Impermeable technology for ultra-large-caliber concrete rainwater pipeline joint

A pipeline interface and super-large diameter technology, which is applied in the field of anti-seepage technology for super-large diameter concrete rainwater pipeline interfaces, can solve problems such as hidden dangers of superstructure, loose foundation soil, sand loss, etc., and achieve the effects of convenient construction, low cost and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

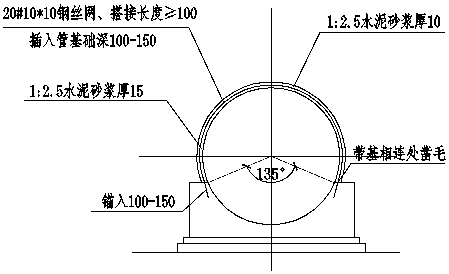

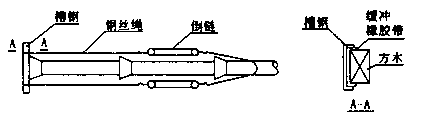

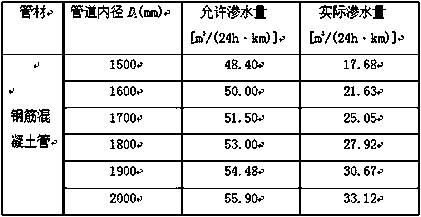

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0027] Taking Suzhou Port XX Port Area X Phase Project as an example, the main way of rainwater drainage is rainwater pipes. The clean rainwater in the storage yard is collected through open ditches and hidden pipes and then discharged into the rainwater pump room. It is discharged through gravity flow at low tide in the Yangtze River, and discharged through submersible axial flow pumps at high tide. Domestic sewage is collected through hidden pipes and lifted by sewage lift pumps. Then connect to the municipal sewage pipe network.

[0028] Installation process of super large concrete pipe joints

[0029] 1. Pipeline foundation

[0030] Pipe foundations include grav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com