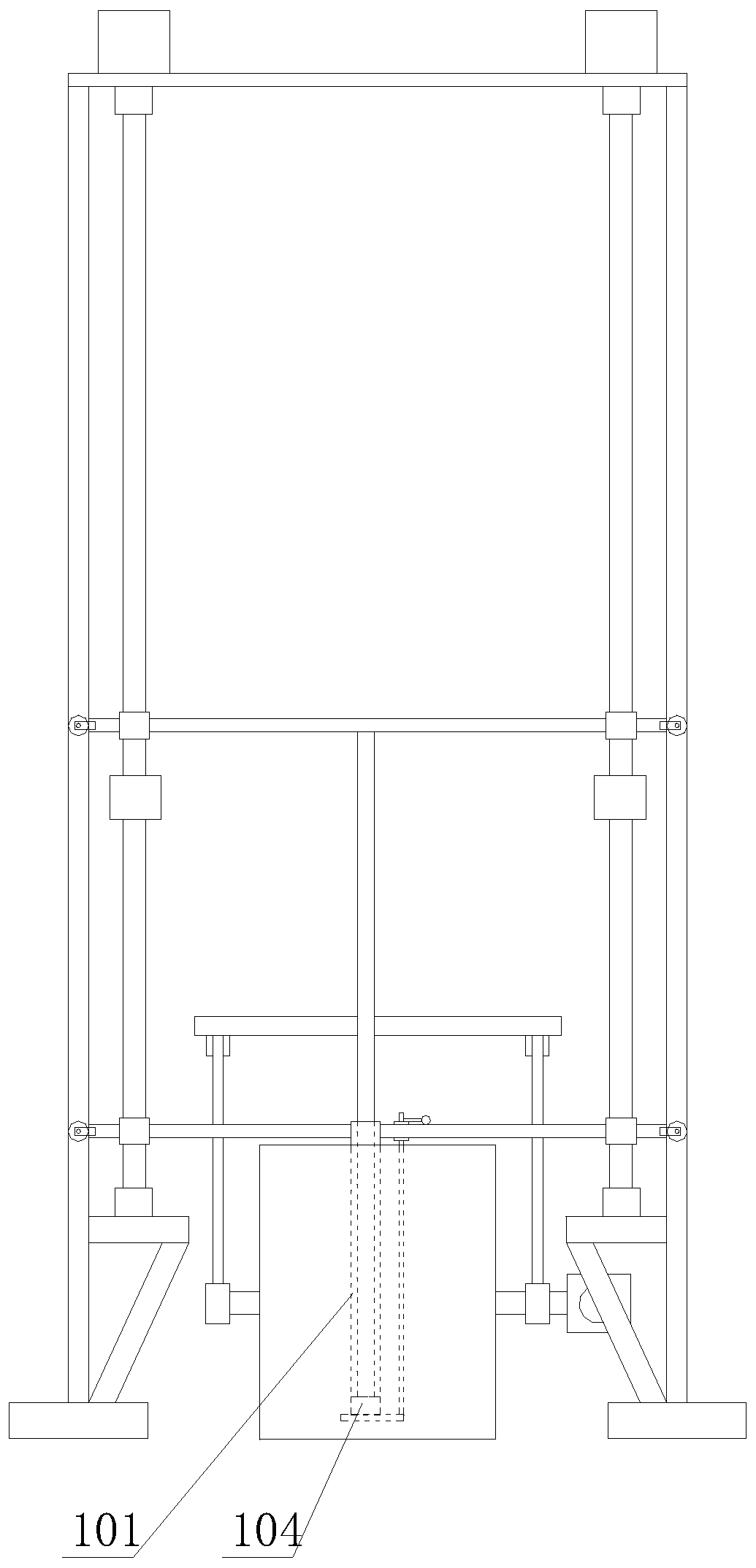

[0057] The accommodating part is a syringe made of refractory material. Since the syringe will enter the molten iron, the melting point of the syringe material is higher than the temperature of the molten iron. Graphite or refractory brick materials can be used. The ignition point of graphite under anaerobic conditions is at least Above 3000 degrees, when the temperature rises, graphite not only does not soften but strengthens. The syringe includes an injection barrel 101 for containing the nodulizing agent and a push rod 102 capable of moving up and down in the injection barrel 101; an injection hole is opened at the bottom of the injection barrel 101, and the release valve plate is arranged on the injection barrel 101. At the bottom of the hole, there is a sealing plate 103 that is limited in the height direction, and the sealing plate 103 can be rotated by the rotating mechanism to open the injection hole; the bottom of the push rod 102 has a pushing plate that matches the i...

Embodiment 2

[0074] housing, such as Figure 9As shown, it is a shell 501 with an open bottom made of refractory material, a connecting rod 502 made of refractory material is fixed on the top of the shell 501, and the release valve plate is detachably installed on the shell 501 The fusible plate 503 at the bottom, the release valve plate is an iron plate. The driving part is fixed to the connecting rod 502 at its lifting end. Such as Figure 7 and 8 As shown, the driving part can adopt the same form as that in the first embodiment, and use a screw rod and a nut to cooperate and drive to realize the lifting of the accommodating part. The driving part can also be driven in the form of hoisting, and the hoisting is fixed on the hoisting frame.

[0075] When the spheroidizing ladle 401 is filled with molten iron, the drive unit drives the housing 501 down into the bottom of the spheroidizing ladle 401. After a short time, the iron plate is melted by the molten iron, and the bottom of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com