Automatic feeding and automatic turning-round magnetic material punching machine

A technology of magnetic materials and drilling machines, applied in boring/drilling, drilling/drilling equipment, metal processing, etc., can solve the problems of high labor costs, increased defect rate, low processing accuracy, etc., to reduce labor The effect of time and labor intensity, avoiding product missing corners, and avoiding loss of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

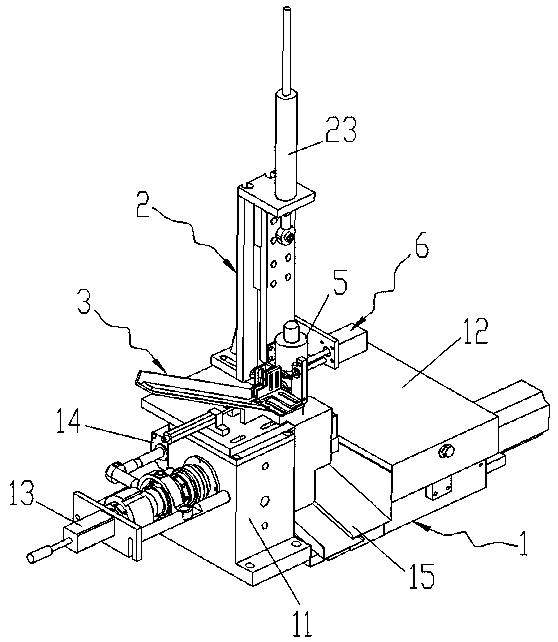

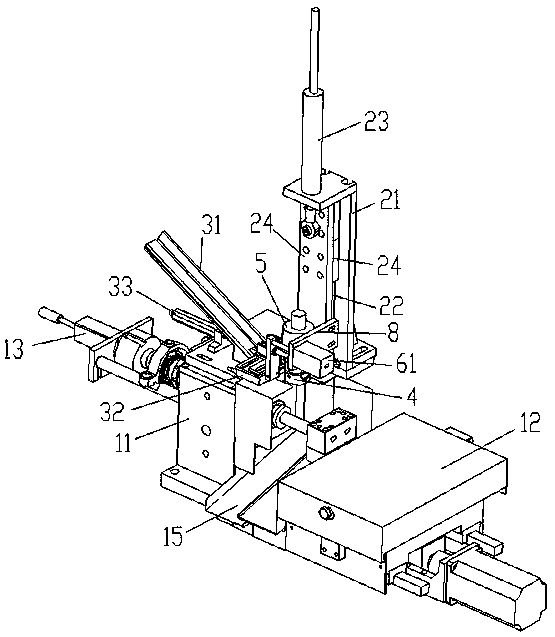

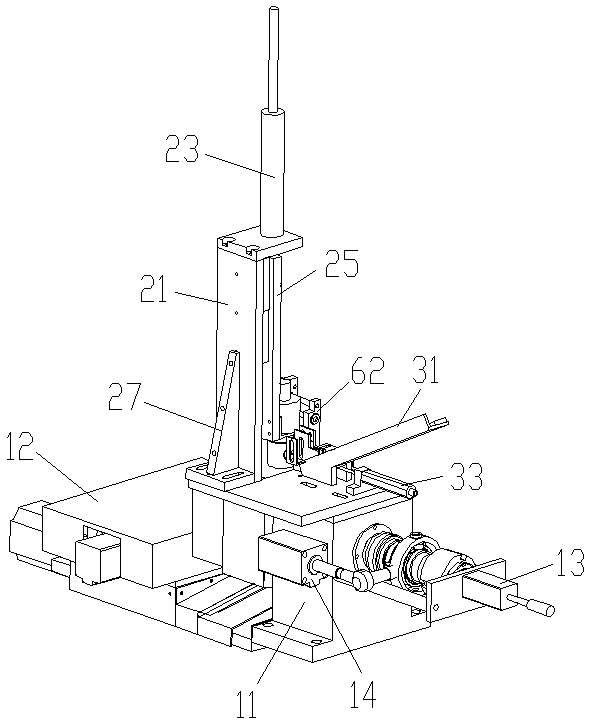

[0037] Figures 1 to 10 It is a structural representation of the present invention.

[0038] The reference signs are: control cabinet G, punching machine main body 1, clamping workpiece and rotating spindle device 11, cross table 12, material return cylinder 13, clamping cylinder 14, material storage tank 15, lifting device 2, Lifting bracket 21, lifting guide rail 22, lifting cylinder 23, guide rail slider 24, lifting slide plate 25, pin shaft 26, reinforcement plate 27, automatic feeding device 3, feeding guide rail 31, feeding chute 31a, guide rail base 32, Feeding port 32a, feeding cylinder 33, feeding cylinder bracket 34, rotating manipulator 4, receiving hole 4a, cutout 4b, concave surface 4c, connecting sleeve 41, rotator 5, rotator bracket 51, ejector device 6, Material jacking cylinder 61, material jacking connecting plate 62, materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com