Synthesis process of ionic membrane

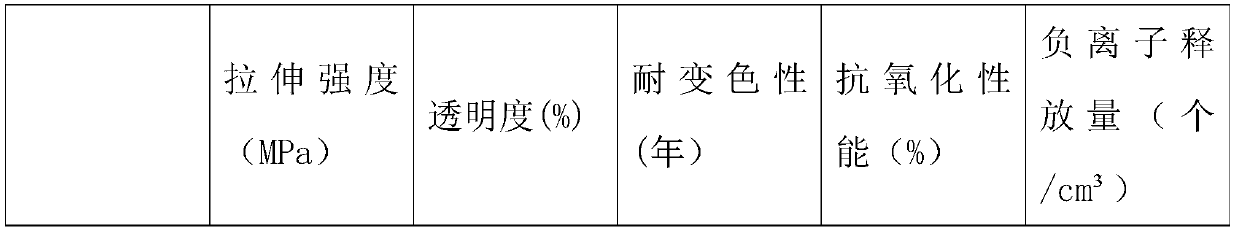

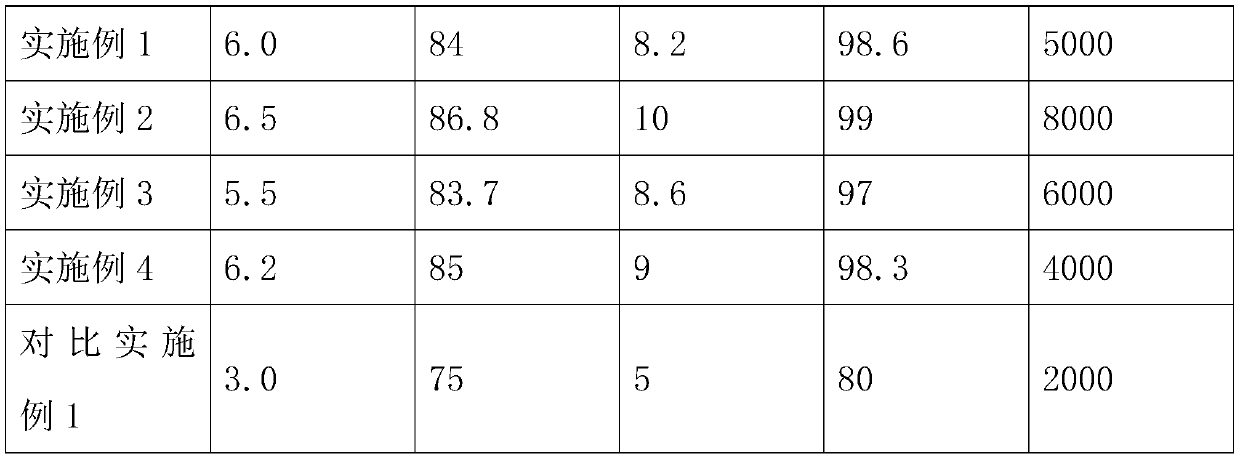

A synthesis process and ionic membrane technology, applied in the field of ionic membrane production, can solve problems such as limited coverage, easy yellowing and discoloration, poor toughness of ionic membranes, etc., achieve good tensile strength and oxidation resistance, and are not easy to yellow Effect of discoloration and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A synthesis process of an ionic membrane, the synthesis process included in the ionic membrane is the following steps: first put 10 parts of vermiculite powder, 5 parts of strange ice stone powder, 10 parts of tourmaline powder and 15 parts of deionized water into a mixing tank for mixing treatment , and add 20 parts of adhesive, and stir for 40 minutes to obtain a mixed solution; then add 5 parts of flame retardant, 0.5 part of antistatic agent, 0.5 part of anti-ultraviolet agent, and 2 parts of antioxidant into the mixed solution in order to carry out uniform stirring, and keep the temperature At 80°C, the rotation speed is kept at 1000r / min. After fully stirring, add 5 parts of perfluorosulfonic acid resin, 1 part of surfactant, 1 part of silane coupling agent and 2.5 parts of modifier to the mixed solution in sequence, and continue Stir for 50 minutes to prepare the film liquid; further, evenly coat the prepared film liquid on the bearing base layer, then put the bea...

Embodiment 2

[0024] A synthesis process of an ionic membrane, the synthesis process included in the ionic membrane is the following steps: first put 30 parts of vermiculite powder, 15 parts of strange ice stone powder, 20 parts of tourmaline powder and 30 parts of deionized water into a mixing tank for mixing treatment , and add 25 parts of adhesive, fully stir for 60 minutes to get the mixed solution; then add 10 parts of flame retardant, 2 parts of antistatic agent, 1.5 parts of anti-ultraviolet agent, and 4 parts of antioxidant into the mixed solution in order to carry out uniform stirring, and keep the temperature At 100°C, the rotation speed is kept at 2000r / min. After fully stirring, 10 parts of perfluorosulfonic acid resin, 3 parts of surfactant, 3 parts of silane coupling agent and 3.5 parts of modifier are sequentially added to the mixture, and continue Stir for 70 minutes to prepare the film liquid; further, evenly coat the prepared film liquid on the bearing base layer, then put ...

Embodiment 3

[0026] A synthesis process of an ionic membrane, the synthesis process included in the ionic membrane is the following steps: first put 20 parts of vermiculite powder, 12 parts of strange ice stone powder, 14 parts of tourmaline powder and 25 parts of deionized water into a mixing tank for mixing treatment , and add 22 parts of adhesive, fully stir for 50min to get the mixed solution; then add 7 parts of flame retardant, 1 part of antistatic agent, 0.8 parts of anti-ultraviolet agent, and 3 parts of antioxidant into the mixed solution for uniform stirring, and keep the temperature At 90°C, the rotation speed is kept at 1500r / min. After fully stirring, add 8 parts of perfluorosulfonic acid resin, 2 parts of surfactant, 1.5 parts of silane coupling agent and 3 parts of modifier to the mixed solution in sequence, and continue Stir for 60 minutes to prepare the film liquid; further, evenly coat the prepared film liquid on the bearing base layer, then put the bearing base layer into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com