Drying and purifying process and device based on four towers

A purification device and drying technology, applied in the field of drying, purification process and device based on four towers, can solve the problem of high energy consumption of equipment and achieve the effect of good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

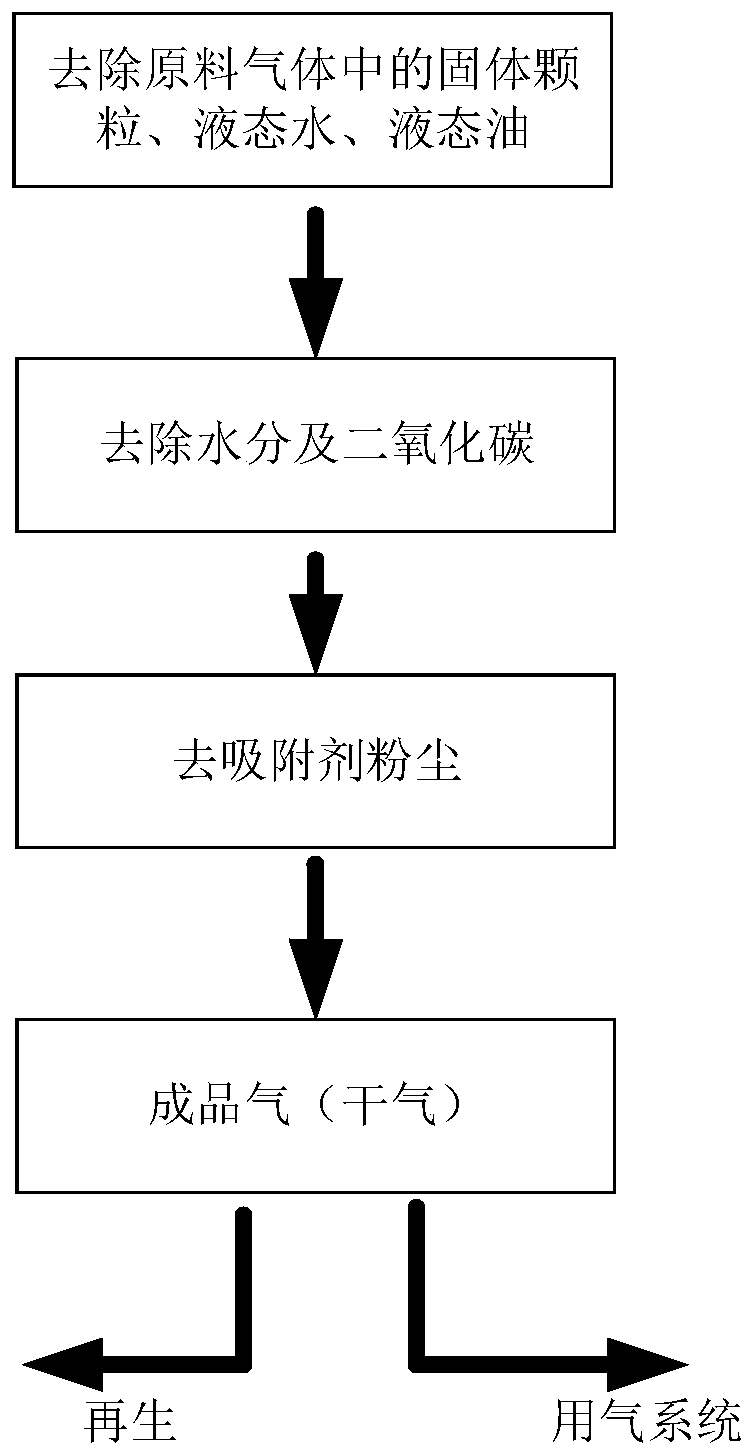

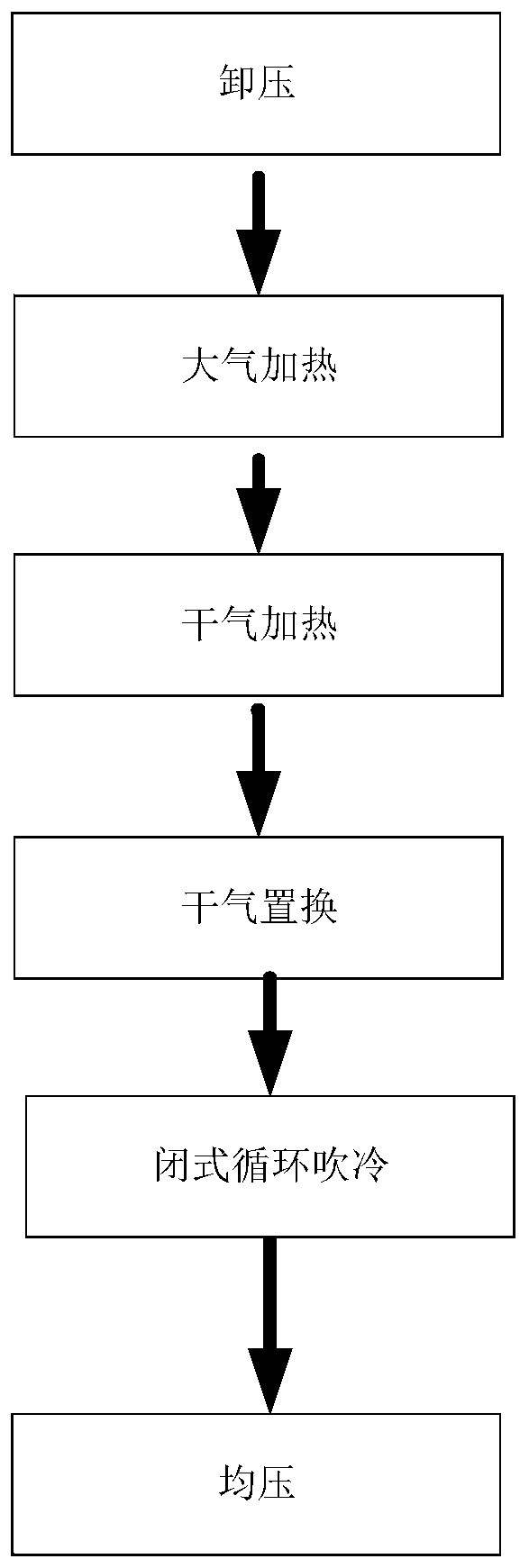

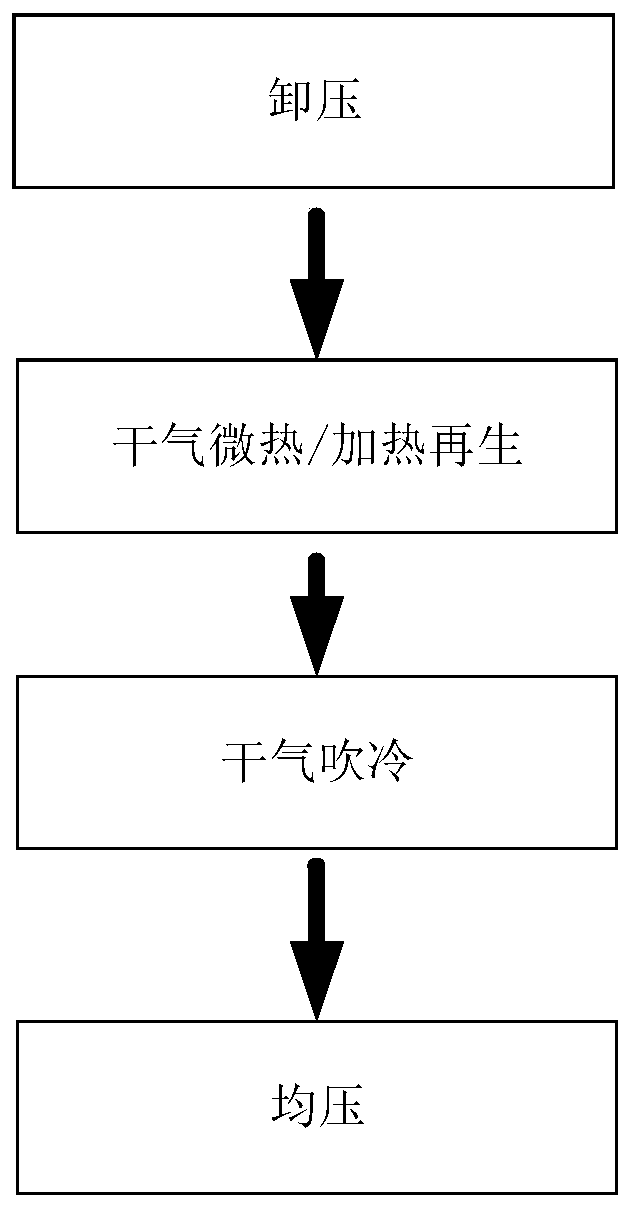

[0079] Such as Figure 1-3 As shown, the drying and purification process based on four towers provided in this embodiment comprises the following steps:

[0080] 1] Utilize the drying and purification towers A1 and A2 to simultaneously absorb and purify, and the drying and purification towers B1 and B2 to regenerate separately

[0081] 1.1] Adsorption purification

[0082] 1.1.1] Separating and filtering the solid particles and liquid water contained in the raw gas;

[0083] 1.1.2] The gas obtained after the treatment in step 1.1.1] first flows through the drying and purification tower A1 loaded with the first adsorbent for adsorption drying and purification, removes moisture and part of the impurity gas in the gas, and then flows through the drying and purification tower A1 loaded with the first adsorbent The drying and purification tower A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com