Land slurry lifting experimental platform for deep-sea mining

A deep-sea mining and experimental platform technology, applied in mining minerals, special mining, earth cube drilling and mining, etc., can solve problems such as low efficiency and unreliable reliability, and achieve the effects of fast switching, low production cost, and high degree of operation automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

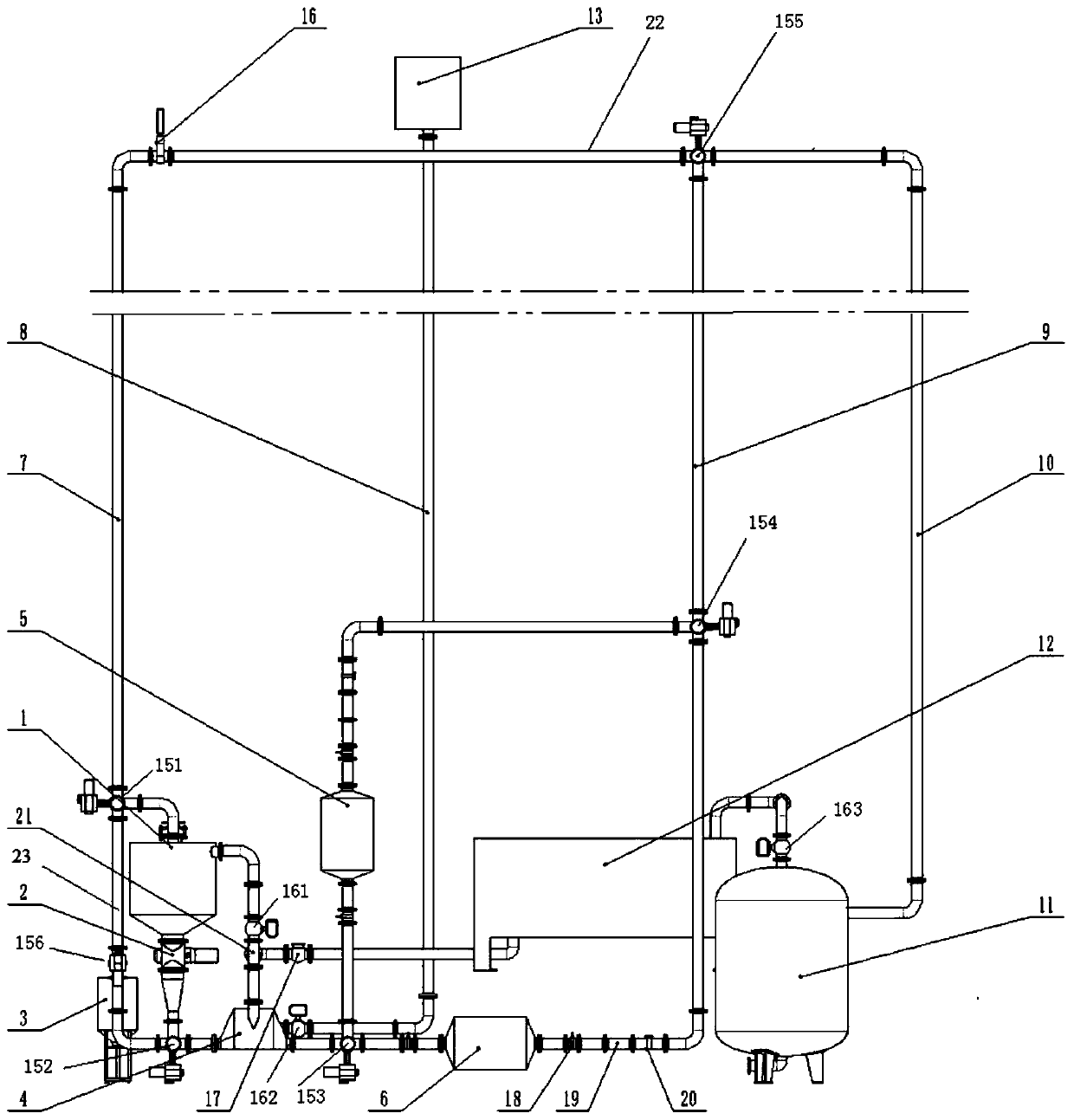

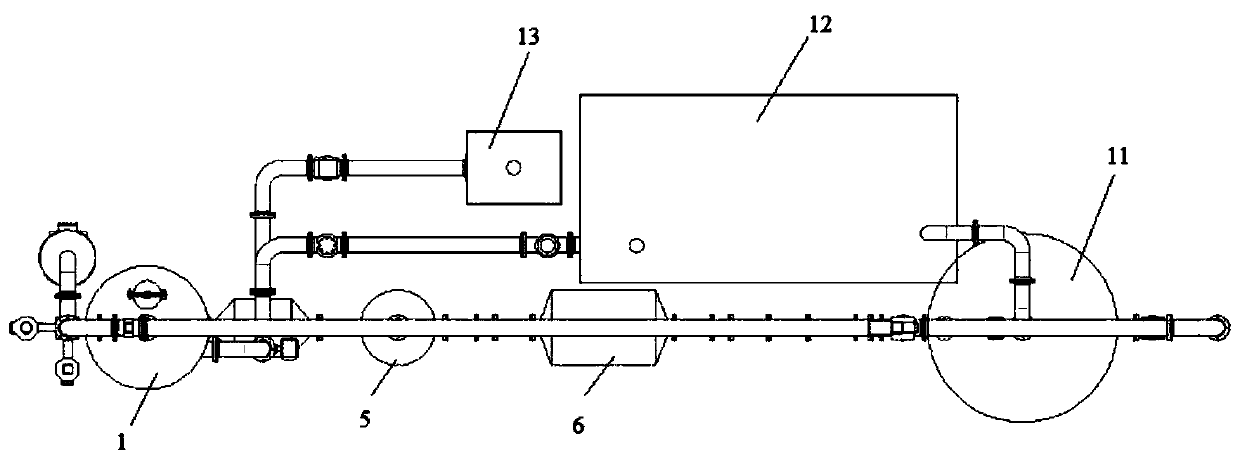

[0038] Embodiment 1, a kind of deep-sea mining land slurry lifting experiment platform, such as figure 1 and figure 2 As shown, it includes a silo 1, and the bottom of the silo 1 is provided with a blanking machine 2; the silo 1 is a closed silo, and a quick-opening feeding port is provided.

[0039] The downward conveying pipe 7, the lower connecting pipe 23 and the silo 1 are respectively connected with the three-way valve I151, that is, the silo 1 is connected with the downward conveying pipe 7 in a bypass form through the three-way valve I151; the lower connecting pipe 23 is connected through the three-way valve I151. After Ⅵ156, it is divided into two paths, one path is connected to the measuring device 3, and the other path is connected to the outlet of the blanking machine 2 through the three-way valve Ⅱ152 and then connected to the water bag 4;

[0040] The effect of measuring device 3 is to measure the volume concentration of particulate matter (coarse ore solid par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com