A point source spacer support loss reduction method using the back bladder bag filling of the hydraulic support

A technology of hydraulic supports and bladders, which is applied in the direction of filling, earth square drilling, mining equipment, etc., can solve the problems of reducing the service life of mines, unsuitable for large-scale promotion and implementation of coal mine enterprises, and high cost investment, so as to achieve the realization of coal mining and The effect of supporting continuous operation, controlling uneven settlement of overlying rock, and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

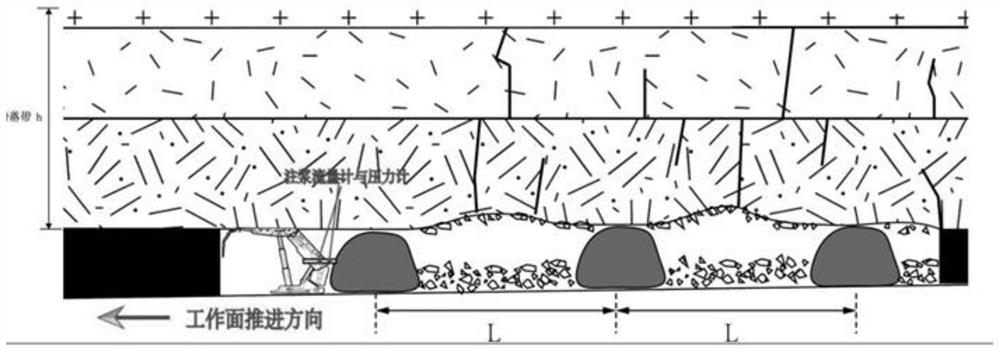

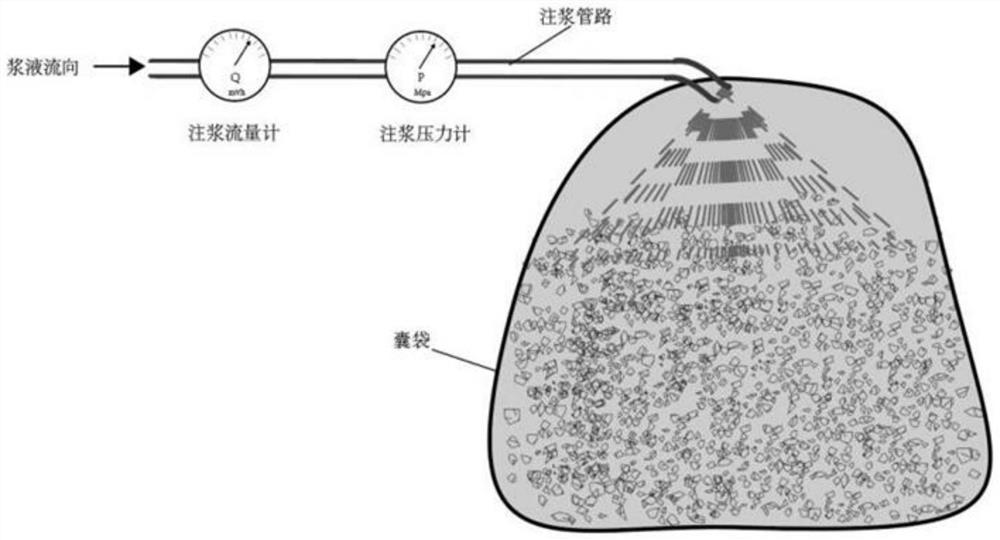

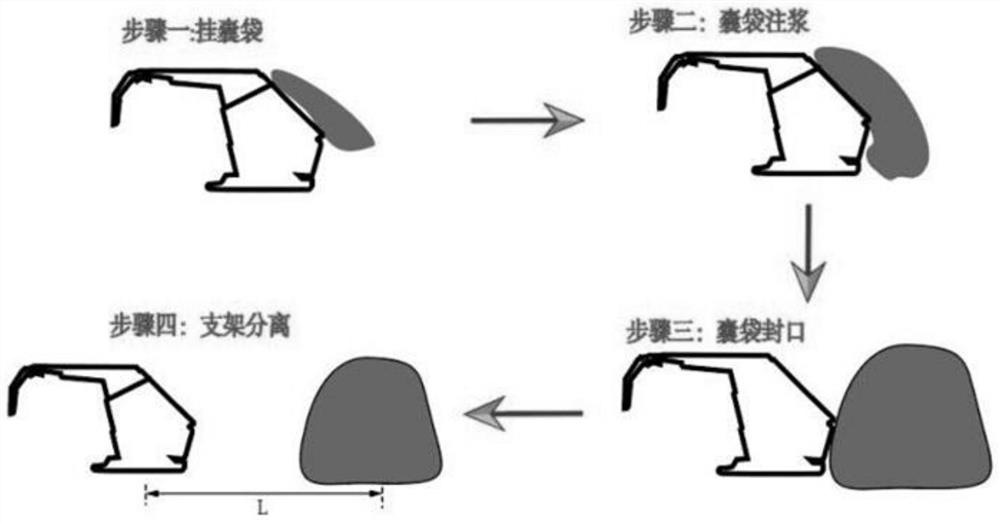

[0036] refer to Figure 1~5 , a method for reducing the damage of a point-source spacer support by filling the back capsule bag of a hydraulic support, specifically comprising the following steps:

[0037] The first step is to determine the overall height of the caving zone through the relationship between the mining height and the caving zone and the mining geological data of the actual coal mine, and determine the spacing L of the point-source spacer support body through the initial caving step distance of the direct top of the roof, and at the same time Considering a certain safety reserve factor, the relationship between mining height and caving zone in this step is a common or easy-to-measure parameter in geological mining;

[0038] The second step is to refer to the relevant national standards for performance testing of grouting materials in coal mines, and determine the appropriate grouting material mix ratio, initial setting time, and grouting strength based on laborat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com