Road crossing sleeve penetrating leading-in vehicle for buried pipeline and using method thereof

A casing and pipe technology, which is applied in the field of introduction vehicles for casing pipe penetration in buried pipelines, can solve problems such as damage to the anticorrosion layer on the surface of buried pipes, reduce repair costs, reduce construction costs, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below with reference to accompanying drawing and embodiment:

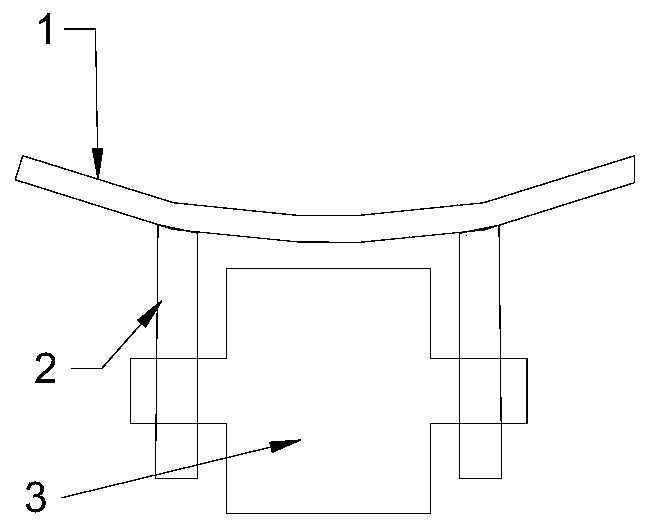

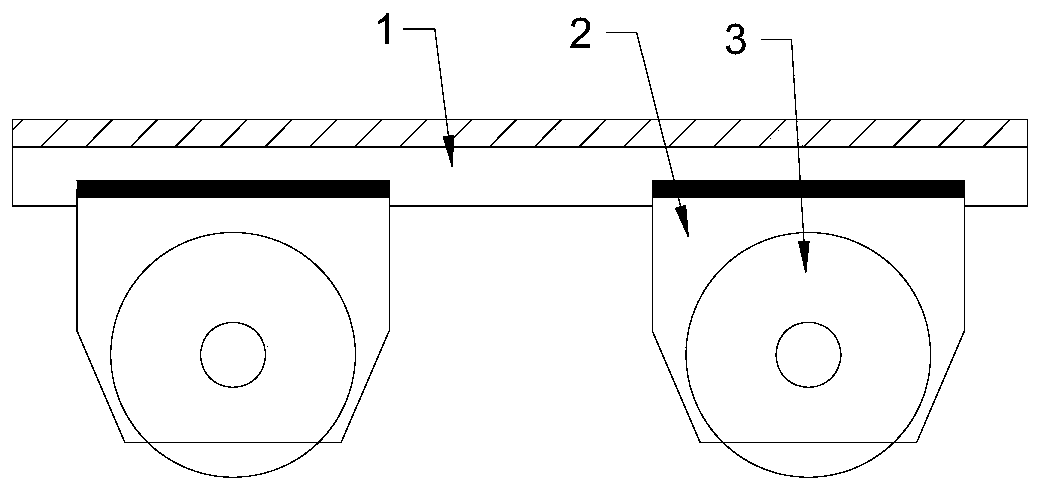

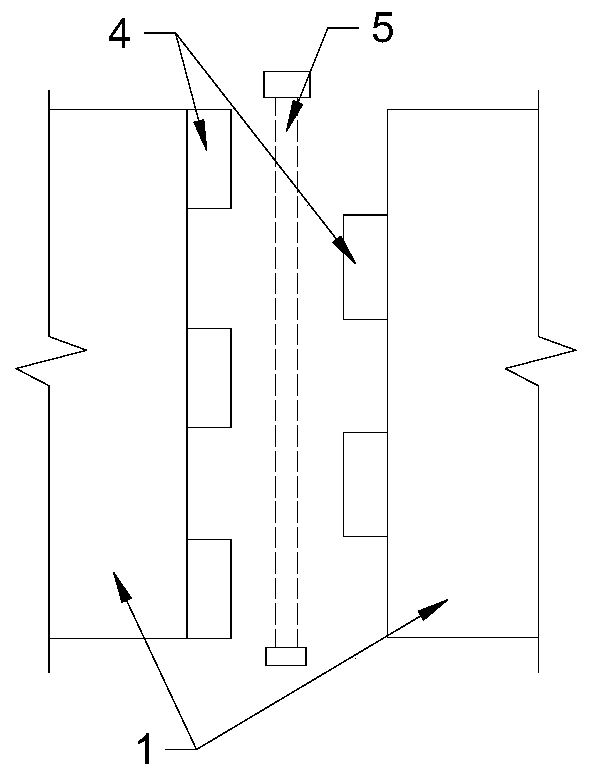

[0022] Such as Figure 1-5 The shown one kind of underground pipeline passage casing piercing pipe introduction vehicle includes three arc-shaped pallets 1, and each arc-shaped pallet 1 is provided with a roller shaft 3 at the front and rear, and the rollers of the roller shafts 3 The diameter of the body is 50 mm, with shaft ends on both sides, and the shaft ends are installed in the ear plate 2, and the ear plate 2 is fixedly connected to the outer side of the arc surface of the arc-shaped supporting plate 1; the two sides of the arc-shaped supporting plate 1 are fixedly connected to the shaft tube 4, The sides of three arc-shaped supporting plates 1 are connected with each other in turn to form a large arc-shaped plate. The shaft tubes 4 of two adjacent arc-shaped supporting plates 1 are arranged alternately, and the shaft tubes 4 are pierced with pin shafts 5;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com