A trenchless pipeline renewal construction system and construction method

A non-excavation and pipeline technology, which is applied in pipeline laying and maintenance, tunneling, earthwork drilling and mining, etc. It can solve the problems of inapplicable underground pipeline complete renewal and volume expansion, pipeline corrosion damage, old pipeline capacity difficult to meet functional requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

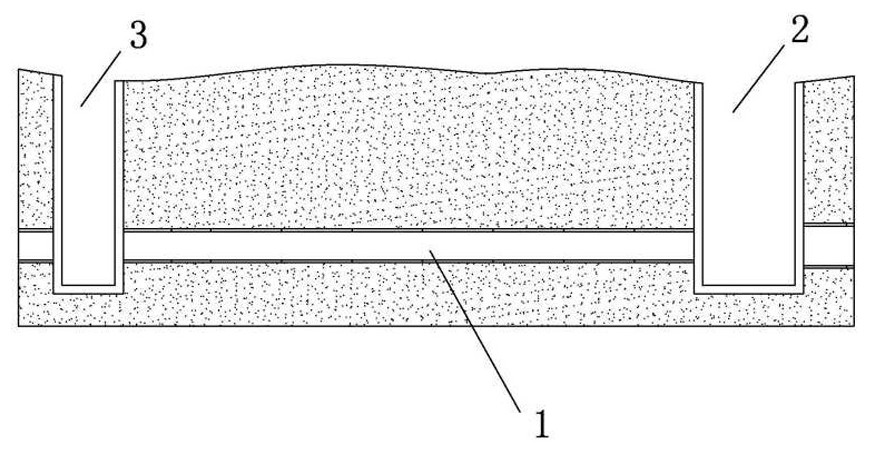

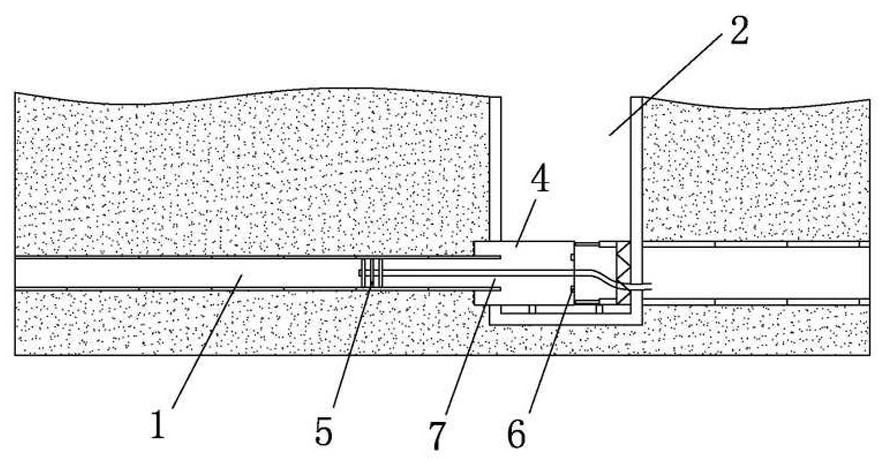

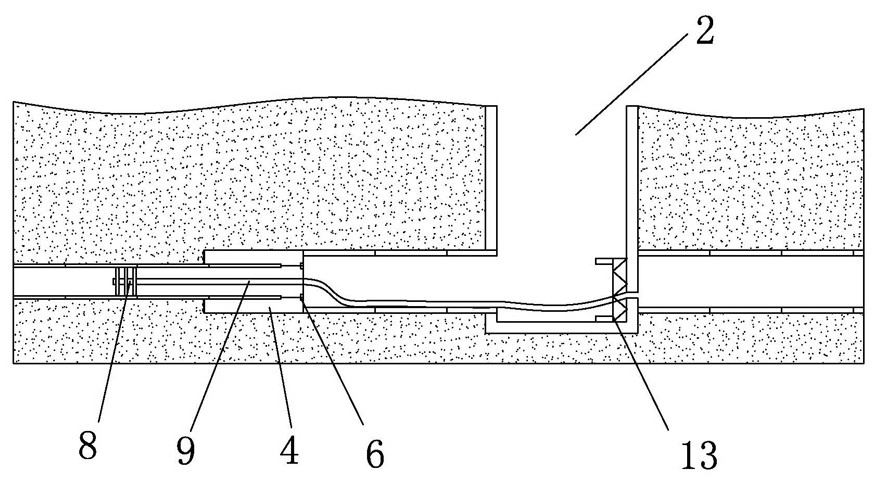

[0039] like Figure 1-10 As shown, a non-excavation pipeline renewal construction system is provided. The construction system adopts the non-excavation construction process to carry out the pipeline replacement construction of the node pipeline section and the expansion construction of the pipe section for the existing underground pipeline; the construction system includes There is an existing underground pipeline 1, and an originating shaft 2 and a receiving shaft 3 are respectively set at both ends of the existing underground pipeline section to be renewed, wherein the originating shaft is used for the assembly and assembly of tunneling equipment and the starting point of excavation, and the receiving shaft is used for Hoisting and recovery of equipment after excavation; a tunneling device 4 is arranged in the originating shaft, and the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com