Fireproof and thermal insulation curtain wall and its manufacturing method

A technology for fire prevention and heat preservation and manufacturing method, applied in fire prevention, heat preservation, wall and other directions, can solve problems such as easy generation of toxic substances, technical problems of cold and hot bridges, lack of fire prevention function, etc., to achieve overall quality assurance, reduce comprehensive costs, The effect of improving the thermal insulation effect and the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

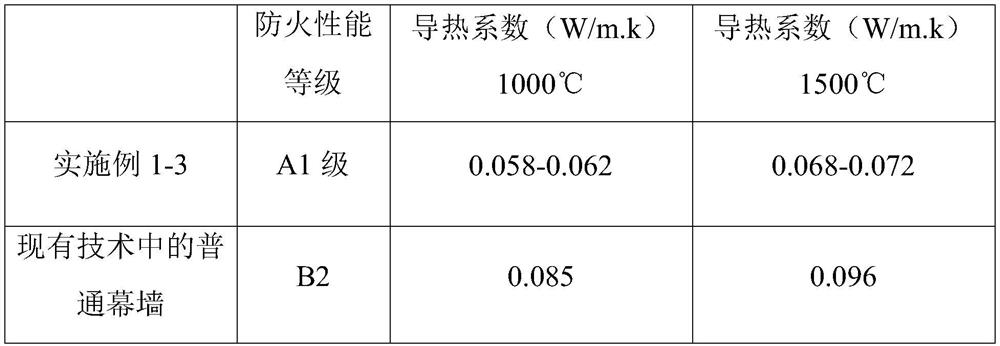

Embodiment 1

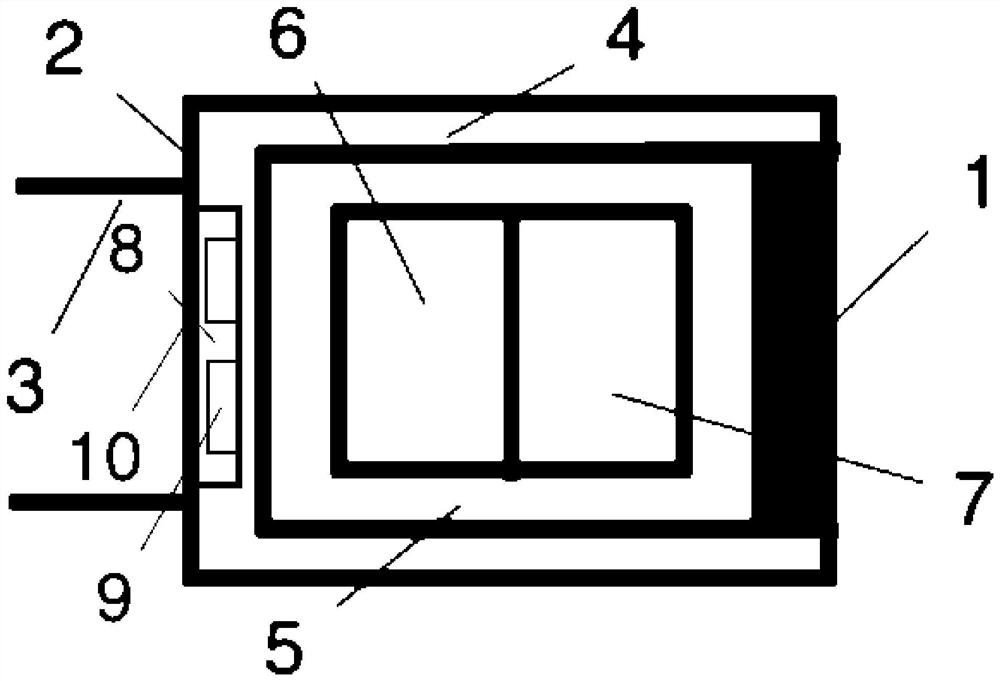

[0034]A fire insulation curtain wall, including a curtain wall layer 1, a curtain wall core block 2, and a connecting member 3; the wall layer 1 is fixed within the outer fire layer 4 of the curtain wall core block 2, and the curtain core block 2 passes the The connector 3 is fixed to the wall;

[0035]The curtain wall core block 2 includes an outer fire layer 4 and an inner fire layer 5, which is in the form of a closed square, and the first insulation layer 6 and the second heat preservation are disposed vertically side vertically. Layer 7; the outer fire layer 4 is provided with a groove 8 on the outer surface of the wall, and a plurality of automatic spraying apparatus 9 are provided in the groove 8, and the groove 8 is covered with a protective film 10, The protective film 10 is a low melting film;

[0036]The outer fire layer 4 includes a weight of the following weight: PC plastic resin 30-35, diatomaceous earth 20-25, nano-aluminum acid 15-20, vermiculum powder 15-20, calcination 5...

Embodiment 2

[0054]A fire insulation curtain wall, including a curtain wall layer 1, a curtain wall core block 2, and a connecting member 3; the wall layer 1 is fixed within the outer fire layer 4 of the curtain wall core block 2, and the curtain core block 2 passes the The connector 3 is fixed to the wall;

[0055]The curtain wall core block 2 includes an outer fire layer 4 and an inner fire layer 5, which is in the form of a closed square, and the first insulation layer 6 and the second heat preservation are disposed vertically side vertically. Layer 7; the outer fire layer 4 is provided with a groove 8 on the outer surface of the wall, and a plurality of automatic spraying apparatus 9 are provided in the groove 8, and the groove 8 is covered with a protective film 10, The protective film 10 is a low melting film;

[0056]The outer fire layer 4 includes a weight of the following weight: PC plastic resin 30-35, diatomaceous earth 20-25, nano-aluminum acid 15-20, vermiculum powder 15-20, calcination 5...

Embodiment 3

[0077]A fire insulation curtain wall, including a curtain wall layer 1, a curtain wall core block 2, and a connecting member 3; the wall layer 1 is fixed within the outer fire layer 4 of the curtain wall core block 2, and the curtain core block 2 passes the The connector 3 is fixed to the wall;

[0078]The curtain wall core block 2 includes an outer fire layer 4 and an inner fire layer 5, which is in the form of a closed square, and the first insulation layer 6 and the second heat preservation are disposed vertically side vertically. Layer 7; the outer fire layer 4 is provided with a groove 8 on the outer surface of the wall, and a plurality of automatic spraying apparatus 9 are provided in the groove 8, and the groove 8 is covered with a protective film 10, The protective film 10 is a low melting film;

[0079]The outer fire layer 4 includes a weight of the following weight: PC plastic resin 30-35, diatomaceous earth 20-25, nano-aluminum acid 15-20, vermiculum powder 15-20, calcination 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com