Modular redundancy electromechanical actuators capable of being connected in series and in parallel

An electromechanical actuator and modularization technology, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problem that a single electromechanical actuator is too bulky to realize modularization, and electromechanical actuators cannot be freely combined according to requirements. , the limited degree of power superposition, etc., to reduce power, save installation space, and solve the effect of small stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

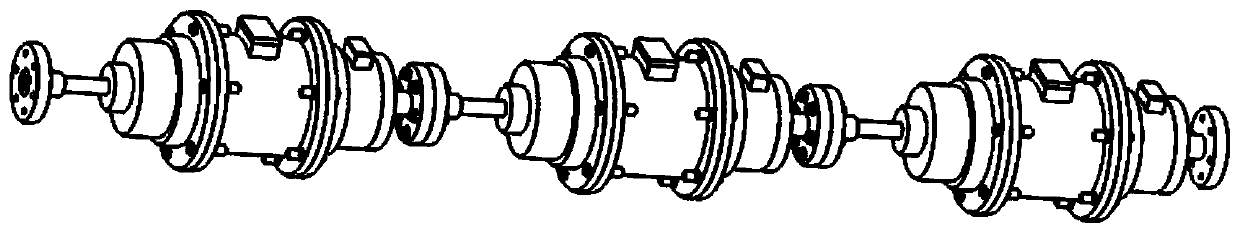

[0022] This embodiment is a modular redundant electromechanical actuator that can be connected in series and parallel.

