Multifunctional block building assembly construction floor combined leveling device and method

A multifunctional and combined technology, applied in construction, measuring devices, building structures, etc., can solve problems such as complex leveling operations, poor assembly effects, and large leveling errors, and achieve increased clarity, standardized laying, and reduced brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

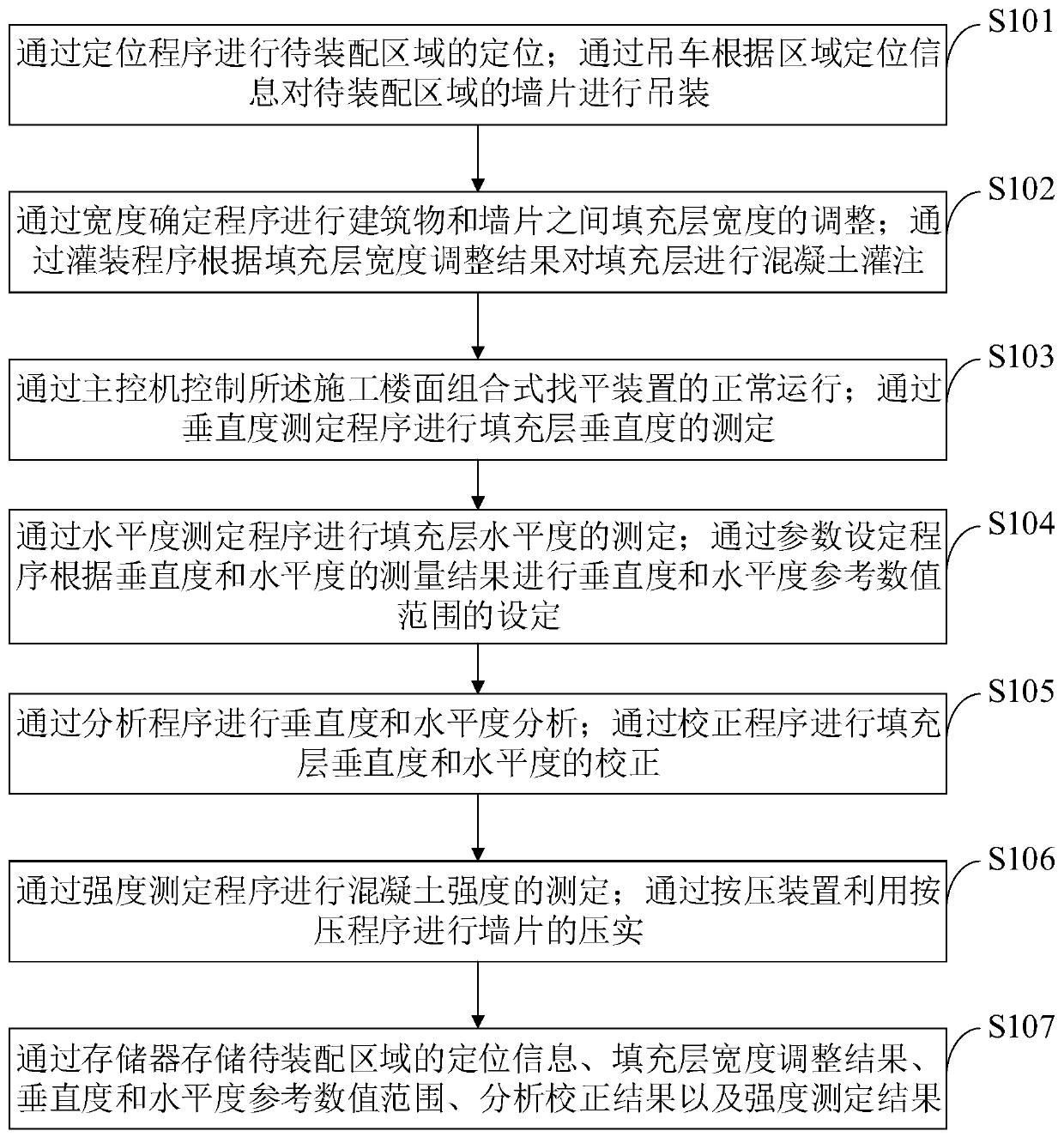

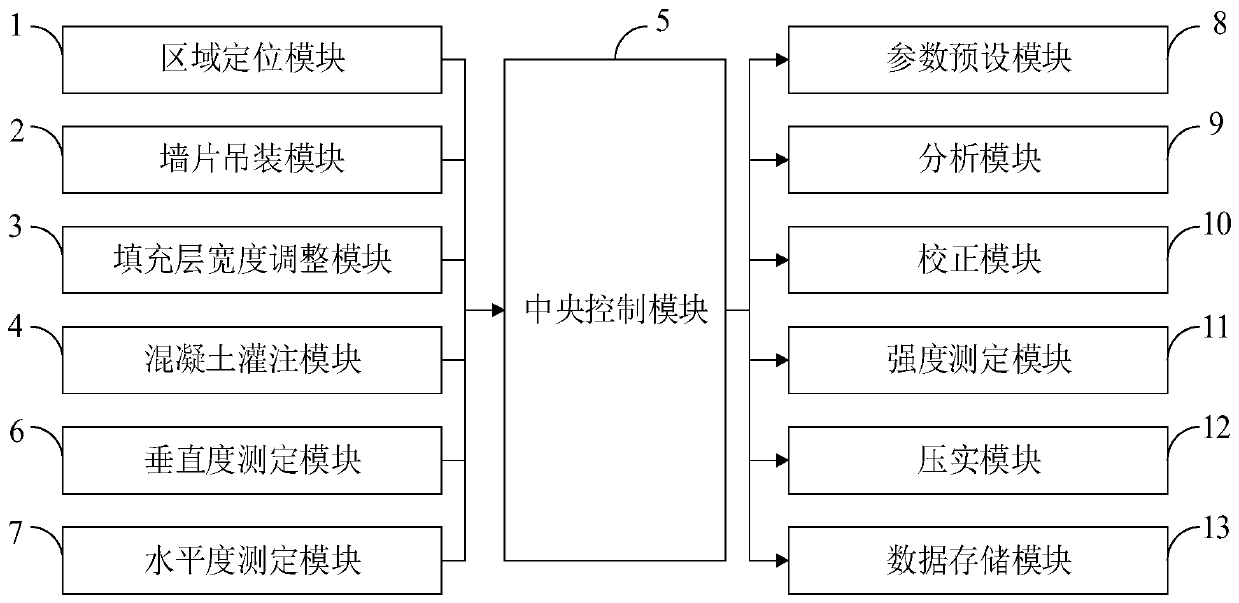

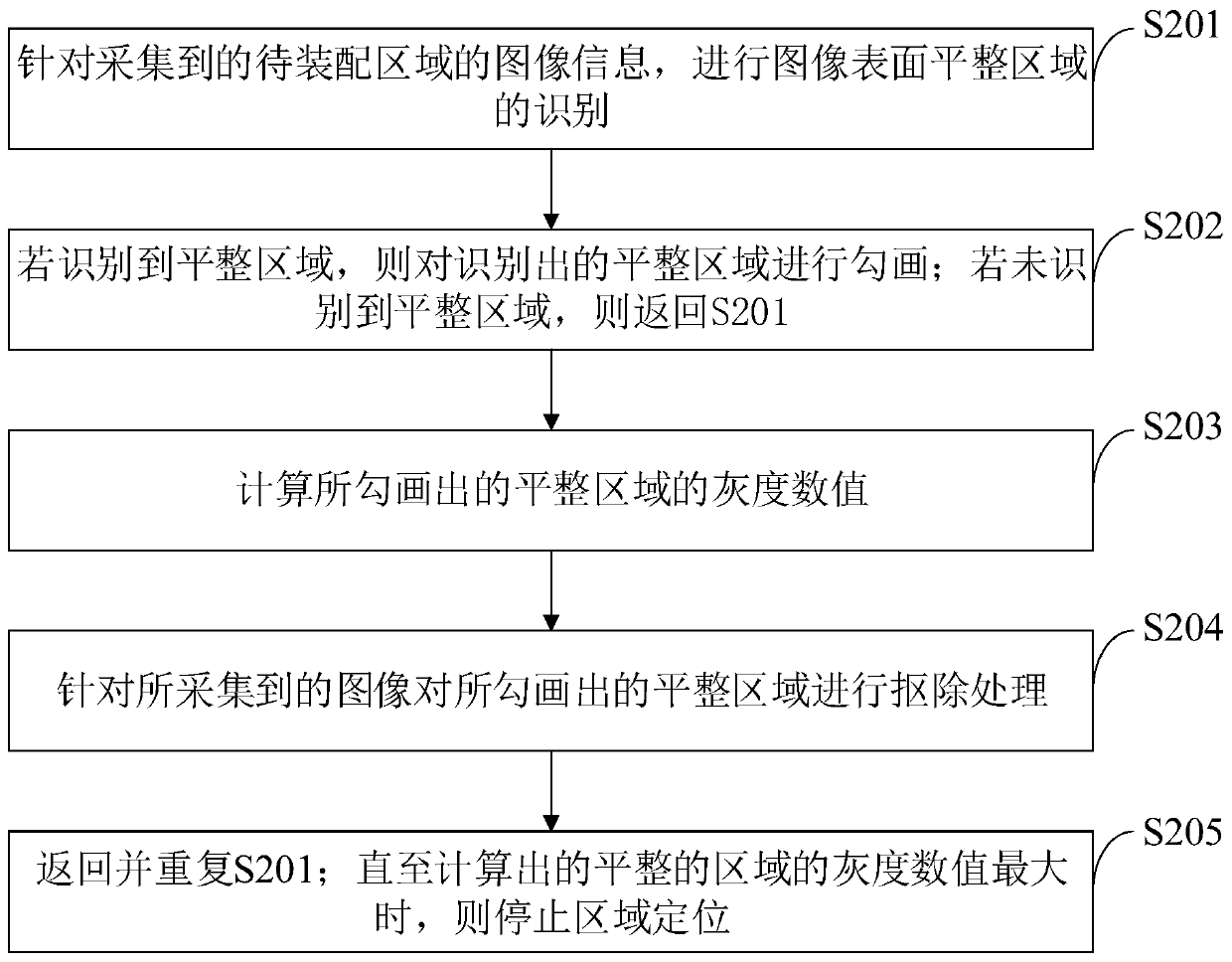

[0086] The method for leveling and leveling the assembled construction floor of the multi-functional cluster building provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as image 3 As shown, the positioning method of the area to be assembled provided by the embodiment of the present invention includes the following steps:

[0087] S201, according to the collected image information of the area to be assembled, identify the flat area of the image surface.

[0088] S202. If a flat area is identified, outline the identified flat area; if no flat area is identified, return to S201.

