A kind of reducing agent for dye and preparation method thereof

A reducing agent and dye technology, applied in the field of printing and dyeing, can solve problems such as unfavorable storage, easy heating, easy decomposition, etc., and achieve the effect of enhancing the ability of waterproof vapor penetration, prolonging storage time, and reducing the possibility of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

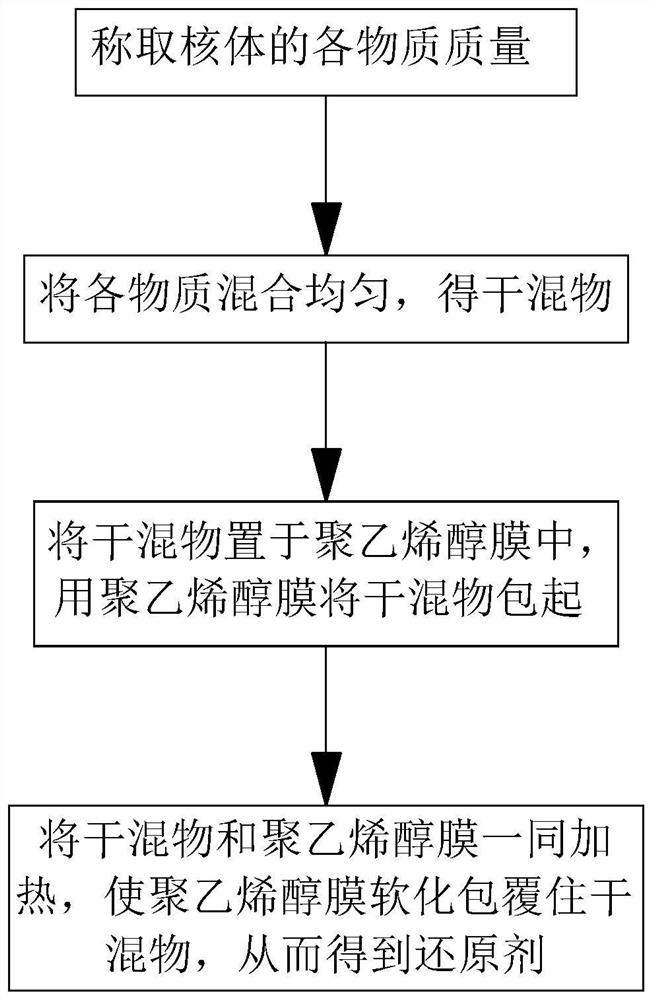

[0037] A method for preparing a reducing agent for dyes, comprising the steps of,

[0038] Step 1: each component of nucleosome is taken by weighing, be respectively 10g hydrosulfite, 8g thiourea dioxide and 7g sodium ascorbate;

[0039] Step 2: adding all the substances in step 1 into a dry blender for uniform mixing to obtain a dry blend;

[0040] Step 3: Place the dry mixture in a polyvinyl alcohol film with a thickness of 20um, and then wrap the dry mixture with the polyvinyl alcohol film;

[0041] Step 4: heating the polyvinyl alcohol film and the dry mixture together at a temperature of 120-140° C., so that the polyvinyl alcohol is softened and completely coated on the dry mixture, thereby obtaining a finished reducing agent with a core-shell structure.

[0042] Here, the degree of alcoholysis of polyvinyl alcohol is 65%, and the degree of polymerization is 1700-2600.

Embodiment 2

[0044] A method for preparing a reducing agent for dyes, comprising the steps of,

[0045] Step 1: take each component of nuclear body, be respectively 13g sodium bicarbonate, 16g thiourea dioxide and 10g sodium ascorbate;

[0046] Step 2: adding all the substances in step 1 into a dry blender for uniform mixing to obtain a dry blend;

[0047] Step 3: Place the dry mixture in a polyvinyl alcohol film with a thickness of 20um, and then wrap the dry mixture with the polyvinyl alcohol film;

[0048] Step 4: heating the polyvinyl alcohol film and the dry mixture together at a temperature of 120-140° C., so that the polyvinyl alcohol is softened and completely coated on the dry mixture, thereby obtaining a finished reducing agent with a core-shell structure.

[0049] Here, the degree of alcoholysis of polyvinyl alcohol is 75%, and the degree of polymerization is 1700-2600.

Embodiment 3

[0051] A method for preparing a reducing agent for dyes, comprising the steps of,

[0052] Step 1: take each component of nuclear body, be respectively 16g sodium bicarbonate, 24g thiourea dioxide and 13g sodium ascorbate;

[0053] Step 2: adding all the substances in step 1 into a dry blender for uniform mixing to obtain a dry blend;

[0054] Step 3: Place the dry mixture in a polyvinyl alcohol film with a thickness of 20um, and then wrap the dry mixture with the polyvinyl alcohol film;

[0055] Step 4: heating the polyvinyl alcohol film and the dry mixture together at a temperature of 120-140° C., so that the polyvinyl alcohol is softened and completely coated on the dry mixture, thereby obtaining a finished reducing agent with a core-shell structure.

[0056] Here, the degree of alcoholysis of polyvinyl alcohol is 85%, and the degree of polymerization is 1700-2600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com