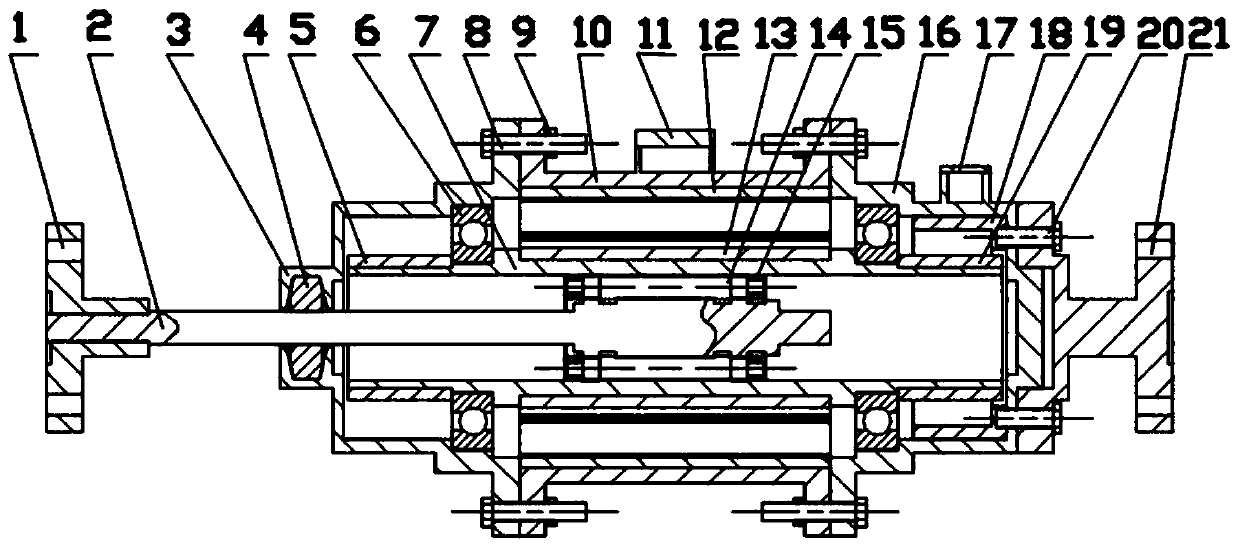

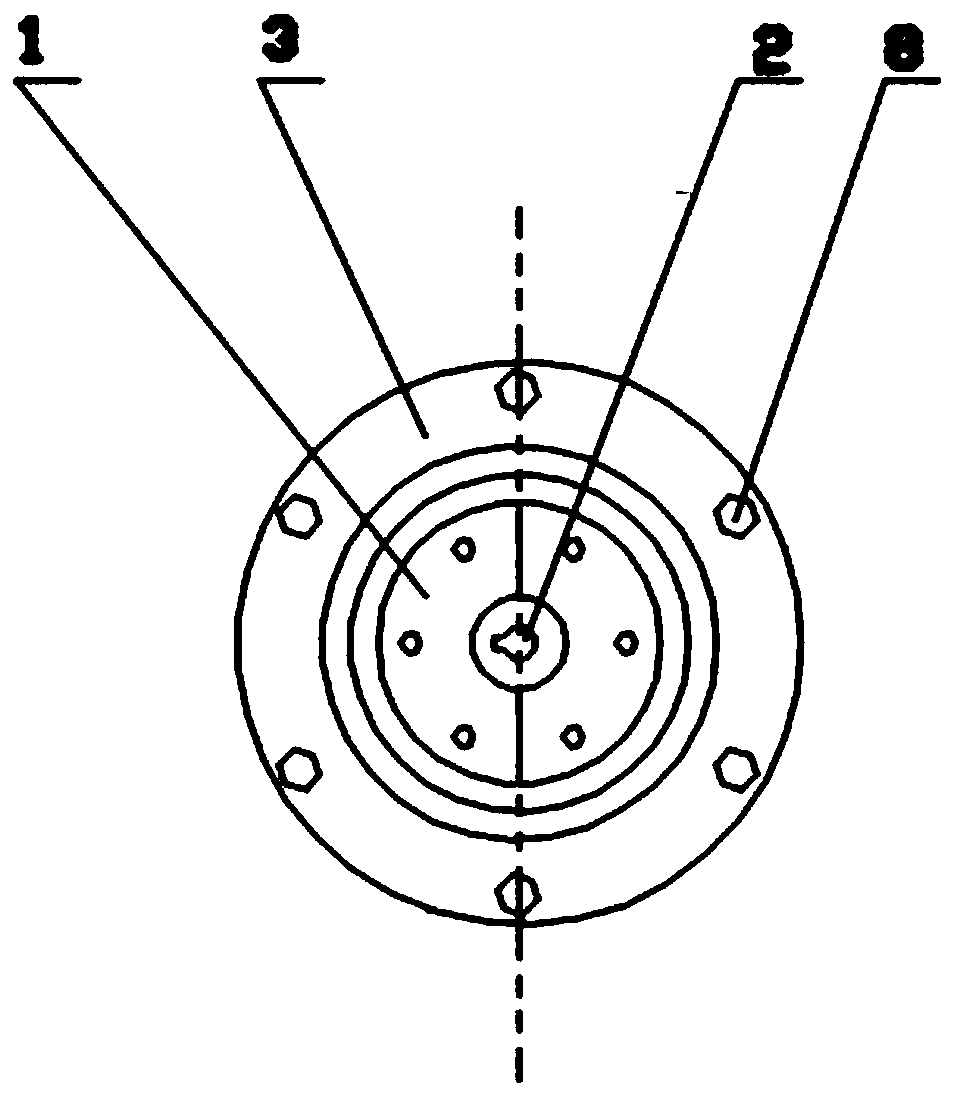

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , the modular redundant electromechanical actuator that can be connected in series and parallel in this embodiment is composed of a coupling 1, a first end cover 3, a felt ring 4, a sleeve 5, a deep groove ball bearing 6, a bolt 8, a hex nut 9, Housing 10, junction box 11, second end cover 16, screw 20, push plate 21, parallel device 22, motor, actuator and limit sensing mechanism; multiple electromechanical actuators are used in series or in parallel configuration to The electromechanical actuator is a unit, and the planetary roller screw pair is used as an actuator; wherein, the actuator includes a screw 2, a rotor 13, a roller 14, a cage 15, and a nut 7, and one end of the screw 2 is fixed with a coupling 1. Even, the other end of the lead screw 2 passes through the first end cover 3, the fel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com