[0089] S203. Calculate the grayscale value of the outlined flat area.

[0090] S204, performing cutout processing on the outlined flat area for the collected image.

[0091] S205, return and repeat S201; until the calculated gray value of the flat area is the largest, stop area positioning.

[0092] The method for calculating the...

Embodiment 2

[0100] The method for leveling and leveling the assembled construction floor of the multi-functional cluster building provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as Figure 4 Shown, the method for verticality and levelness analysis that the embodiment of the present invention provides is:

[0101] S301. Acquire horizontal and vertical images of the filling layer, which are respectively a first image and a second image; the first image and the second image have different weights for different compositions of the target object.

[0102] S302. Process the first image and the second image respectively to obtain corresponding first parameters and second parameters; output feature points of the first parameters and the second parameters.

[0103] S303. Select two feature points from the image based on the output feature point information.

[0104] S304. Obtain deviation information between the first image a...

Embodiment 3

[0111] The method for leveling and leveling the assembled construction floor of the multi-functional cluster building provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as Figure 5 As shown, the correction method of the filling layer verticality and levelness provided by the embodiment of the present invention is:

[0112] S401. According to ranging results of pictures arranged at a first distance and a second distance that can be arranged at different distances, detect a tilt error and an offset of a ranging characteristic.

[0113] S402. Detect an offset of a distance measurement characteristic according to the distance measurement results of the pictures arranged at the first distance.

[0114] S403. For the central portion of the filling layer, determine an adjustment value of the ranging error by using the tilt error and the offset of the ranging characteristic.

[0115] S404. For the peripheral portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com