Security door panel intelligent batching tower warehouse

A technology of intelligent batching and anti-theft doors, applied in transportation, packaging, storage devices, etc., can solve the problems of occupied space, low degree of automation, and high labor costs, and achieve the effects of safe and reliable production, simple and convenient transshipment, and convenient on-site management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

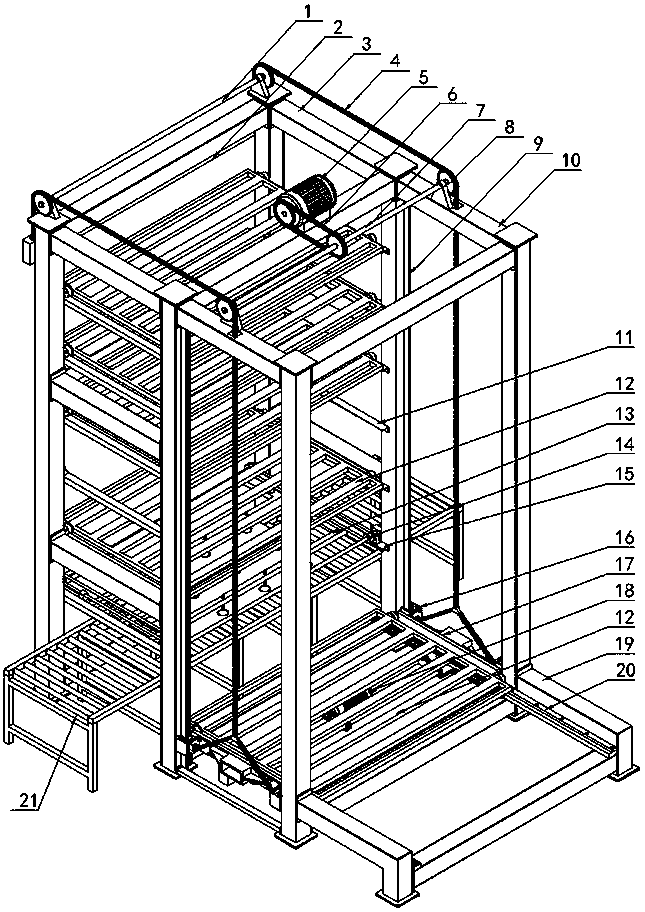

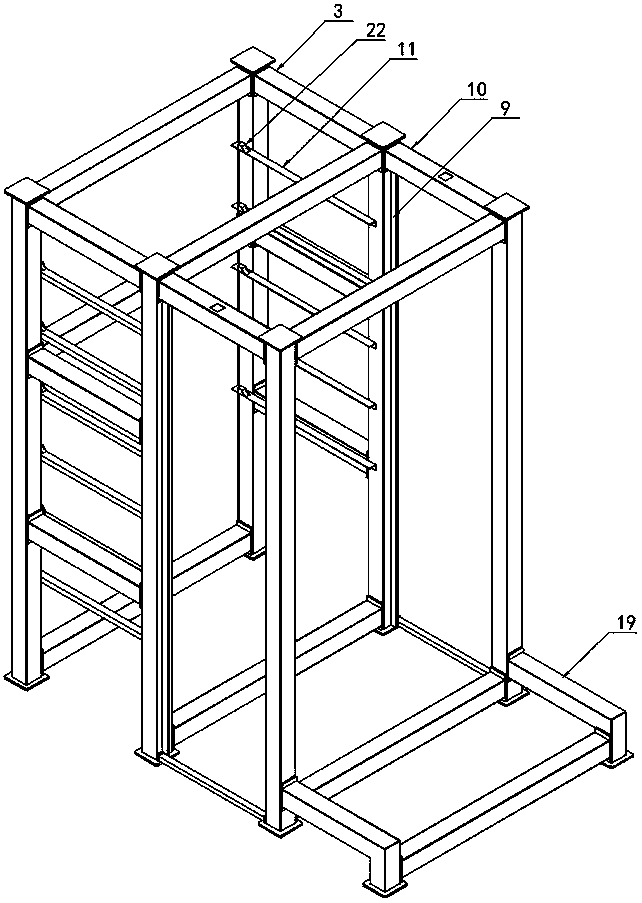

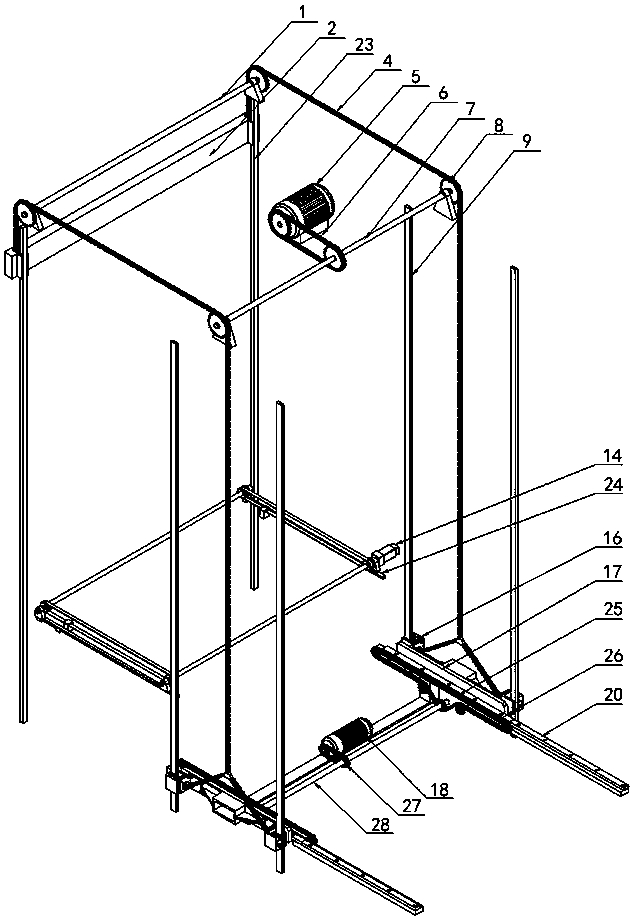

[0020] Figure 1 to Figure 6 Shown, for the present invention creates the specific embodiment of anti-theft door panel intelligent batching tower storehouse, it comprises the material storage tower frame 3 and lifting support 10 of fixing one, storage material trolley 12, transshipment mechanism, lifting mechanism, described material storage The tower frame 3 is provided with several layers of batching racks 11 for placing material storage trolleys 12 and a grabbing mechanism 14 located below the bottom batching rack 11. The slide rail seat 15, the slide rail 24 correspondingly fixed below the slide rail seat 15, the fourth roller shaft 30 and the fifth roller shaft 31 which are rotatably arranged on the front and back of the left and right sides of the slide rail seat 15 and located above, correspondingly fixed The synchronous pulley 40 at both ends of the fourth roller shaft 30 and the fifth roller shaft 31, the synchronous belt 32 correspondingly connected between the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com