Aspalathus linearis substitute tea and making method thereof

A technology of gorse line leaf and substitute tea, applied in the field of tea beverage processing, can solve the problems of insignificant efficacy, unclear safety, and weak universality, etc., and achieves the effect of promoting cardiovascular health, relieving tension and excellent taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

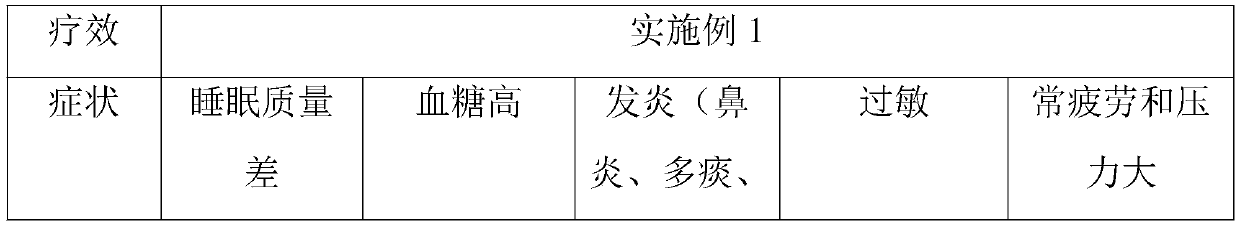

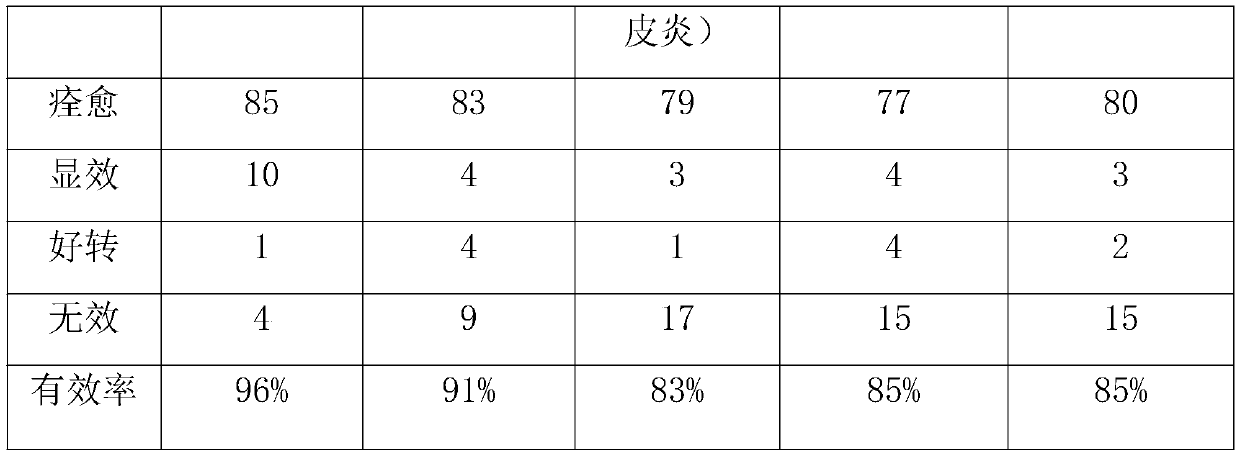

Examples

Embodiment 1

[0031] The invention relates to a substitute tea of gorse twig, which comprises the following raw material components in parts by weight: 35 parts of gorse twig, 10 parts of medlar, 10 parts of sealwort, 10 parts of poria cocos and 10 parts of raspberry.

[0032] The preparation method of described line leaf gorse substitute tea, the steps are as follows:

[0033] S1. Sorting and cleaning: pick out the impurities in wolfberry fruit, sealwort, poria cocos and raspberry, and clean them to obtain cleaned raw materials;

[0034] S2. Drying: drying the cleaned raw materials to obtain dried raw materials;

[0035] S3. Crushing: pulverize the dried raw materials to obtain raw material granules, and add gorse line leaves and mix evenly therein;

[0036] S4. Packaging: Nitrogen flushing packaging.

[0037] Wherein, the drying condition described in step S2 is 50° C. for 50 minutes.

[0038] The raw material particles described in step S3 have a size of 12 mesh.

[0039] The line-...

Embodiment 2

[0041] The invention relates to a substitute tea of gorse twig, which comprises the following raw material components in parts by weight: 50 parts of gorse twig, 10 parts of medlar, 10 parts of sealwort, 10 parts of poria cocos and 10 parts of raspberry.

[0042] The preparation method of described line leaf gorse substitute tea, the steps are as follows:

[0043] S1. Sorting and cleaning: pick out the impurities in wolfberry fruit, sealwort, poria cocos and raspberry, and clean them to obtain cleaned raw materials;

[0044] S2. Drying: drying the cleaned raw materials to obtain dried raw materials;

[0045] S3. Crushing: pulverize the dried raw materials to obtain raw material granules, and add gorse line leaves and mix evenly therein;

[0046] S4. Packaging: Nitrogen flushing packaging.

[0047] Wherein, the drying condition described in step S2 is 50° C. for 50 minutes.

[0048] The raw material particles described in step S3 have a size of 12 mesh.

[0049] The subst...

Embodiment 3

[0051] The invention relates to a substitute tea of gorse twig, which comprises the following raw material components in parts by weight: 35 parts of gorse twig, 30 parts of medlar, 10 parts of sealwort, 10 parts of poria cocos and 10 parts of raspberry.

[0052] The preparation method of described line leaf gorse substitute tea, the steps are as follows:

[0053] S1. Sorting and cleaning: pick out the impurities in wolfberry fruit, sealwort, poria cocos and raspberry, and clean them to obtain cleaned raw materials;

[0054] S2. Drying: drying the cleaned raw materials to obtain dried raw materials;

[0055] S3. Crushing: pulverize the dried raw materials to obtain raw material granules, and add gorse line leaves and mix evenly therein;

[0056] S4. Packaging: Nitrogen flushing packaging.

[0057] Wherein, the drying condition described in step S2 is 50° C. for 50 minutes.

[0058] The raw material particles described in step S3 have a size of 12 mesh.

[0059] The Gorse F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com