Submerged arc furnace electrode slipping hydraulic system

A technology of electrode pressing and releasing and hydraulic system, applied in the field of submerged arc furnace, can solve problems such as electrode breaking, and achieve the effect of avoiding electrode breaking, saving carbon electrode resources and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to solve the defect that the existing electrode pressing and releasing device is easy to break the electrode, the embodiment of the present invention provides a submerged arc furnace electrode pressing and releasing hydraulic system, which can effectively protect the three-phase electrodes of the submerged arc furnace and avoid three-phase The phase electrode breakage occurs due to the out-of-control of the upper and lower brakes of the phase electrode.

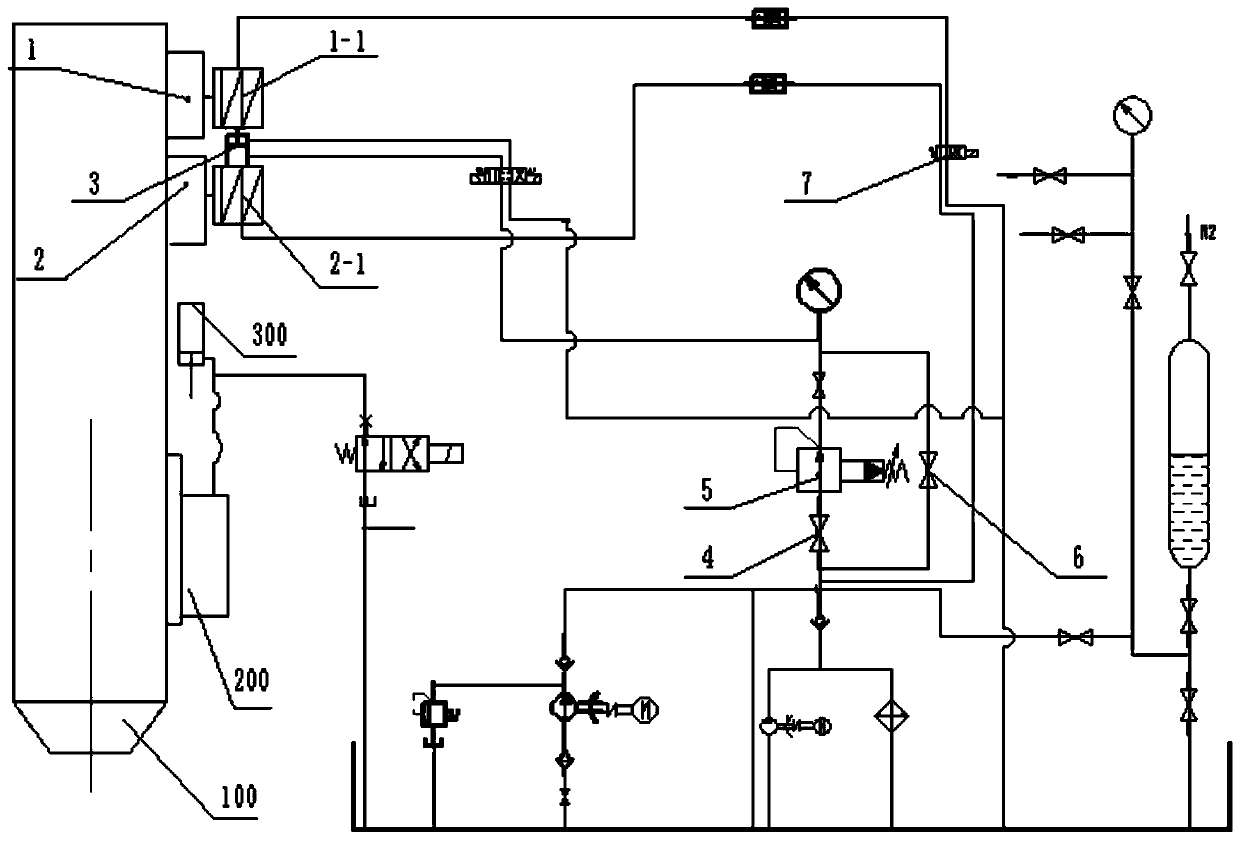

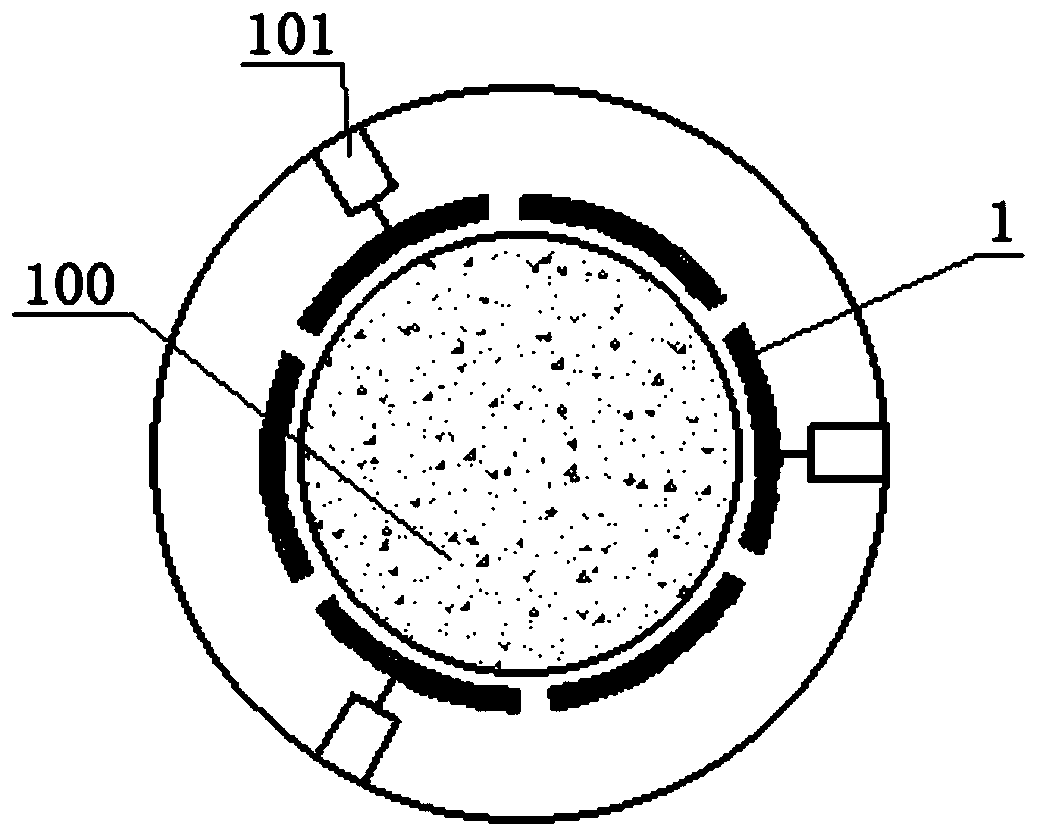

[0020] Such as figure 1 As shown, the submerged arc furnace electrode pressure release hydraulic system includes an upper brake 1, a lower brake 2, and a pressure release cylinder 3 arranged between the upper brake 1 and the lower brake 2. The upper brake 1 It is connected with the upper brake cylinder 1-1, through which the upper brake cylinder 1-1 controls the opening and tightening of the brake shoe of the upper brake 1, and the lower brake 2 is connected with the lower brake cylinder 2-1, through which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com